Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

RETROFIT ROUND DAMPER (RRD)

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

69-1960 M.S. 06-06

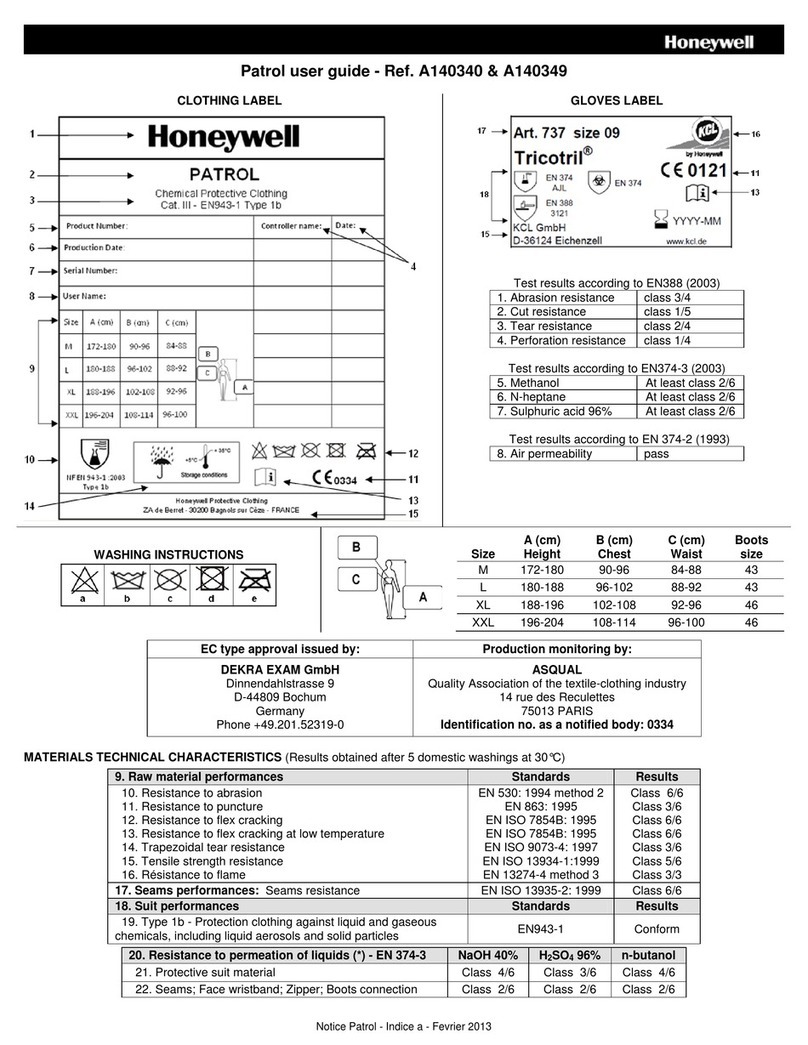

Fig. 6. Wiring multiple RRD dampers using wire nuts.

ADJUSTMENTS

Manual Blade Adjustment

To verify correct range of motion, depress the manual blade

adjustment button. While this is pressed, the gears are

disengaged, allowing the blade to be manually opened or

closed by turning the damper blade shaft. See Fig. 1.

Position Indicator

The position indicator points toward the position of the damper

blade to identify if the blade is open, closed, or at an

intermediate position. A slot at the end of the damper blade

shaft also indicates blade position.

Range stops

The RRD damper motor can be adjusted to prevent complete

closure of the blade. This is useful in zone systems where it is

not possible to install a bypass damper.

To set the range stop to prevent complete closure:

1. Locate the range stop adjustment screw on the top of

the motor to the right blade shaft. This is at the extreme

counter-clockwise end of travel.

2. Using a small Phillips head screwdriver, loosen the set

screw.

3. Move the end-stop block to the new position

4. Secure the set screw.

5. Verify the new range of motion while depressing the

manual blade release button.

CHECKOUT

CAUTION

Possible Equipment Damage

Do not manually open or close the damper unless the

manual blade release button is depressed

To check out the RRD damper using 24 VAC transformer:

1. Connect 24 VAC common to the M1 (common) terminal

on the actuator.

2. Connect 24 VAC hot to the M6 terminal to close the

damper.

3. Observe the blade move clockwise and stop in the

closed position.

4. Remove the 24 VAC hot wire from the M6 terminal.

5. Connect the 24 VAC hot wire to the M4 terminal.

6. Observe the blade move counter-clockwise and stop in

the open position.

7. This verifies correct operation.

To check out the RRD damper when connected to a zone

control panel. (This assumes that the damper has been wired

correctly as shown in Fig. 4.)

1. Begin with all zone thermostats set so that they are not

calling for heat, cool, or fan.

2. To test the damper on zone 1, set the thermostat on

zone 2 to the fan “On” mode so that it calls for fan.

3. This will make the damper on zone 1 close

4. Observe damper one closing on its position indicator.

The damper will take 90 seconds to close.

5. Set zone 2 thermostat to the fan “Auto” mode so that it

is no longer calling for fan. The zone 1 damper will now

return to the open position. This completes the test of

the zone 1 damper.

6. To test the damper on zone 2, set that thermostat on

zone 1 to the fan “On” mode so that it calls for fan.

7. Observe the damper on zone 2 close.

8.

Also observe that zone 3 or others, if connected, also

close when the zone 1 thermostat is in the fan “On” mode.

9. When complete, set the zone 1 thermostat to the fan

“Auto” mode. All zones will now return to the open

position.

10. This verifies correct damper wiring and operation.

TROUBLESHOOTING

RYWGCM6M4M1

RYWG

ZONE

1, 2, 3, ETC.

M1

M6

M4

M1

M6

M4

M23410

ZONE

THERMOSTAT WIRE NUT

Damper operates backwards Verify correct damper wiring as shown in Fig. 4–6.

Damper does not operate 1. Verify damper wiring using checkout methods listed in this document.

2. Verify that the duct is round and not making the blade stick. Depress the

manual blade release button and manually turn the blade shaft to verify

smooth opening and closing operation.