ACCESSORIES (order separately):

Capillary compression fittings.

Part No. 104484A: l/2 in. NPT spud.

Part No. 1044848: 314 in. NPT spud.

Immersion well. Pressure rating 255 psi [1760 kPa].

Part No. 45900409-0038: l/2 in. BSPT spud,

1 in. insulation, 3-l /2 in. insertion.

Part No. 45900409-0098: l/2 in. NPT spud,

l-l /2 in. insulation, 3 in. insertion.

Part No. 45900409-0108: 3/4 in. NPT spud,

l-1 /2 in. insulation, 3 in. insertion.

OPTIONAL SPECIFICATIONS (specify when ordering):

l Combination screw and l/4 in. male quick-

connect terminals.

0 High or low limit stop (models with knob only).

0 Mounting bracket (remote bulb models only).

1

I INSTALLATION

WHEN INSTALLING THIS PRODUCT. . .

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

2. Terminal connections must be inside an en-

closure that meets local electrical codes.

LOCATION

The equipment manufacturer generally provides a

tapping for insertion of the temperature controller

sensing element The tapping should be located at a

point where average system temperature will be mea-

sured. Never locate the sensing element close to a hot

or cold water inlet or a steam coil, or where the well’s

pressure rating will be exceeded.

Turn off power and, if the system is filled, drain to a

point below the boiler tapping or wherever the sensing

element is to be located. If no tapping is provided,

prepare one, properly threaded, at the desired location.

If this is a remote bulb unit, the controller case can be

mounted in a panel or, with the optional bracket, on any

flat surface. Choose a location within reach of the

sensing element. Allow for gradual bends and some

slack in the capillary.

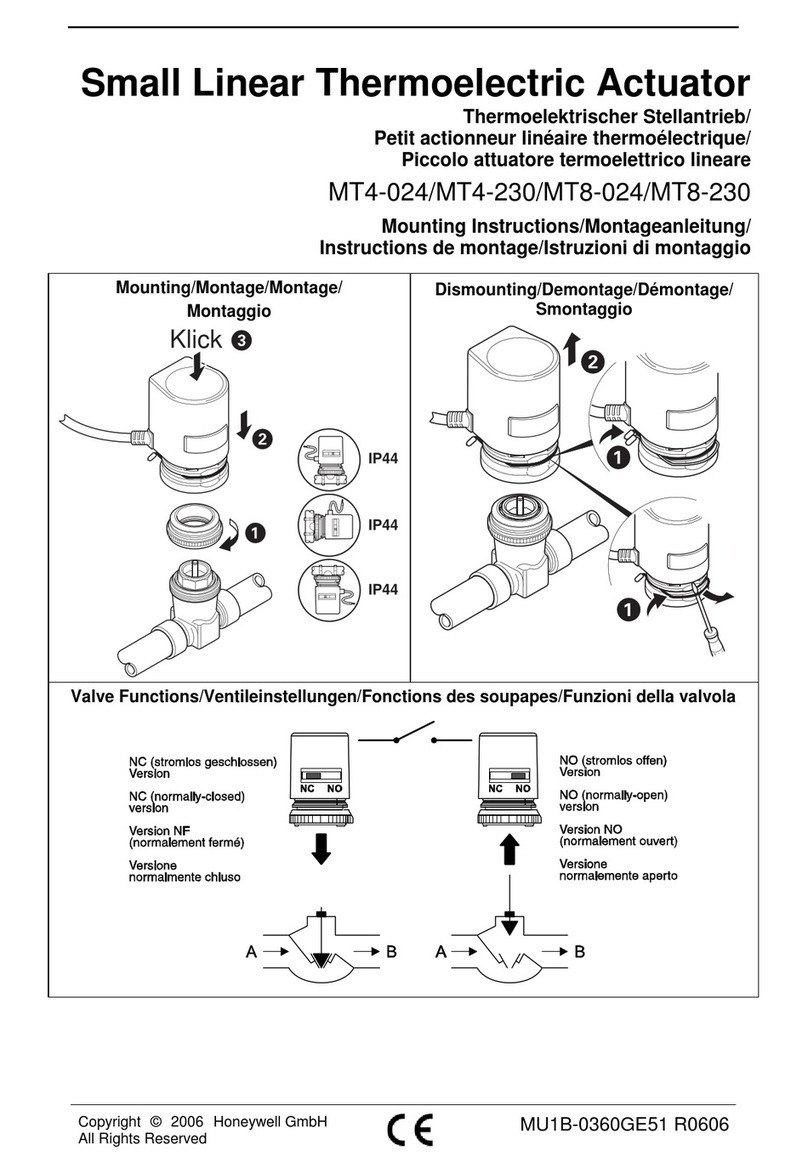

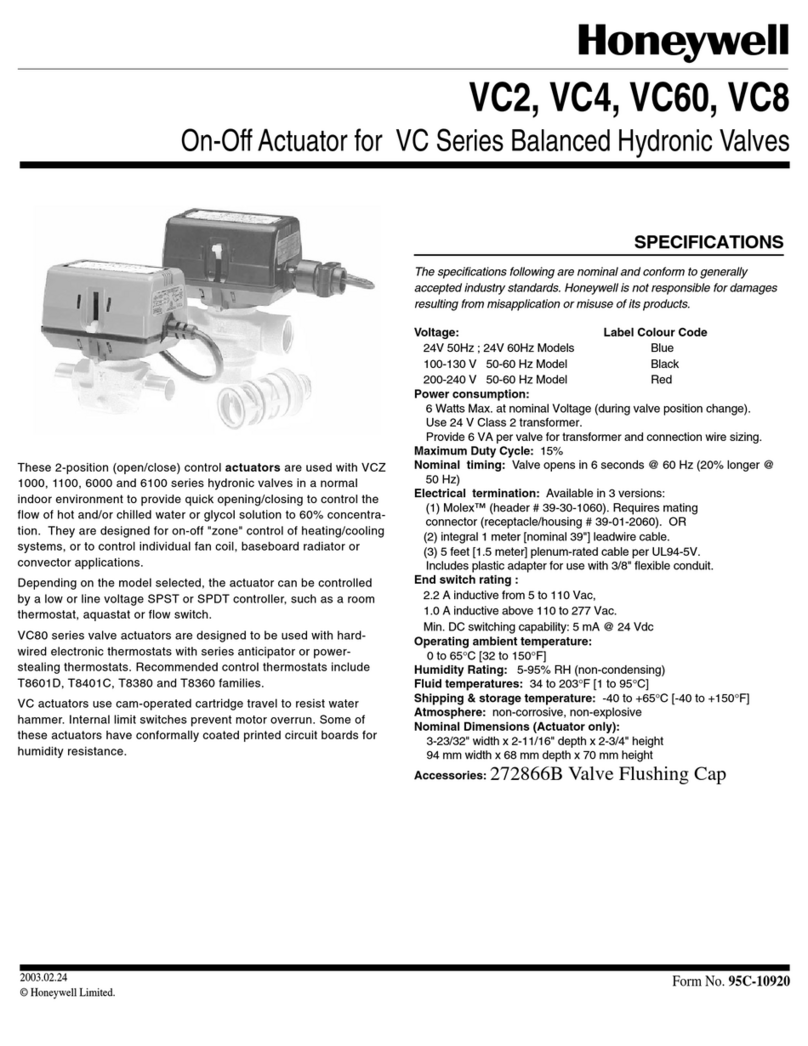

MOUNT THE IMMERSION WELL

1. Coat the well threads with a moderate amount of

pipe dope, leaving two end theads bare. Teflon tape

may also be used.

2. Screw the immersion well into the tapping and

tigthen securely.

3. Refill the system. Check for and correct any leaks.

“SE MODERATE AMOUNT

OF PIPE COMPOUND

12.011 \ LEAVE 2 EN0 THREADS BARE

FIG. P-USE GOOD PIPING PRACTICE WHEN IN-

STALLING IMMERSION WELL.

TO INSTALL DIRECT MOUNT

CONTROLLER

1. Slide the sensing bulb all the way into the well. The

metal collar around the capillary should slip into the

well spud.

2. Line up the case so the setting indicator is on top.

3. Tighten the setscrew in the well spud snugly

against the metal collar.

CONTROLLER

w.03.

FIG. 3-THE DIRECT MOUNT MODEL IS HELD Ih

PLACE BY THE SETSCREW IN THE WELL

SPUD.

TO MOUNT REMOTE BULB

CONTROLLER

INSERT SENSING BULB IN WELL

1. Slide sensing bulb into well. Make sure bulb rests

against the bottom of the well. Don’t bend the capillary

where it connects to the bulb.

2. Hold bulb in place and tighten setscrew all the way

down. It won’t fit tight against the capillary, but it will

keep the bulb from sliding out

CAPIL

FIG. 4-THE SETSCREW KEEPS THE REMOTE SEN-

SING BULB IN THE WELL.