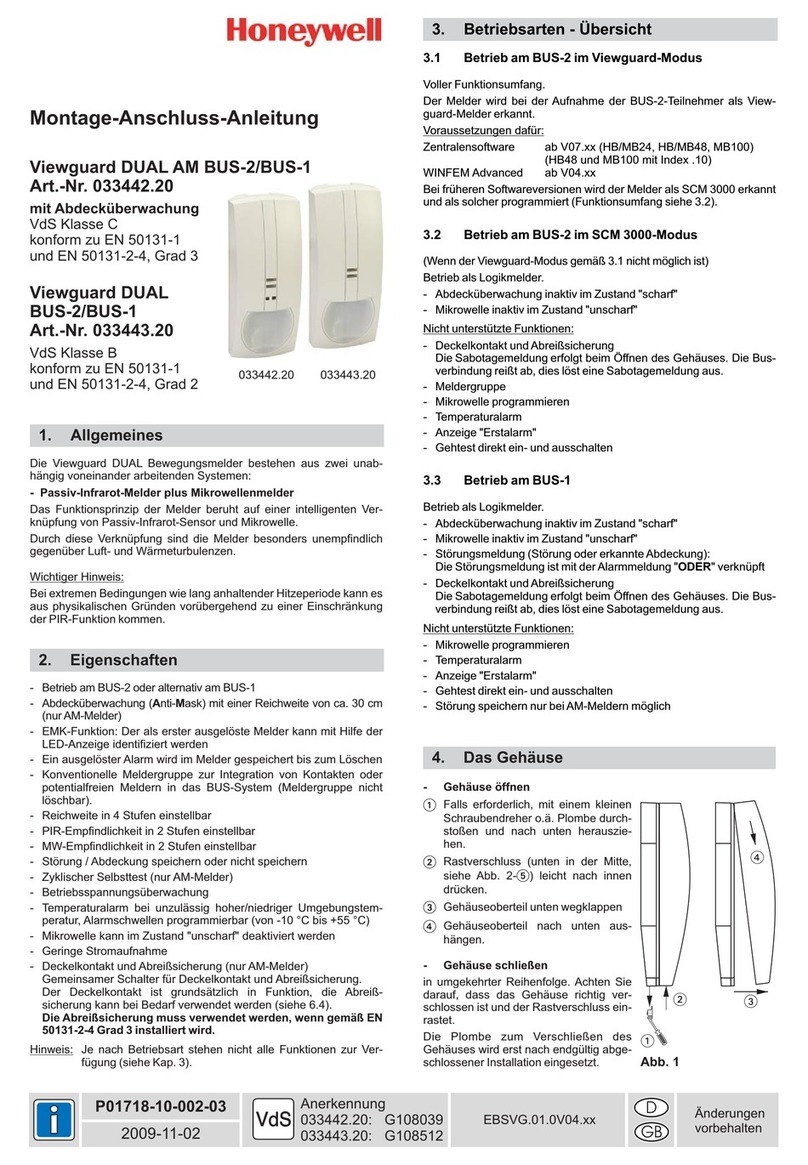

S-Quad Semi-flush

fixing kit (S4-FLUSH)

An S-Quad device can be semi-flush mounted to a ceiling tile to a

depth of the approximate 20mm, which is slightly deeper than the

base assembly. To semi-flush mount a special housing must be

used, which consists of a main assembly and a trim ring.

"There is an enhanced volume output of sound

and speech from a flush mounted S-Quad.

Technical data

Weight 164g with trim ring

Dimensions 174mm diameter by 50mm depth

Enclosure ABS

Colour RAL 9010

Storage Temperature -20°C to 70°C

Ambient temperature -10°C to 50°C

Relative Humidity 95% non condensing

(5 to 45°C)

Further information about

these products can be found

in Part 2 of this document

available on Gent Expert

website.

Data and Installation S-Quad

Gent by Honeywell reserves the right to revise this publication from time to time and make changes to the content hereof without

obligation to notify any person of such revisions of changes.

Hamilton Industrial Park, Waterside Road, Leicester LE5 1TN, UK Website: www.gent.co.uk

Telephone +44 (0) 116 246 2000 Fax (UK): +44 (0)116 246 2300

4 4188-779 issue 8-7_08/10_S-Quad _Part 1

Do not dispose of with your normal household waste.

Do not burn.

WEEE Directive:

At the end of their useful life, the packaging,

product and batteries should be

disposed of via a suitable recycling centre.

At the end of their useful life, the packaging,

product and batteries should be disposed of

via a suitable recycling centre and in

accordance with national or local legislation.

0832

Gent by Honeywell

Hamilton Industrial Park,

140 Waterside Road,

Leicester LE5 1TN, UK

Product EC Certification

No. of Conformity No.

S4-710 0832-CPD-0706

S4-711-VO 0832-CPD-0608

S4-715 0832-CPD-0707

S4-720 0832-CPD-0516

S4-720-ST-VO 0832-CPD-0609

S4-771 0832-CPD-0511

S4-770 0832-CPD-0708

S4-780 0832-CPD-0517

S4-911 0832-CPD-0515

S4-911-ST-VO 0832-CPD-0512

S4-711 0832-CPD-0513

S4-711-ST 0832-CPD-0514

S4-711-ST-VO 0832-CPD-0510

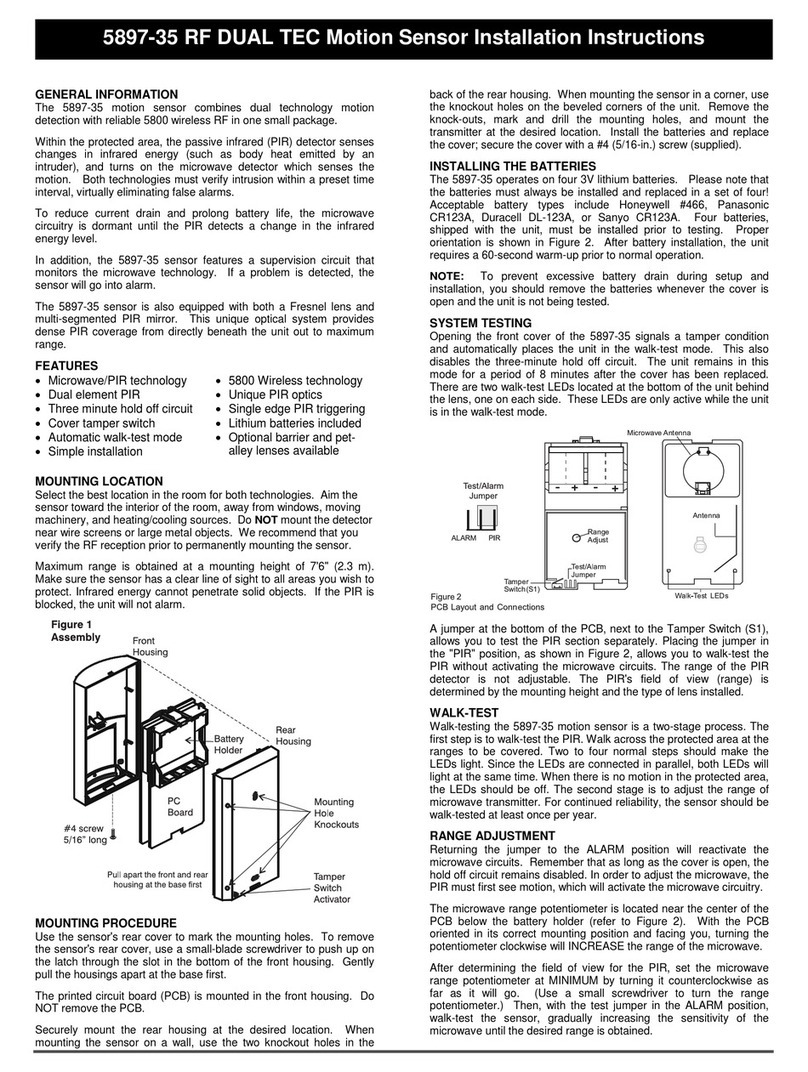

S-Quad

Trim ring

Cross section

of Ceiling Tile

Flush shroud

S-Quad Base

Do not over tighten the clamping

screws as this will cause the

clamps to cut into the ceiling tile.

Metal back box

Cut a 140mm

diameter hole in the

ceiling tile.

(

)

If required use a Bi-Metal Holesaw

140mm or 146mm, from

www.shop4tools.co.uk

Insert the flush shroud

assembly into the hole

in the ceiling tile.

Hold the flush shroud

to the ceiling tile and tighten

the three screws to splay the

clamps to secure the shroud to the tile.

Locate the S-Quad Base into

the flush shroud, such that the

two locating pillars on the

shroud feeds through the two

elongated holes on the Base.

Push the Base into the shroud

until the Base click locks into

the shroud.

Offer the trim ring to the shroud

and slowly rotate ring clockwise until it

clicks and goes no further. This will

lock the ring in position.

Fit the metal box onto the back

of the flush shroud using the

appropriate fixing screws to secure

the box to the flush shroud.

Offer the S-Quad to the Base

and rotate the S-Quad clockwise

until it moves upwards into Base,

and then rotate the S-Quad again

until it clicks and

oes no further.

Make the cable connections.

Clamp

www.acornfiresecurity.com

www.acornfiresecurity.com