10

The mid-sealing parts have been adjusted properly in the factory, so it is generally

do not need to adjust.

4.5. End sealing mechanism (Rotary type)

1) End sealing knife seat and cutter adjustment

The cutter seat have been adjusted, tested and inspected in a strict way and

generally it does not need make further adjustment. In case adjustment is need,

use two white papers, between which a carbon paper is sandwiched, to test and

check if the pressed marks on the paper are even and clear, if they are clear, the

cutter seat position is correct and no adjustment is required, if not, adjustment to

the cutter seat is required, to adjust, loosen the screw M10 (not completely take

off), then adjust the crossing adjusting screw to correct the position of the cutter

seat, until proper result is reached. At last tighten the screw M10. Adjustment of

the cutter seat can be carried out without heating.

The adjustment of the cutter is generally made by pacing copper sheets. The

proper adjustment is that it adjust cut off the film without making much nose. If

the cutter is unable to be adjusted well, is must be replaced. Adjustment of the

cutter must be carried out under heating (about 120℃).

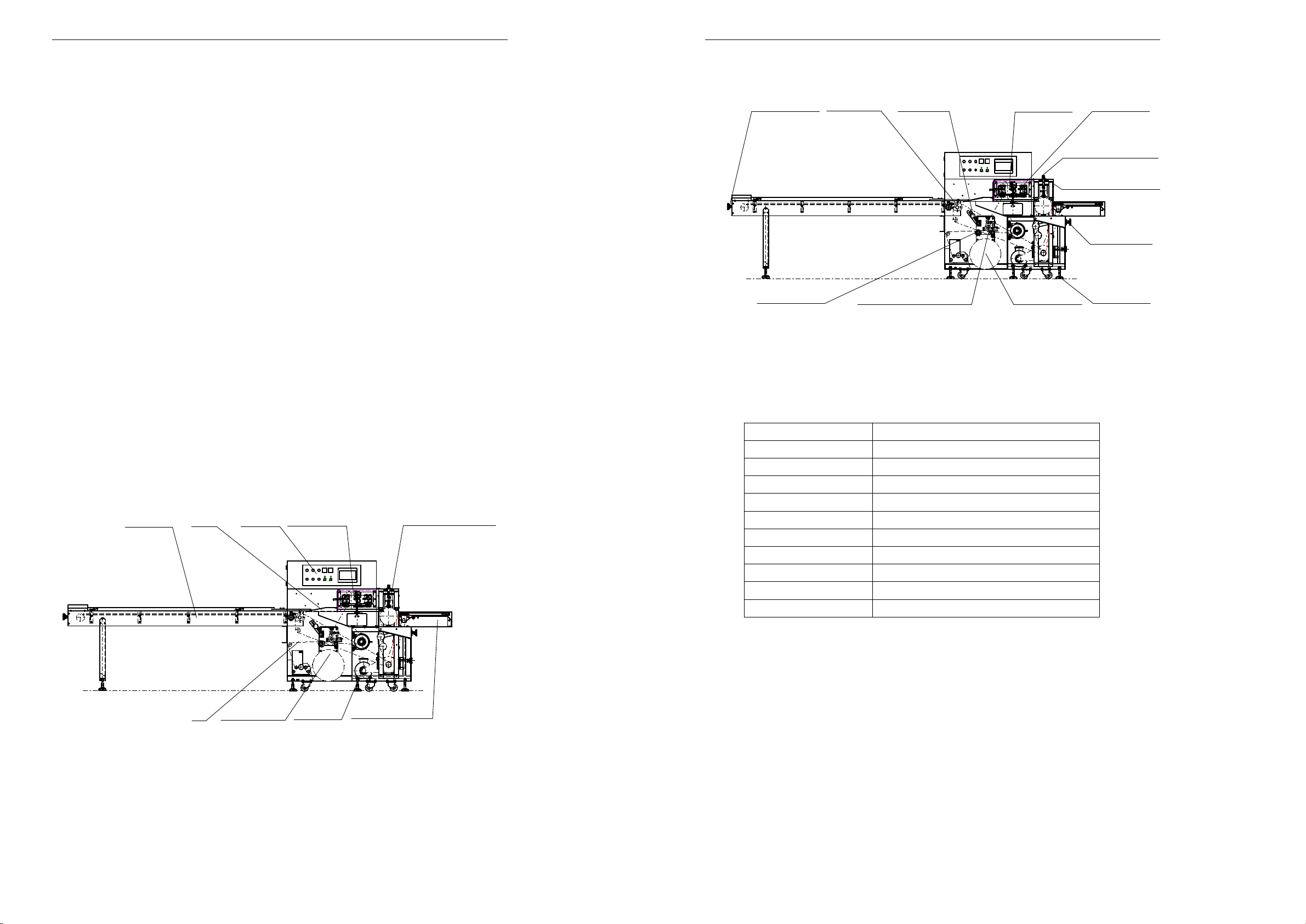

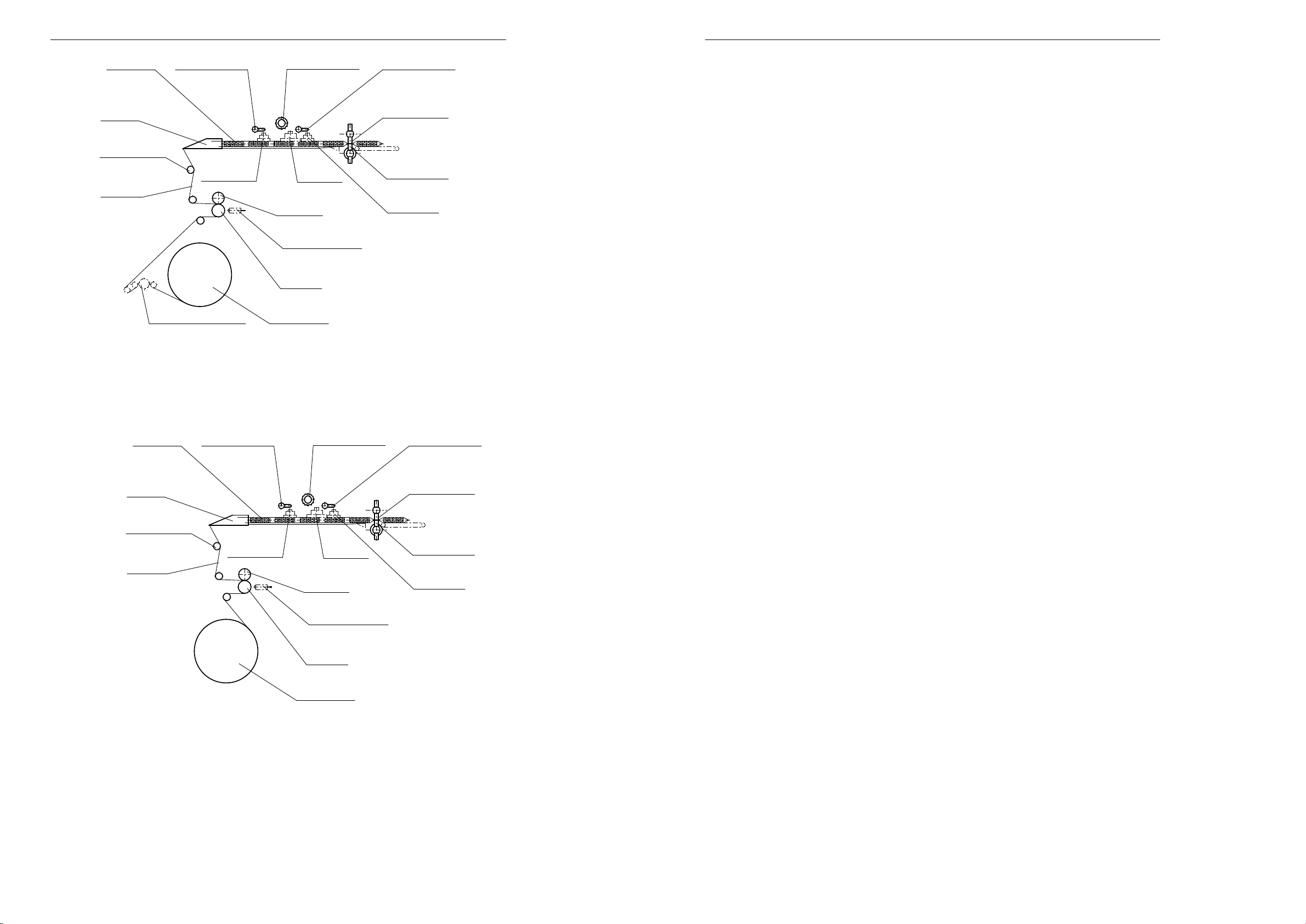

2) Adjusting the height of the end dealing knife holder

The height of the end dealing knife holder should be adjusted according to eh height

of the packed product so as to make the meshing center of the sealing knife align

with the height of the center of the packed articles, as shown in diagram 4 and 5. To

adjust, loosen the four screws of the side board of the cutter holder, then adjust the

up-and-down adjusting screw of the end sealing (the middle screw), making the

distance between the meshing position of the upper and lower sealing knives and

the working plane is about a half of the height of the packed product. After

adjustment, don’t forget to tight the four loosened screws before restart the machine

again.

3) Adjusting the end sealing knife speed

The speed of the end sealing knifes should be adjusted according to the different

lengths of the packages. The speed should be adjusted so that the linear velocity of

the end sealing knifes is equal to the speed of the packing film, there is no paper lay

up and straining paper cutting at the cutter. If there is lay up, is means the knife

speed is slow and it needs to increase the speed with the “end sealing knife

adjusting handwheel” (see diagram 2); if the paper is strained, is means the knife

speed is too high and it needs to decrease the speed with the “end sealing knife

adjusting handwheel”, until reach the synchronized speed.

4) Adjusting the cutting position of the end sealing knives

In this feeding machine, the linkage relationship between the between the push rod

and the end sealing knives is different according to the lengths of the packages. The

method and procedures for adjusting the synchronous relationship between the

between the push finger and the end sealing knives are as following:

(A) When color marks are printed on the film package:

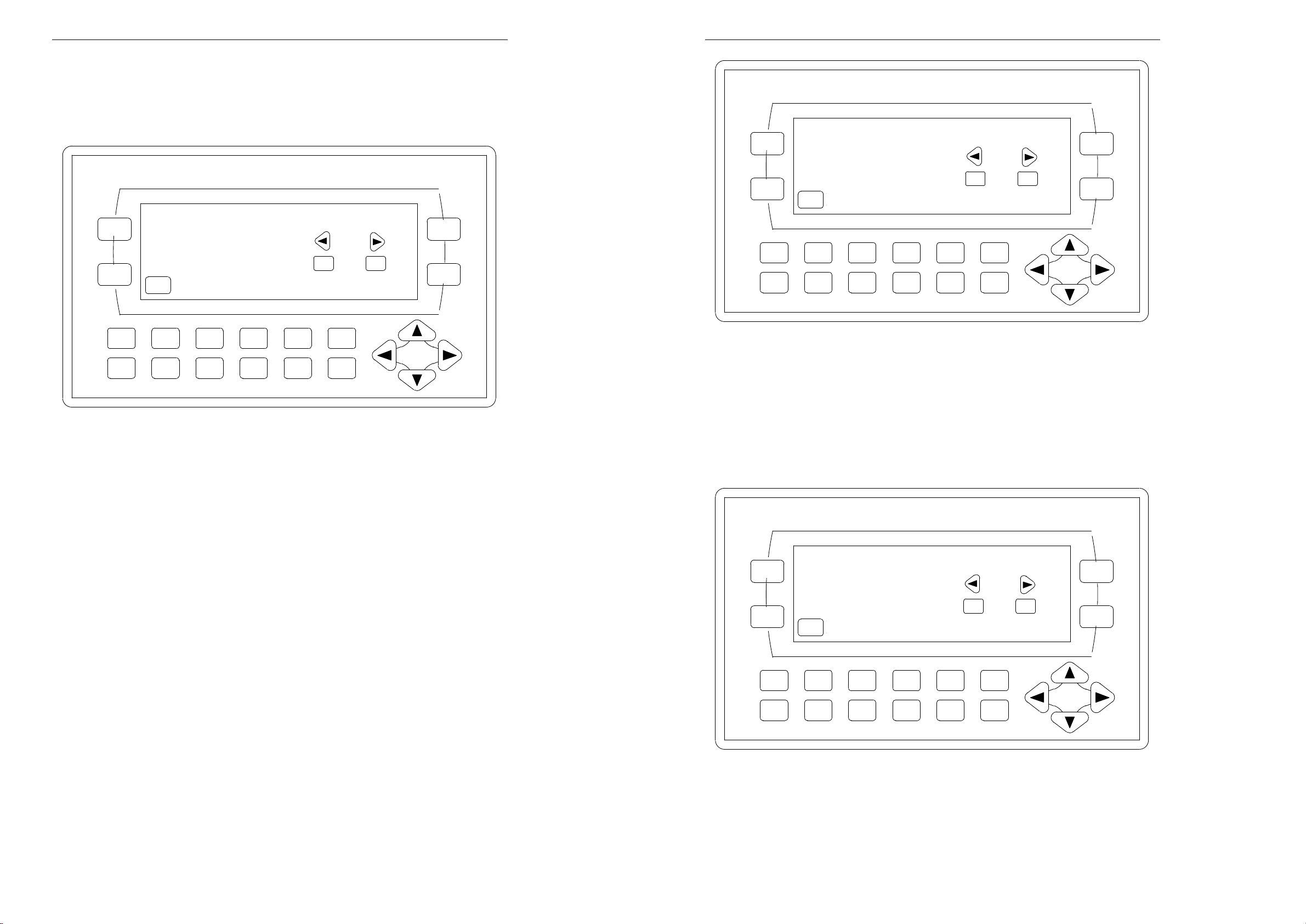

(1) When there is no product in packages, select “parameter setting” display and set

the value of the “cutting position” with the human-machine interface so as to

adjust the cutting position of the end sealing knives. (refer to section 5.1 for

setting method),set the cutting position at the color mark.

(2) Put 3 to 5 packed articles between the push fingers of the feeding mechanism,

star the machine, when the packed articles reach 100mm away from the front of

the end sealing, stop the machine.

(3) Check to see if the packed articles are between the two color marks, and

measure the deviation direction and amount and record them.

(4) Take out the packed articles, adjust the push finger position with the “finger

position adjusting handwheel” (the handwheel can be turned after it is pushed

inward), so as to adjust the position of the packed articles.

(5) Repeat steps 2 to 4, until the packed articles are just between the two color

marks.

(B)When there is no color mark on the film package:

(1) Put 3 to 5 packed articles between the push fingers of the feeding mechanism,

star the machine, when the packed articles reach 100mm away from the front of

the end sealing, stop the machine.

(2) Check visually to judge if the end sealing position is between the two packed

articles and measure the deviation direction and amount and record them.

(3) Take out the packed articles, adjust the push finger position with the “finger

position adjusting handwheel” (the handwheel can be turned after it is pushed

inward), so as to adjust the position of the packed articles.

(4) Repeat steps 1 to 3, until the packed articles are just between the two color

marks.

5. Machine operation

1) Safety check: Check and make sure there is no foreign matter on the conveyer

belt, working table, and end sealing knives, and there is no other person around

the machine.

2) Switch on the power. Open the door of the cabinet and connect the main breaker,

close the cabinet, check to see if all thermostats and power supply indicator lamp

on the control board are normal, and see if the display of the human-machine

interface is normal.

After safety check and the power supply is normal, carry out the following operation: