Warranty

Warranty malfunctions occurring under conditions of normal use in con-

formity with the Instruction Manual and Product Precautionary Mark-

ings will be repaired free of charge. This warranty is valid for a period

of one (1) year from the date of purchase. Please contact the distribu-

tor from which you purchased the product for further information on

warranty provisions.

Introduction

Thank you for purchasing the HIOKI Model CT9691, CT9692,

CT9693 Clamp on AC/DC Sensor. To obtain maximum perfor-

mance from the device, please read this manual first, and keep

it handy for future reference.

Initial Inspection

When you receive the device, inspect it carefully to ensure that

no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evi-

dent, or if it fails to operate according to the specifications, con-

tact your dealer or Hioki representative.

Maintenance and Service

• To clean the device, wipe it gently with a soft cloth moistened

with water or mild detergent. Never use solvents such as

benzene, alcohol, acetone, ether, ketones, thinners or gaso-

line, as they can deform and discolor the case.

• If the device seems to be malfunctioning, contact your dealer

or Hioki representative.

• Pack the device so that it will not sustain damage during ship-

ping, and include a description of existing damage. We do not

take any responsibility for damage incurred during shipping.

• When disposing of the unit, do so in accordance with all

applicable local regulations.

This manual contains information and warnings essential for

safe operation of the device and for maintaining it in safe oper-

ating condition. Before using it, be sure to carefully read the fol-

lowing safety precautions.

Safety Symbol

The following symbols in this manual indicate the relative impor-

tance of cautions and warnings.

Symbols for Various Standards

Measurement Categories

This device complies with CAT III safety requirements.

To ensure safe operation of measuring instruments, IEC 61010 estab-

lishes safety standards for various electrical environments, categorized

as CAT II to CAT IV, and called measurement categories.

CAT II: Primary electrical circuits in equipment connected to an AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

CAT III: Primary electrical circuits of heavy equipment (fixed installa-

tions) connected directly to the distribution panel, and feed-

ers from the distribution panel to outlets.

CAT IV: The circuit from the service drop to the service entrance, and

to the power meter and primary overcurrent protection device

(distribution panel).

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Instrument Installation

Preliminary Checks

Before using the device for the first time, verify that it operates

normally to ensure that no damage occurred during storage or

shipping. If you find any damage, contact your authorized Hioki

distributor or reseller.

The CT9691, CT9692, and CT9693 Clamp on AC/DC Sensors

are designed to be used with the 3290 and 3290-10 Clamp on

AC/DC HiTesters or the CT6590 Sensor Unit (collectively, “in-

struments”).

The 3290 and 3290-10 automatically detect the sensor when it

is connected and set the range accordingly. This combination of

equipment can be used to measure DC, AC, and AC+DC cur-

rent in live lines.

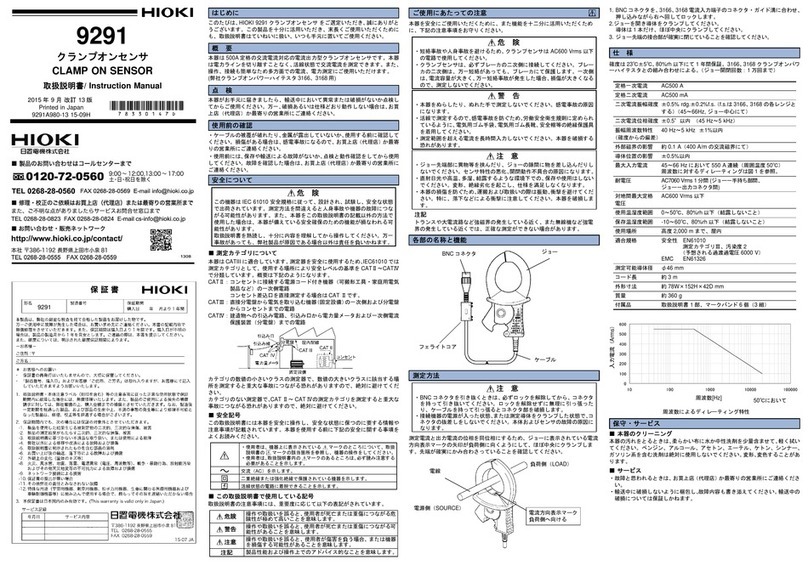

CT9691 Clamp On AC/DC Sensor

CT9692, CT9693 Clamp On AC/DC Sensor

Perform the following inspection before starting measurement:

Do not attempt to modify, disassemble or repair the

device; as fire, electric shock and injury could result.

Safety

CT9691,CT9692,CT9693

CLAMP ON AC/DC SENSOR

Instruction Manual

Sept. 2015 Revised edition 2

Printed in Japan

CT9691A981-02 15-09H

EN

This device is designed to comply with IEC 61010 Safety

Standards, and has been thoroughly tested for safety

prior to shipment. However, mishandling during use

could result in injury or death, as well as damage to the

device. Using the device in a way not described in this

manual may negate the provided safety features.

Be certain that you understand the instructions and pre-

cautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting

directly from device defects.

In the manual, the symbol indicates particularly impor-

tant information that the user should read before using the

device.

The symbol printed on the device indicates that the

user should refer to a corresponding topic in the manual

(marked with the symbol) before using the relevant

function.

Indicates a double-insulated device.

Indicates that the instrument may be connected to or dis-

connected from a live circuit.

Indicates that incorrect operation presents an extreme haz-

ard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant haz-

ard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

injury to the user or damage to the device.

Indicates advisory items related to performance or correct

operation of the device.

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

This symbol indicates that the device conforms to regula-

tions set out by the EC Directive.

• Using a measuring instrument in an environment desig-

nated with a higher-numbered category than that for

which the instrument is rated could result in a severe

accident, and must be carefully avoided.

• Using a measuring instrument without categories in an

environment designated with the CAT II to CAT IV cate-

gory could result in a severe accident, and must be

carefully avoided.

Operating Precautions

Avoid the following locations that could cause an accident or damage

to the instrument.

Exposed to

direct sunlight

Exposedtohigh

temperature

In the presence

of corrosive or

explosive gases

Exposed to

water, oil, other

chemicals, or

solvents

Exposedtohigh

humidity or con-

densation

Near induction

heating systems

(e.g., high-fre-

quency induc-

tion heating

systems and IH

cooking uten-

sils)

Exposed to

strong electro-

magnetic fields

Near electro-

magnetic radia-

tors

Operating temperature and

humidity range:

0°C to 40°C (32 to

104°F), 80% RH or less; no con-

densation

Storage temperature range: -10°C

to 50°C (14°F to 122°F), 80% RH

or less; no condensation

• Attempting to do so could cause a short cir-

cuit or accident resulting in injury or death.

• To avoid electric shock, do not remove the

device's case. The internal components of

the device carry high voltages and may

become very hot during operation.

• To avoid electric shock when measuring live

lines, wear appropriate protective gear,

such as insulated rubber gloves, boots and

a safety helmet.

To avoid damaging the sensor, do not input a cur-

rent in excess of the maximum input range. The

maximum input range varies with the frequency of

the measurement current. Note that continuously

inputting a high frequency will cause the clamp sen-

sor to generate heat.

• The tips of the clamp sensor are extremely delicate. Exer-

cise care in handling the sensor as deformation of the clamp

sensor or damage to the clamp surface caused by dropping

the sensor or bumping it into other objects may prevent ac-

curate measurement.

• Keep the clamp jaws and core slits free from foreign objects,

which could interfere with clamping action.

• To prevent cable damage, do not step on cables or pinch

them between other objects. Do not bend or pull on cables

at their base.

• Measurements are degraded by dirt on the mating surfaces

of the clamp on sensor, so keep the surfaces clean by gently

wiping with a soft cloth.

Overview

Parts Names

Pre-Operation Inspection

No. Inspection step

(Continue inspection if OK.) Corrective action

(Perform when unit fails

inspection.)

1Is the clamp cracked or dam-

aged? If there is any damage, electric

shock may result. Discontinue

use and have the sensor

repaired.

2 Is the cable insulation torn?

3Is there a broken connection

involving the connector or sen-

sor base?

You will not be able to perform

proper measurement. Cease

use and contact your dealer.

1

Perform zero-adjustment.

2

Connect the clamp sensor to the measurement target.

3

Remove the clamp sensor after measurement is complete.

4

Model CT6590

Measuring

instrument

Model 3290, 3290-10

Lever

Output

connector

Clamp sensor

Front side Back side

Sensor lock

lever

LOCK

position

UNLOCK

position

Cable

Protective

barrier

Output

connector

Lever

Cable

Protective

barrier

Clamp sensor

CT9692 CT9693

Lever