KSL COMPACT ELECTRONIC AIR FLOW SWITCH – PRODUCT DATA

Manufactured for and on behalf of the Environmental & Energy Solution Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Home and Building Technologies

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0757GE51 R0617

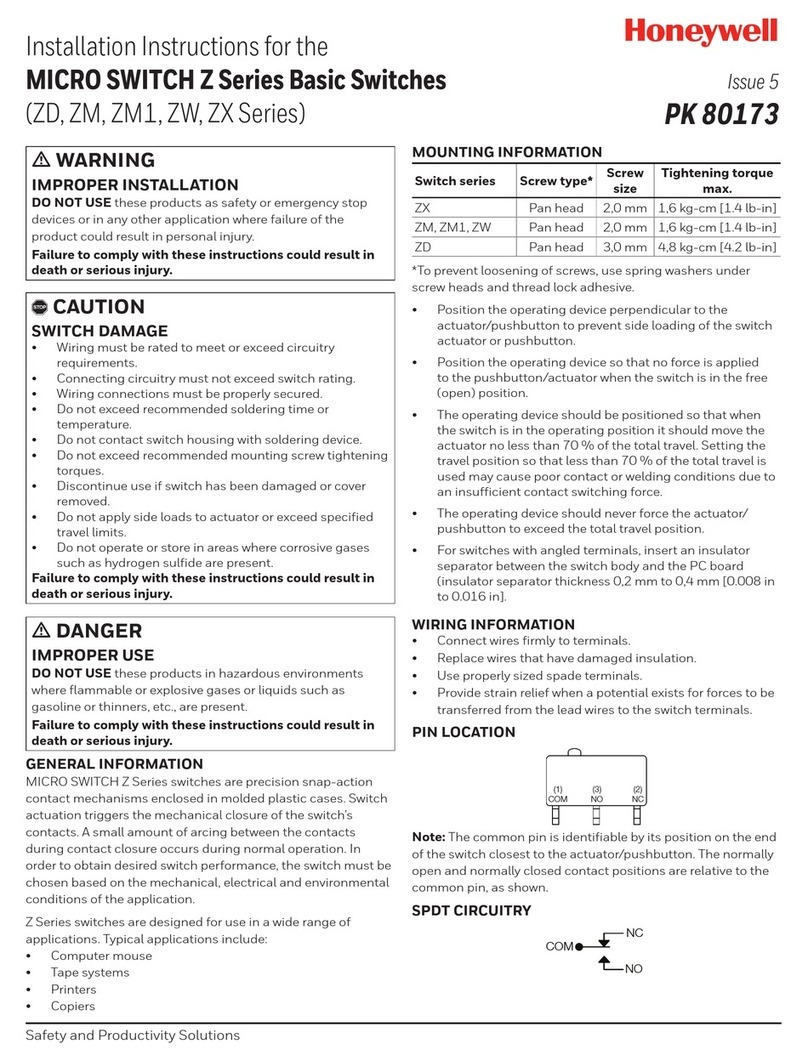

FIELD WIRING

In the case of 230 VAC or 24 VAC power supply, connect the

power supply to terminals L (+) and N (-).

In the case of 24 VDC power supply, connect common 15,

normally-closed 16, and normally-open 18, accordingly.

16 15 18

L(+) N(-)

Fig. 2. Wiring diagram

NOTE: To ensure IP rating, use only cables having diameters of

6…9 mm.

MEASURING PRINCIPLE

The KSL operates according to the principle of the hot-wire

anemometer, and consists of two identical resistive sensors

located inside a probe. One sensor measures the tempera-

ture of the air. The second sensor, located in the lateral

opening and so directly exposed to the air flow, heats up to a

controlled permanent temperature.

When there is no air flow, the temperature of this second,

heated sensor remains stable, but as soon as air flows, its

temperature drops. The resultant change is registered by the

built-in electronics, which attempt to re-establish its original

temperature by increasing the electrical current. The extra

current required to do this is proportional to the air speed.

COMMISSIONING

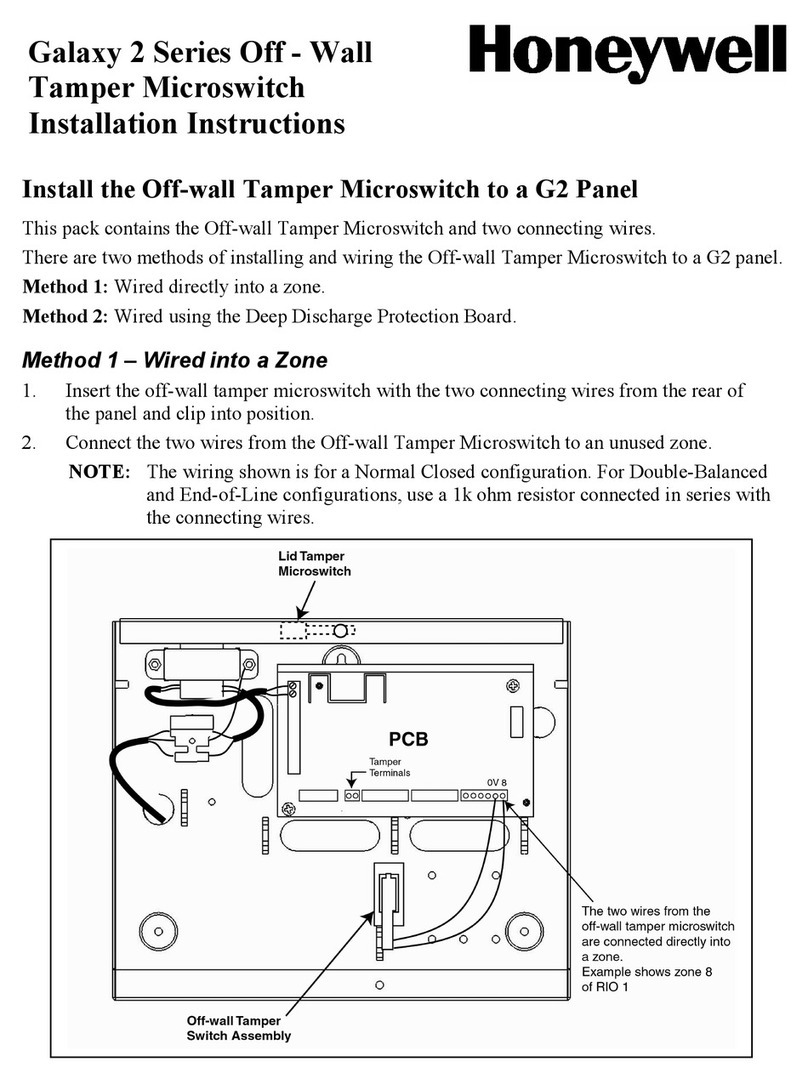

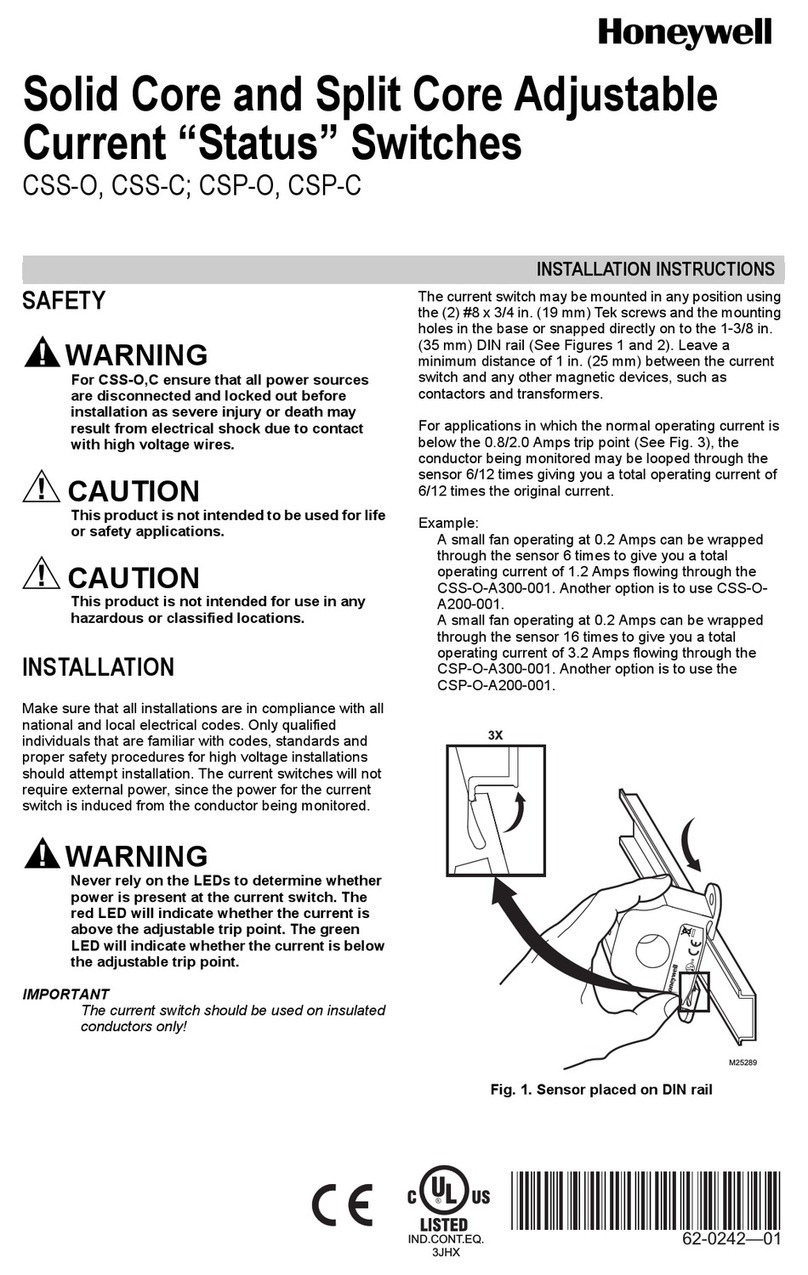

1. If Electrical Outage Protection (see section "60-Second

Electrical Outage Protection") is desired, insert the jumper

(see Fig. 3). Otherwise, remove the jumper.

2. Next, set the potentiometer (marked "Sensitivity" – see

Fig. 3) to the lowest sensitivity (i.e., to the left limit stop).

3. Now connect mains voltage; the green "Voltage" LED will

light up.

NOTE: If the jumper was set, Electrical Outage Protection will now

be in effect (see section "60-Second Electrical Outage

Protection"), and for the next 60 seconds, besides the

green "Voltage" LED, both yellow LEDs ("Time" and "Air

Flow") will also light up, and the device's relay will behave

as though the blower were running and minimum air flow

were present. You must therefore now wait until the 60

seconds have elapsed and the two yellow LEDS have gone

dark before continuing adjustment.

4. Now switch on the blower and provide for nominal air flow.

5. Setpoint adjustment: Slowly turn the potentiometer CW

until the yellow "Air Flow" LED lights up.

6. To achieve a stable switch point, turn the potentiometer

slightly past the switching point.

7. To verify function, reduce or completely cut off the air flow.

The yellow "Air Flow" LED should go dark and the internal

relay should switch.

GREEN "VOLTAGE" LED

ELLOW "TIME" LED

ELLOW "AIR FLOW" LED

JUMPER - OUTAGE PROT.

"SENSITIVITY" POTI

Fig. 3. KSL 24 (cover removed)

60-Second Electrical Outage Protection

The following description of relay behavior assumes that one

wishes to monitor the minimum flow (the usual case). During

normal operation, when the air flow exceeds the setpoint, the

device's relay contact will then close.

To avoid malfunctioning when power is restored after a

system-wide outage (affecting both the blower and the

sensor), select Electrical Outage Protection by setting the

jumper. When restoring power after an outage (or when

starting up; see section "Commissioning"), the relay will then

remain closed for an additional 60 seconds, as though

minimum air flow were still present.

After the 60-sec period has elapsed, normal operation and

relay behavior will resume: Thus, if the air flow has returned

to above the setpoint, the relay will remain closed; if the air

flow has dropped to below the setpoint, the relay will open.

This function can be disabled by removing the jumper.

TROUBLESHOOTING

Problem Possible cause Correction

Device does not

function at all.

No or wrong mains

voltage connected.

Check mains voltage

and connection.

Device does not

detect air flow.

Sensor installed

incorrectly.

Check installation con-

ditions.

Switching behavior

changes.

Sensor heavily

soiled by medium.

Carefully clean sensor

with water.

Device switches at

rapid temperature

increase.

Temp. range is out-

side technical speci-

fications.

Turn poti slightly far-

ther CW. Check temp.

range of system.