Hisense AVWW-76UE(8)SB User manual

Other Hisense Air Conditioner manuals

Hisense

Hisense AUD-18UX4SGKL Operating instructions

Hisense

Hisense AP-10CR1SEJS User manual

Hisense

Hisense AW0621CR1W Technical manual

Hisense

Hisense TDXA180AG Technical specifications

Hisense

Hisense AS-13UR4SYDTDI User manual

Hisense

Hisense AS-18UR4STVUH1 User manual

Hisense

Hisense ADT-12UX4SSNL3 Operating manual

Hisense

Hisense AP-10CW1SGRS00 Installation guide

Hisense

Hisense AVD-07UXCSAL Instruction Manual

Hisense

Hisense AUD-24UX4SZLH Operating manual

Hisense

Hisense AVWT-76FKFSHA Release Note

Hisense

Hisense APC12 Technical manual

Hisense

Hisense AS-07HR4SYDTG User manual

Hisense

Hisense T1 Series Operating manual

Hisense

Hisense AS-09HR4SVCUH User manual

Hisense

Hisense KF-1802GWE Parts list manual

Hisense

Hisense AVWT-408FHFSHA User manual

Hisense

Hisense DC Inverter Unitary Series Technical manual

Hisense

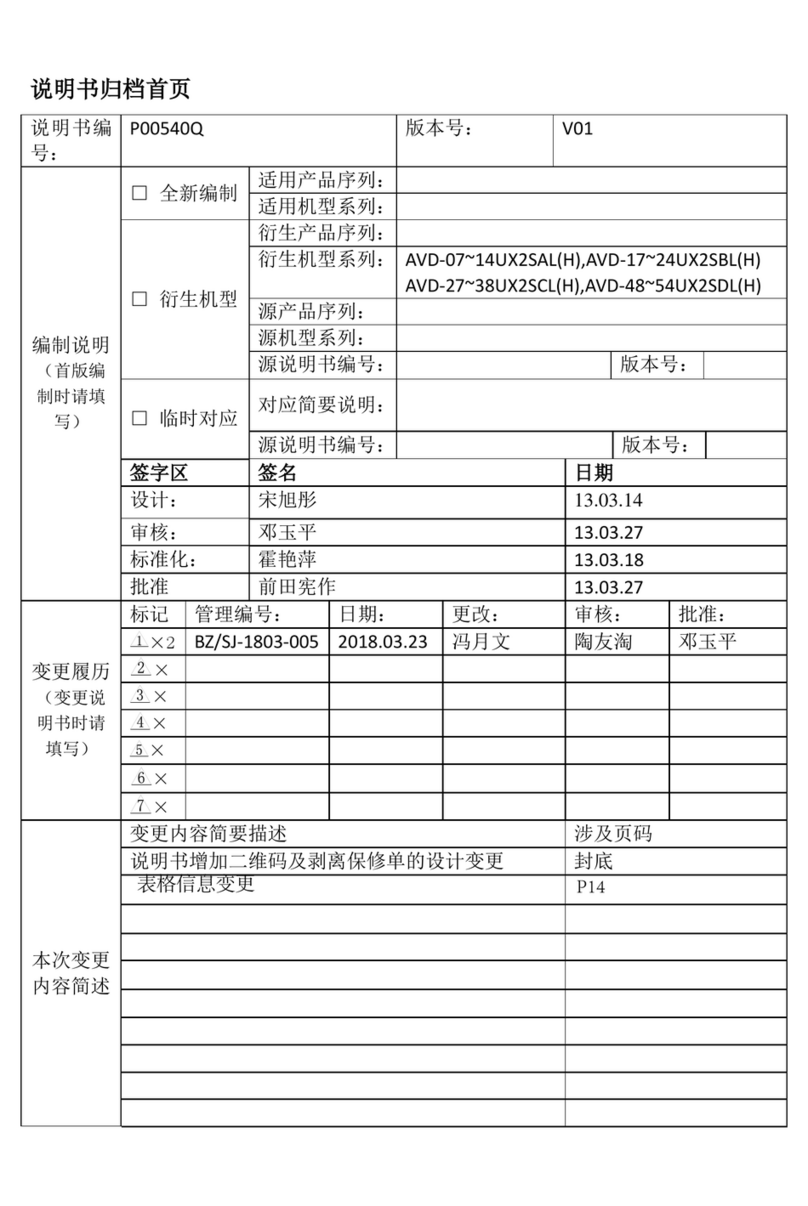

Hisense AVD-07UX2SAL Manual

Hisense

Hisense AMS-07UR4SNZA3 User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions