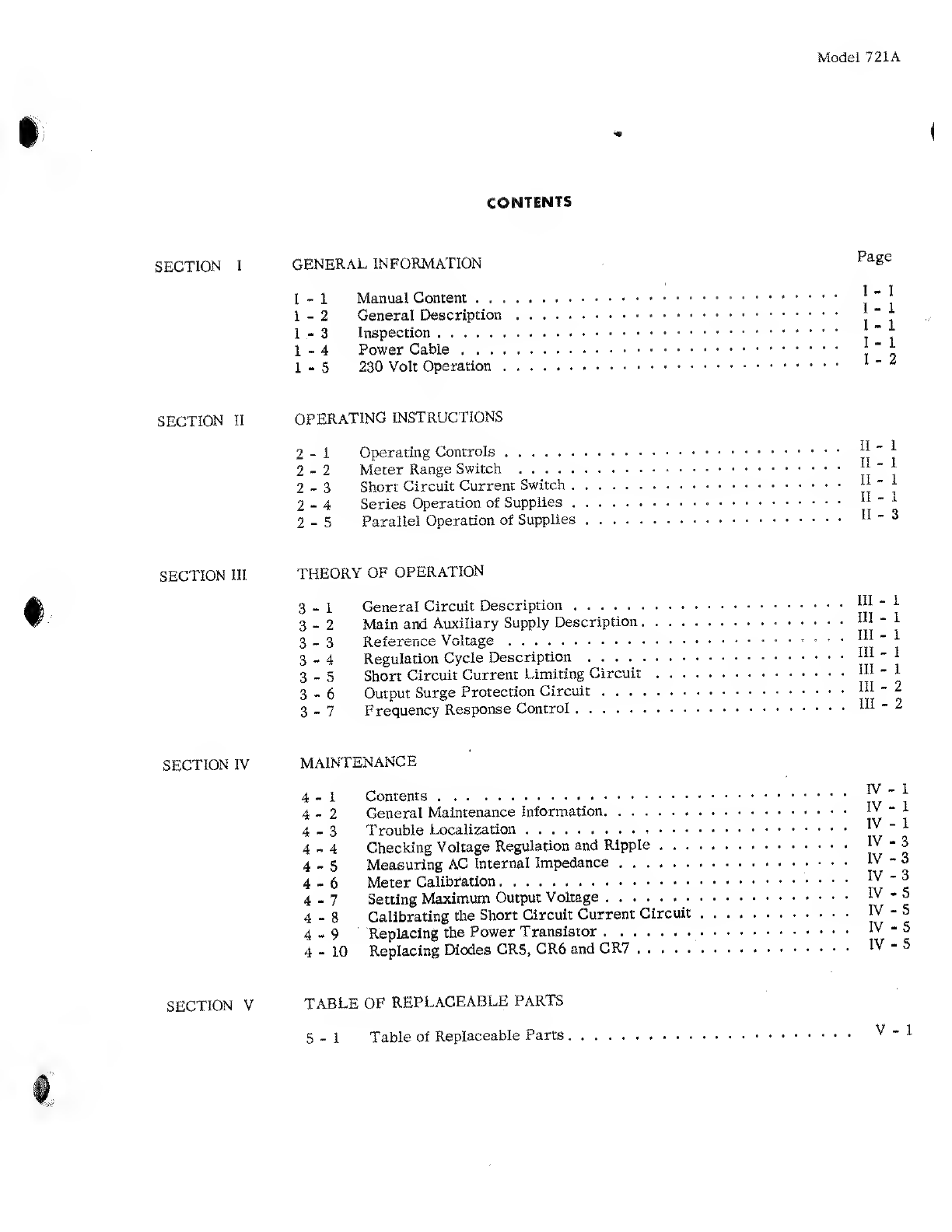

HP 721A Owner's manual

Other HP Power Supply manuals

HP

HP SCR-1P Series Service manual

HP

HP 6434B Service manual

HP

HP 6012A Service manual

HP

HP PSR1800-56A User manual

HP

HP J2962A Installation and operating manual

HP

HP 6236B Service manual

HP

HP D7171A - NetServer - LPr Installation and operation manual

HP

HP D7171A - NetServer - LPr User manual

HP

HP 6259B Service manual

HP

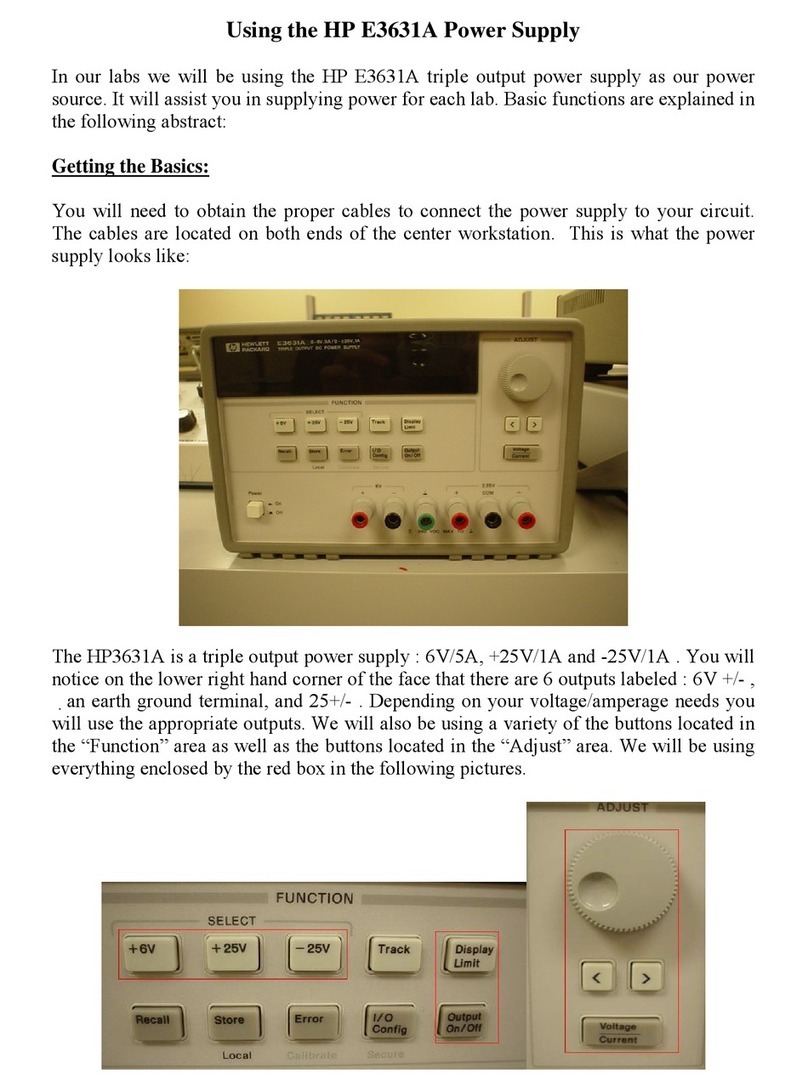

HP E3631A Guide