Fixing

Only suitably qualified personnel should install this equipment.

1. This is an extremely sensitive movement detector; it is essential therefore that it be installed on a rigid

surface that will not itself be subject to any movement or vibration.

2. Before isolating the circuits to be switched, check that all lighting is fully operational and that there is no

moving equipment or machinery within the monitored area which may cause nuisance switching.

3. Position the detector where it has a good forward “view” of the area to be controlled. Ideal mounting

location is normally in a corner by the entrance or at one end of a corridor at a height of 2.5 to 4m. Do not

mount within 25cm of a fluorescent fitting.

Please note that this product uses microwave technology to detect occupancy and is not recommended

for applications where there are large areas of metal, e.g. metal ceiling or panelling, as unpredictable

sensitivity may result.

Also, microwave presence detection is not completely attenuated by materials such as plasterboard,

wood and glass, so the possibility of unwanted presence detection through office partitions should be

considered when determining detector positioning and sensitivity settings within the intended application.

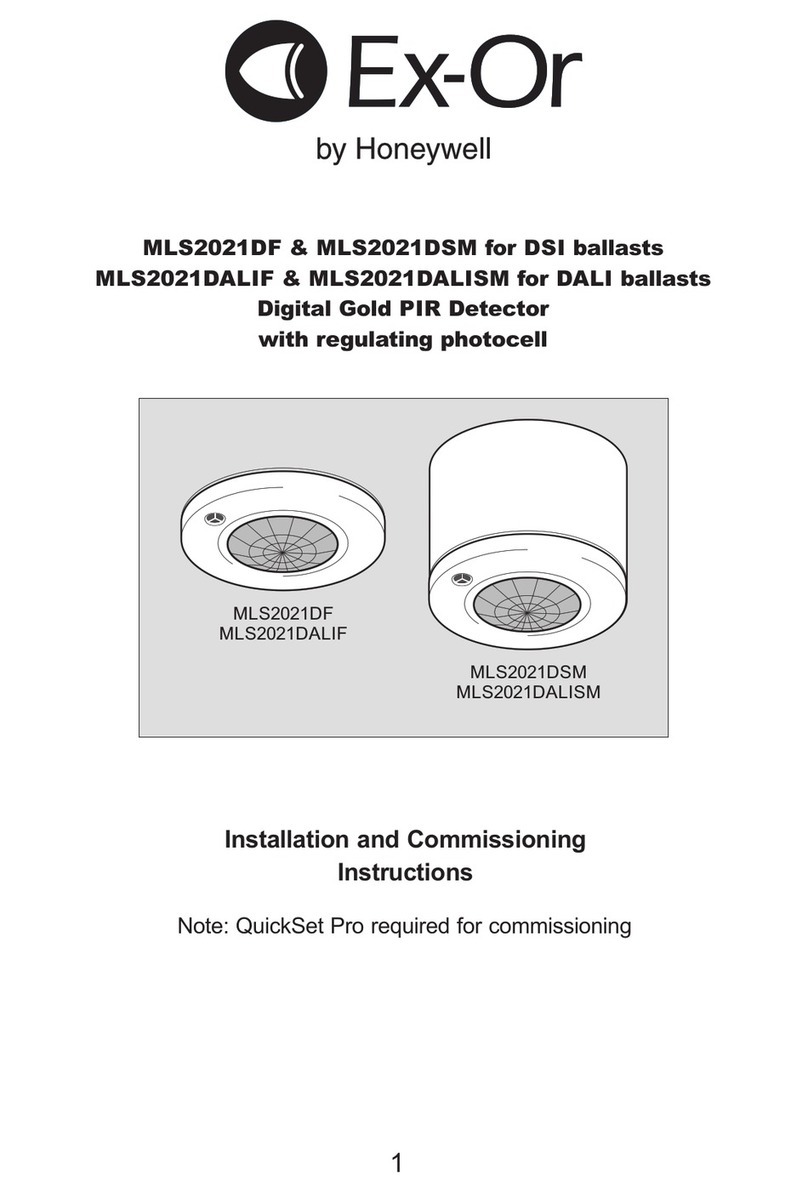

4a. MLS2500D - Surface version

Separate the detector from its back-box by loosening the locking screw so that approximately 3mm of

thread is visible and then twisting the detector off the back-box. Note the arrow symbol moulded into the

bottom of the back-box. The fixing holes allow for mounting on a BESA box or direct to a rigid surface.

Secure the back-box firmly to a rigid surface so that the arrow points into the controlled area.

4b. MLS2500DF- Semi-flush version

Use a hole saw to drill a 76mm hole into the ceiling tile. The flush ring is designed to clamp the tile between

its two halves. Loosen the locking screw so that approximately 3mm of thread is visible and remove the

bottom half of the flush ring. With the detector in the ceiling, pointing towards the area to be controlled, fit

the bottom half of the flush ring to the assembly. Depending on the thickness of the ceiling tile, screws

longer than those supplied may be required to hold the two halves of the flush ring together.

It is recommended that Mid Range detectors be ceiling mounted. Where this is not possible, the wall-mounting

kit (WMK - see below) must be used.

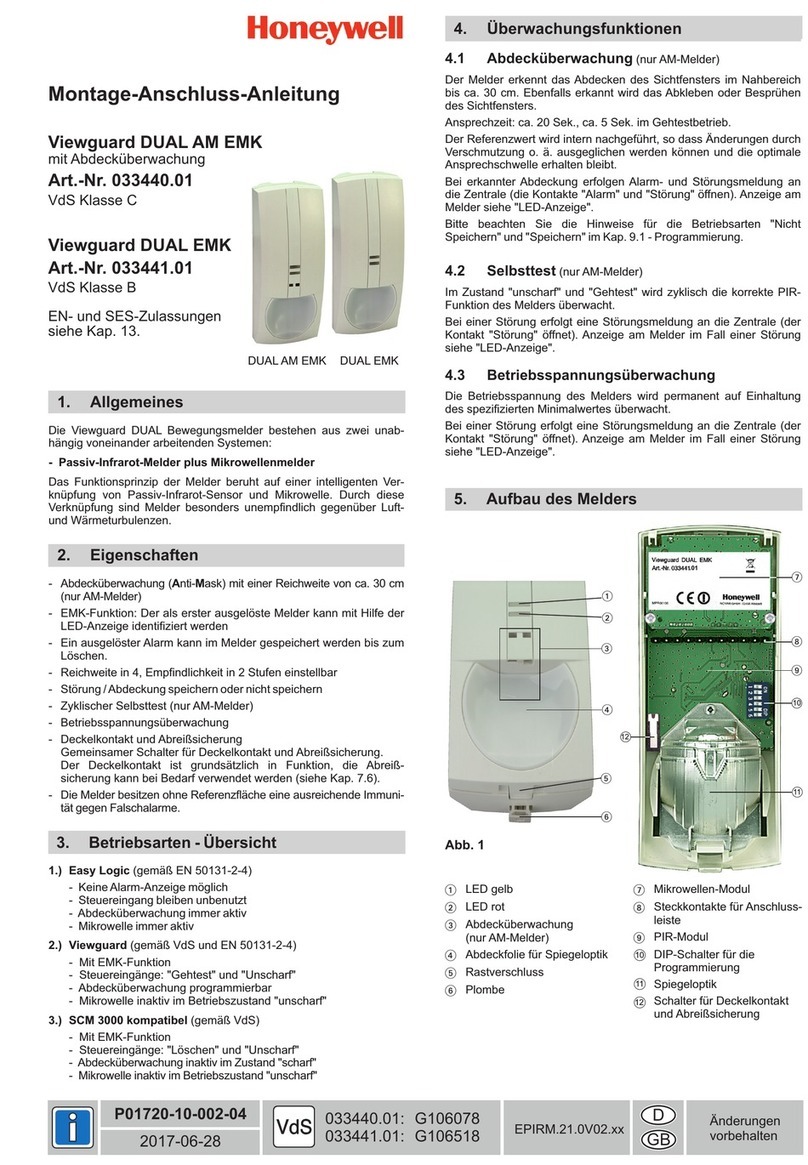

Digital Mid Range Series Detector

WMK Wall-mounting Kit

(Supplied assembled)

Vertical installation

Use this method of mounting for racking aisle

applications and where adjustment in the

vertical plane will give improved control over

the precise point of entry detection.

Horizontal installation

For general applications where

ceiling mounting is not

convenient and wide angle

coverage in the horizontal plane

is desirable. The WMK can be

screwed to a hard surface or the

lid of a conduit stop-end box.

Exploded view of detector

for fixing into ceiling tiles.

2