HP 6259B Service manual

Other HP Power Supply manuals

HP

HP 11900 User manual

HP

HP E3610A Service manual

HP

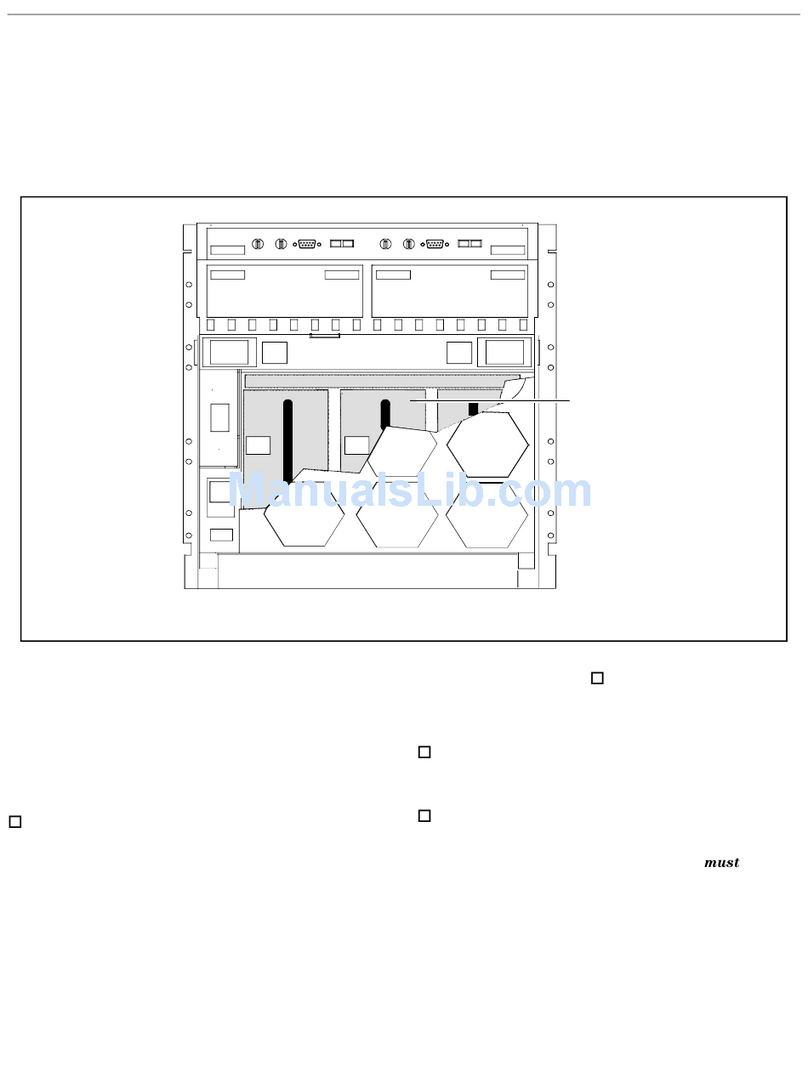

HP procurve switch zl User manual

HP

HP E3620A User manual

HP

HP J2962A Installation and operating manual

HP

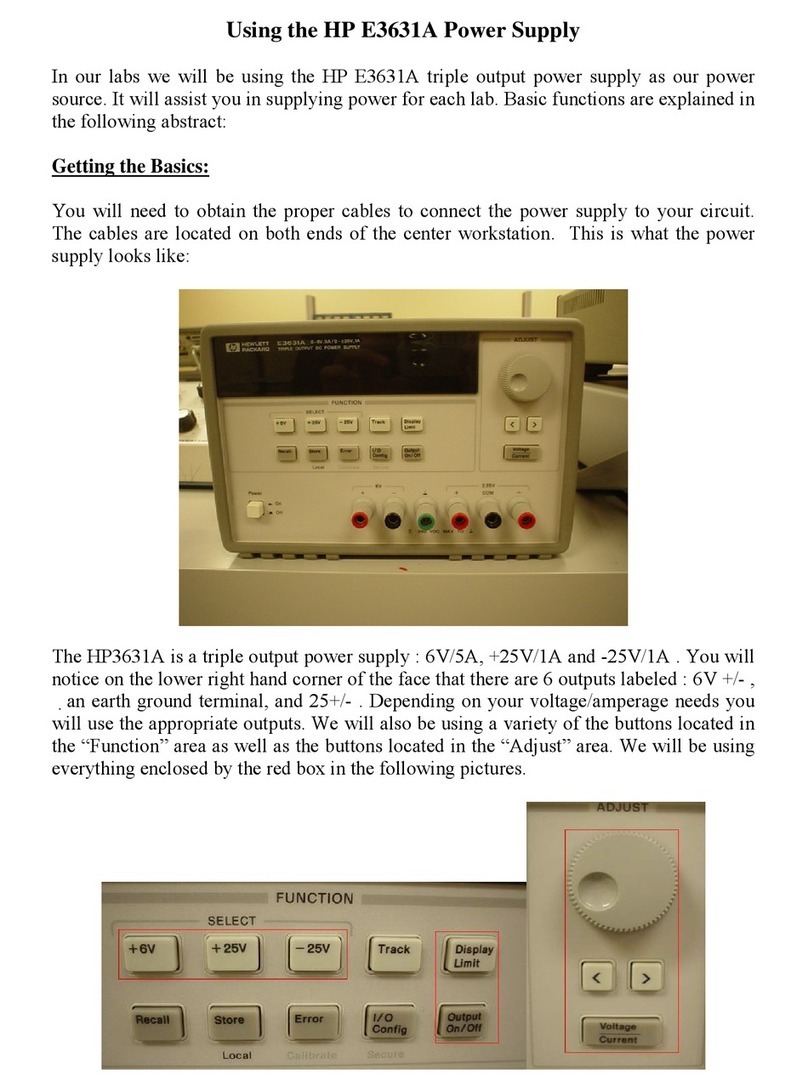

HP E3631A Guide

HP

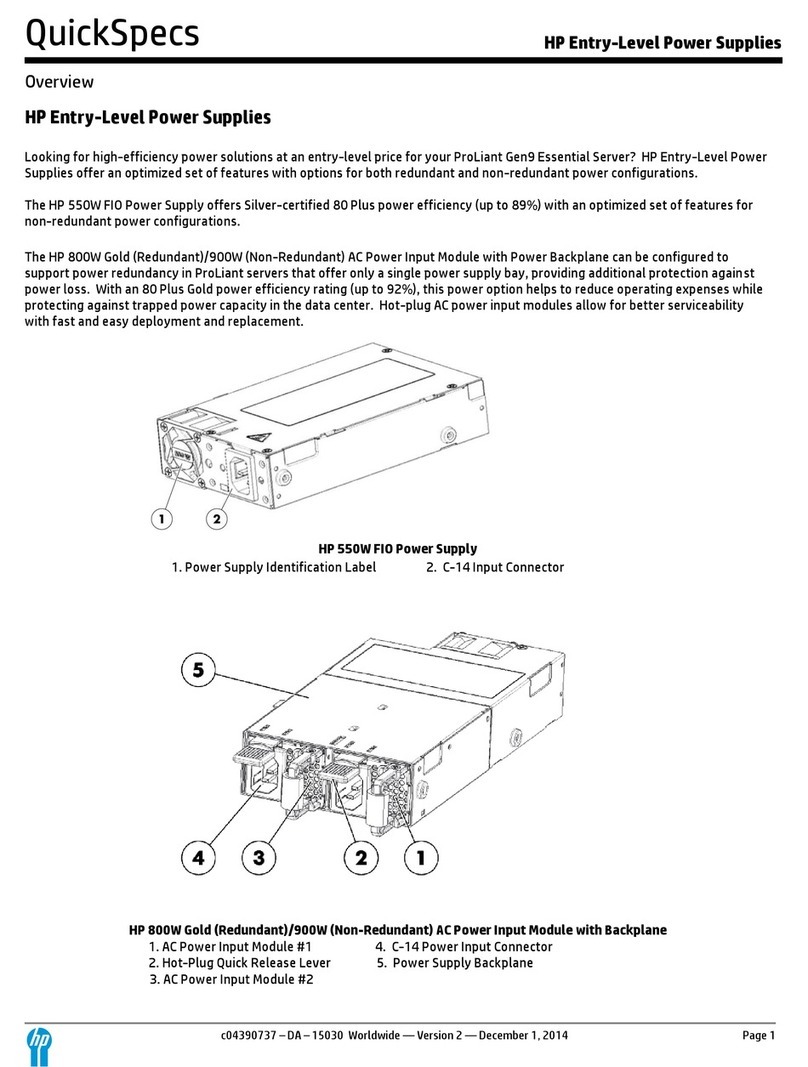

HP Entry-Level User instructions

HP

HP PSR1800-56A User manual

HP

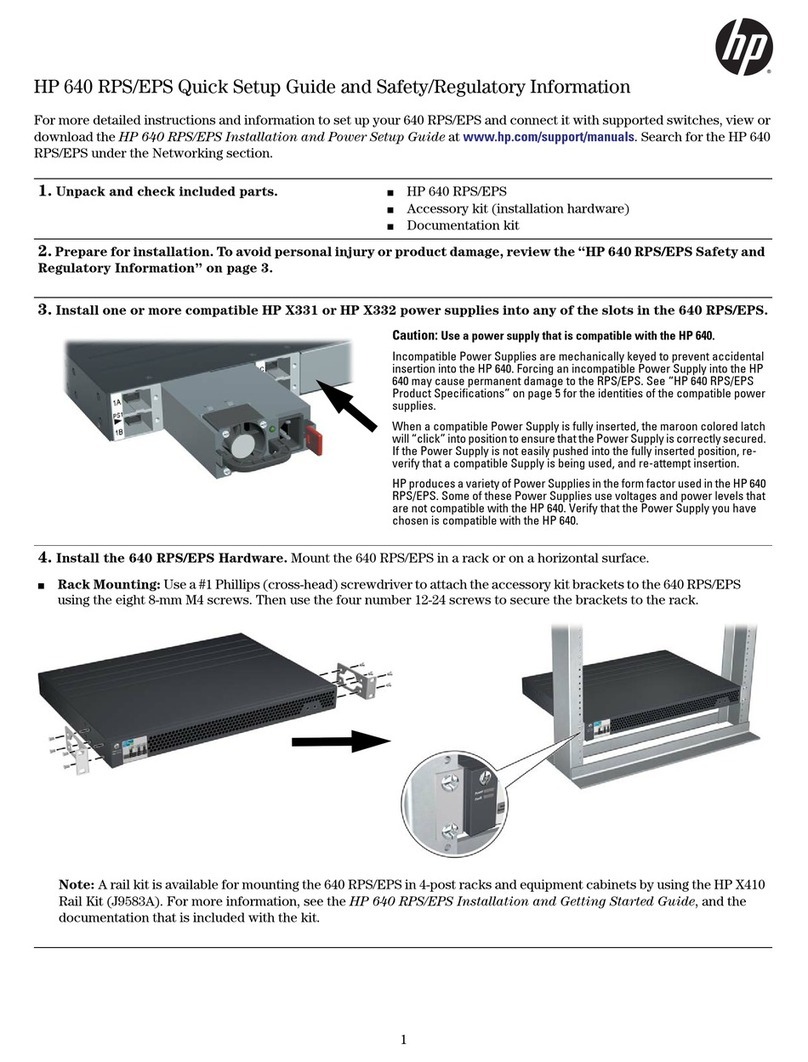

HP 640 RPS/EPS User manual

HP

HP Lab Series Instruction and safety manual