TESTING

Test communications between the detector and the control panel. The detector

mode has two test buttons; one for smoke testing and one for CO testing.

The detector may also be functionally tested using canned smoke and canned

CO. If the detector fails any of the test methods, the detector should be replaced.

NOTE: Testing the detector will activate the alarm and send a signal to the

panel. Before testing, notify the proper authorities to avoid any

Smoke Test (Alarm Test)

Press and hold the Smoke Test button for 1 to 2 seconds. The detector will sound

and illuminate per Table 2 and send a smoke alarm signal to the control panel (all

programmed smoke detector loops are signaled). Verify that the smoke alarm

signal was received at the control panel.

Smoke System Test (Functional Smoke Test)

CANNED SMOKE NOTE: Detector sounds an alarm when using canned smoke ONLY when in Functional Test mode (canned smoke does not cause

alarm sounding when in normal mode.)

Press and hold the Smoke Test button for 3 to 5 seconds to enter the functional smoke test mode. See Functional Smoke Test section below.

Functional Smoke Test

With the detector in smoke system (functional) test mode, spray canned smoke into the detector. The canned smoke that can be used and is approved

for test include: Home Safeguard Industries 25S, SDi CHEK02 and CHEK06, SDi SOLOA4, and SDi SMOKESABRE.

1. The detector will sound and illuminate per Table 2 and a smoke alarm signal will be sent to the panel.

2. Verify the smoke alarm signal was received by the control panel.

CO Test (Alarm Test)

Press and hold the CO Test button for 1 to 2 seconds. The control panel should display and sound a CO alarm (all programmed CO detector loops are

sent).

CO System Test (Functional CO Test)

CANNED CO NOTE: Detector sounds an alarm when using canned CO ONLY when in Functional Test mode (canned CO does not cause alarm

sounding when in normal mode.)

Press and hold the CO Test button for 3-5 seconds to enter the functional gas test mode. See Functional Gas Test section below.

Functional Gas Test

Solo C6 brand canned CO may be used to verify the detector’s ability to sense CO by utilizing the RealTest® feature as follows:

1. Press and hold the CO test button for 3 to 5 seconds. The green LED will start blinking once per second indicating the detector is in RealTest® mode.

(If the detector will not go into RealTest® mode, the CO sensor may be in fault or at end-of-life.)

2. While the green LED is blinking once per second, spray a small amount of canned CO directly into the CO gas entry port.

3. Upon successful gas entry and if functioning properly, the detector will go into CO alarm and send an alarm to the control panel.

4. The CO test will automatically clear when the CO clears from the sensor or in 30 seconds if no CO was introduced.

HUSH FEATURE / ALARM SILENCE

If required, the audible alarm for smoke and CO conditions can be silenced for 5 minutes by pushing the “Test/Hush” button. In addition, low battery

chirping can be silenced for 12 hours when the Test/Hush button is pressed.

During a Smoke alarm, if an alarm condition still exists after the 5-minute hush period, the alarm will sound. The hush feature will not operate at levels

above 4%/ft. smoke concentration.

During a CO alarm, if carbon monoxide is still present after the 5-minute hush period, the alarm will sound. The hush feature will not operate at levels

above 350 ppm (parts per million) carbon monoxide.

CO SENSOR END-OF-LIFE FEATURE

When the CO sensor has passed end-of-life, a trouble signal will be sent to the control panel (if programmed). This indicates that the CO sensor inside

the detector must be replaced. If unresolved for 30 days, the detector will chirp every 45 seconds. The typical life of the CO sensor is ten years from the

date of manufacture. It is recommended to periodically check the “Replace by” date located on the label on the back of the detector head.

Table 3: Carbon Monoxide Detector: Events & Contact ID Codes

Loss of RF Supervision (CID 381)

Detector end-of-life/trouble

Sensor trouble - (CID 386) Low Maintenance

Disarmed or Armed = Tamper

RF sensor tamper (CID 383)

Table 4: Smoke and Heat Detector: Events & Contact ID Codes

Smoke or Heat Supervision

Loss of RF Supervision (CID 381)

Detector Maintenance (Needs cleaning)

Smoke Detector High Sensitivity (CID 385)

Disarmed or Armed = Tamper

RF sensor tamper (CID 383)

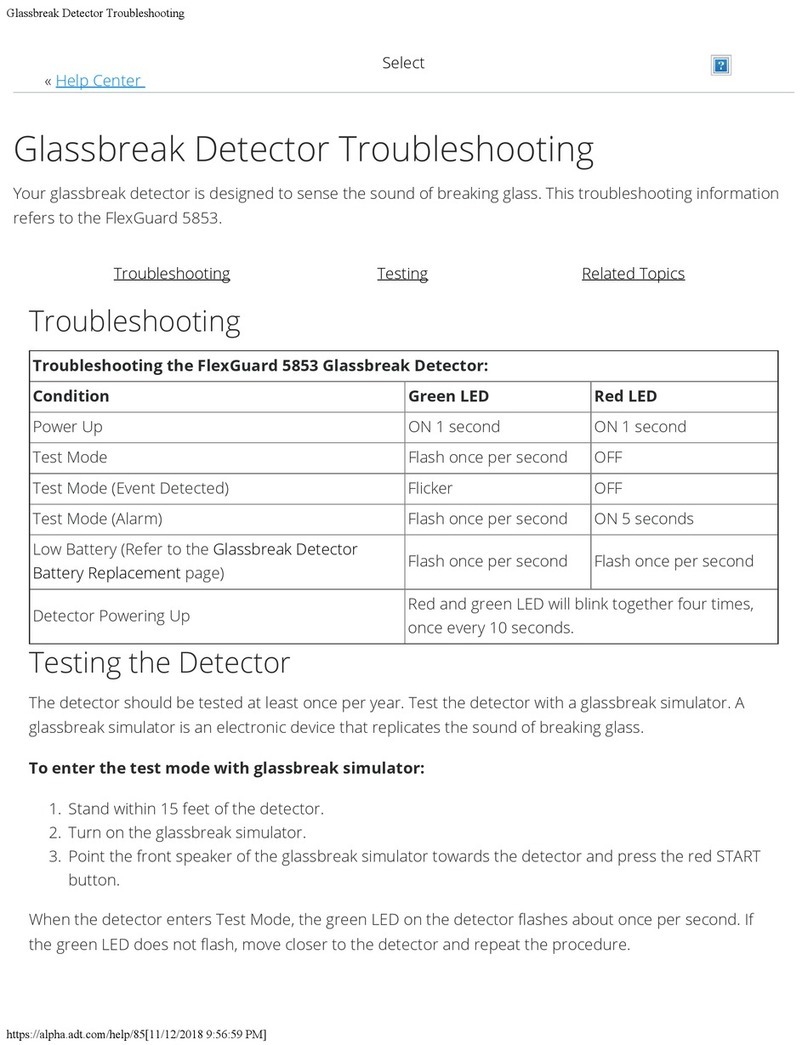

Table 2: LED Indication & Sounder during Test and Trouble

MODE Status LED (Top) Side LED Windows Sounder Speaker

Smoke Test Blink Green once every second Dark Temp-3

Warning of alarm signal transmission.

Voice smoke warning

Functional SMOKE Test – Waiting for canned

smoke entry

Blink Green once a sec Dark Silent

Voice instructions and warning of

alarm signal

Functional SMOKE Test - Successful smoke

entry

Blink Red every 10 secs Blink Red every 10 secs Temp-3 No voice announcment

Functional CO gas entry test – Waiting for gas

Blink Green once per second Dark Silent No voice announcment

RealTest™

Functional CO gas entry test -Upon successful

gas entry

Blink Red once every

10 secs

Blink blue every

10 secs Modified Temp-4 Voice carbon monoxide warning

Low Battery Blink Amber every 10 secs Dark

Chirp every 45 secs

after 7 days

Voice instruc-tions when chirp is

silenced by pressing either test button

Smoke Maintenance Blink Amber every 5 secs Dark Silent

Voice smoke maintenance instructions

if either test button is pressed

Double Blink Amber every 5 secs

CO End of Life – First 29 days Double Blink Amber every 3 secs Dark Silent

Voice end-of- life instructions when

either test button is pressed

CO End of Life – after 30 days Double Blink Amber every 3 secs Dark Chirp every 45 secs

Voice end-of-life instructions when

either test button is pressed

Power Up Blink Green, for 30 secs Dark Silent

Language set instructions only on first

time power-up

Single Blink Green every 10 secs