All Hutton products, where appropriate, come with easy to follow instructions. Please take time to read these carefully before assembling.

Hutton products are built to last with high quality timber to refined designs. Joinery standards are second to none with professional

carpenters using pressure treated softwood that offers long-lasting protection against wood decay and insect attack.

Although the Tanalith®wood preservative used in the pressure treatment process is of the highest quality, it doesn’t protect timber from

the effects of weather. Without additional protection UV rays from the sun will weather timber changing the colour to silvery grey. Moisture

will negatively affect the lifespan and performance of a timber product, so it’s essential to add a high quality protective water-repellent

coating to your Hutton product.

Here are our tips and advice for getting the best out of your product.

Softwood is a natural product that

can twist or warp through changes

in climatic conditions. To minimise this,

Hutton products should always be sited

on firm and level ground that is away from

areas where water collects.

During the pressure treatment

process, some grain may be raised. If

desired this can be removed with a little

light sanding.

Green marking may become visible

as salt leaves the timber whilst it

dries following pressure treatment. It will

fade over time and does not affect the

performance of the product. Remove any

of this solid salt residue with a wire brush

or light sanding prior to painting.

A micro-porous (breathable) coating will

allow any further moisture to evaporate

out through the paint.

Changes in the weather may cause

fixings to loosen but these can be

tightened up as appropriate.

Softwood may at times develop

cracks in the surface called ‘shakes’.

These are a natural occurrence and

can be prevalent during changes in

temperature and humidity as the timber

expands and contracts. Please note that

this will not affect the performance or

durability of your product. If desired, any

‘shakes’ can be rectified by applying a

proprietary wood glue making sure to

follow the manufacturer’s instructions at

all times. Once dry this can be sanded

to a smooth finish. Application of a high

quality protective water-repellent coating

can reduce cracking by stopping moisture

penetrating into the timber, one of the

causes of this natural process in timber

products.

Over time the colour of your Hutton

product will gradually weather, first

to a honey brown and then to a silver

grey. This does not indicate any loss

of preservative protection. To keep the

original colour of your timber you will need

to apply a clear wood paint, oil, or stain,

that has UV blockers to stop the greying

process.

A quality wood paint or oil can be

applied to your product to provide

protection and colour. Garden designs can

benefit from a coloured timber product

whether it be a bench, arch, arbour or

building, complimenting planting and

adding year-round colour. Apply in dry

weather and follow the manufacturer’s full

recommendations.

Some staining can occur on paint

coatings as tannins and/or sap/

resin come out of the new timber. This is

a natural process but a stain-blocking

primer and/or knotting agent can be

applied prior to painting to minimise

potential staining.

Pressure treated products can be

painted with a high-quality wood

treatment as long as the moisture content

is below 18%. Always check with the

manufacturer as some treatments can

cause the timber to warp or split if it

hasn’t fully dried.

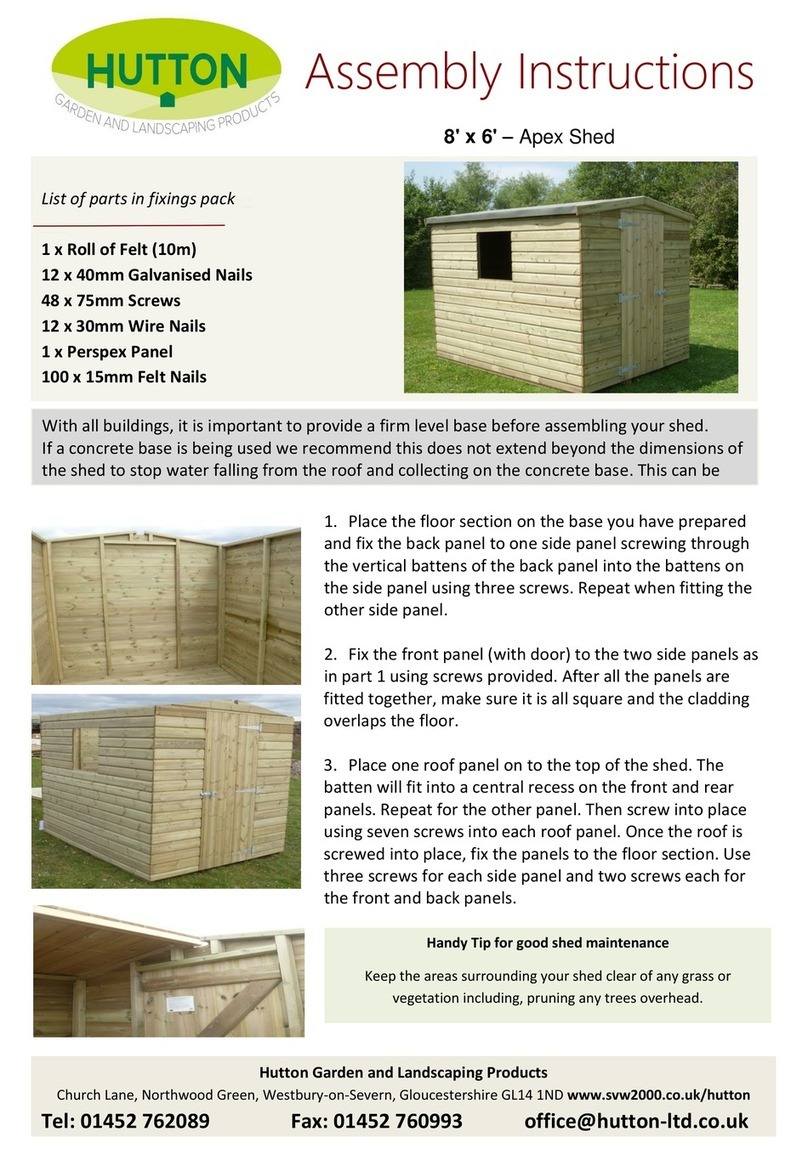

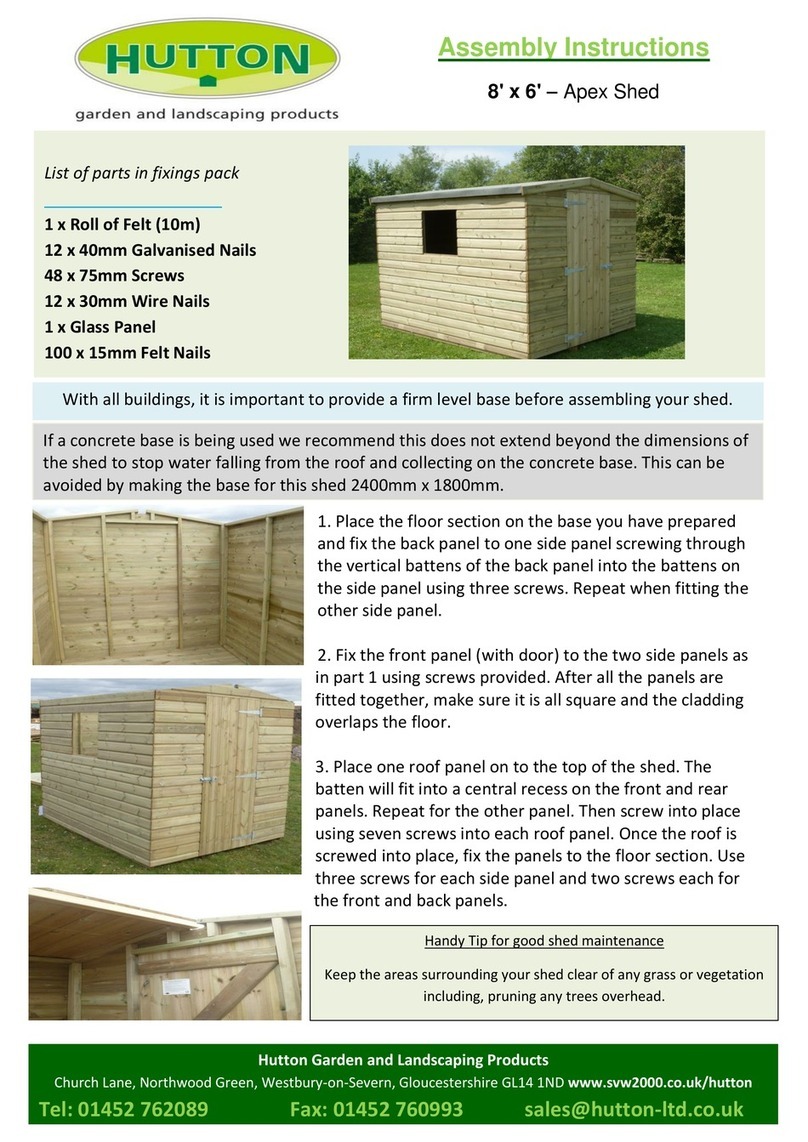

Sheds are pressure treated but will

need additional protection from

the weather and in particular, moisture

penetration. Apply a high-quality water-

repellent paint or oil to help seal the shed,

making sure that joints and fixings such

as nails and screws, are well covered. A

good microporous coating will allow any

internal moisture to evaporate out through

the external coating.

When applying a wood paint, oil, or

stain, pay particular attention to

horizontal surfaces and areas that can

collect water.

Coatings will degrade quickest on a

horizontal plane with cheaper products

wearing faster. Vertical surfaces can last

for years before a maintenance coat is

required.

Maintain your timber product on an

annual basis, or sooner if required.

Clean paint coatings with soapy water

and apply a maintenance coat when

required. The better the quality the more

years it will be before a maintenance coat

is needed. Untreated timber products

should be cleaned with soapy water or a

wood cleaner.

In the unlikely event a product is faulty

or damaged upon delivery, any issue

must be advised within a reasonable

period. The definition of reasonable

depends on the product and how obvious

the fault is, however, even with more

complex items you should work on the

basis that this is no more than three to

four weeks from receipt. This does not

affect your statutory rights.

Whilst your delivery driver is present

ensure that you check your shipment

before signing the delivery receipt, as

notifications of damages or shortages

should be noted on the signed proof of

delivery.

To view our tutorial videos on product

maintenance, please visit

www.svw2000.co.uk/you-tube-videos

www.huttongardenproducts.co.uk

Product Care