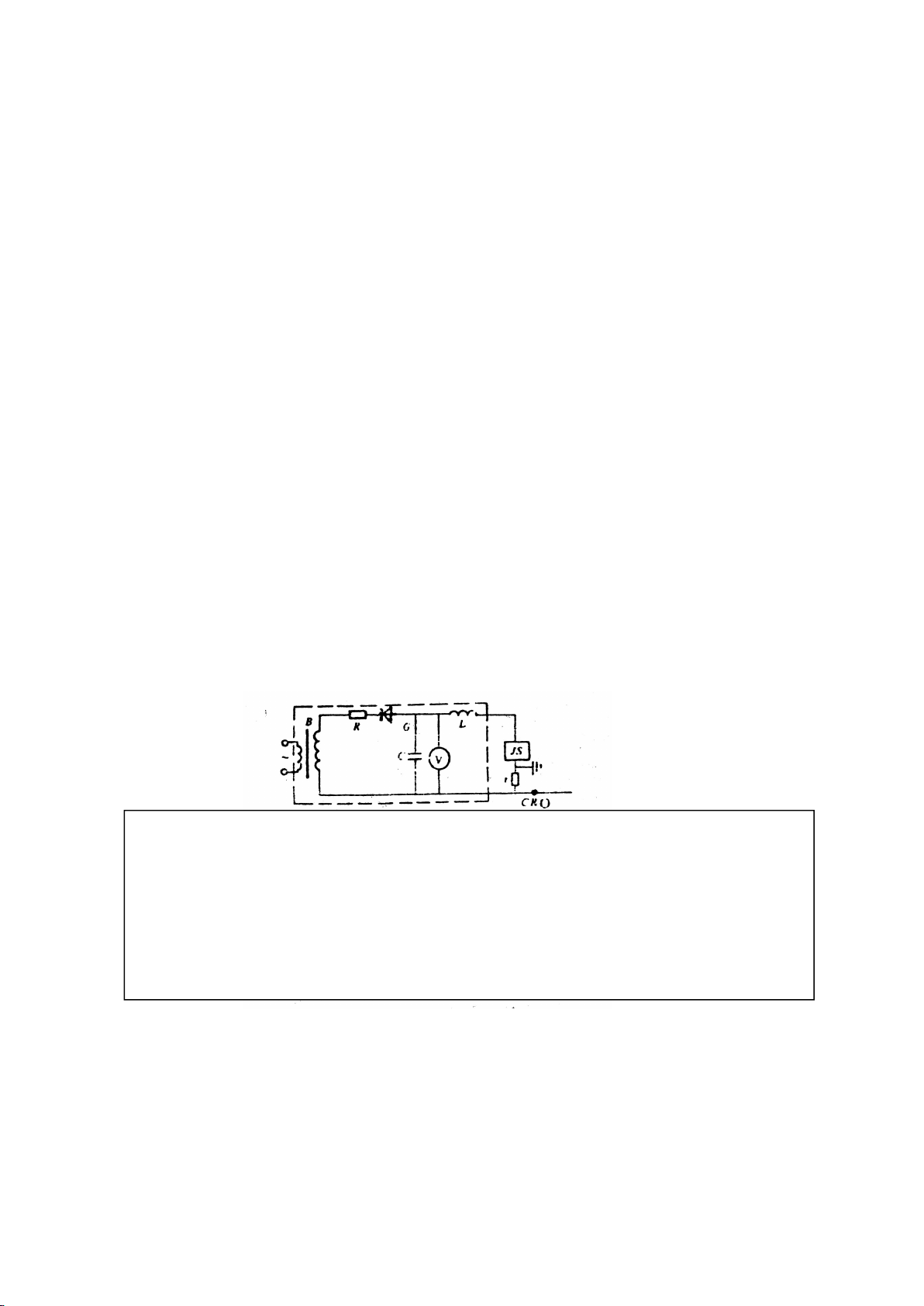

Figure 1 (b) shows circuit diagram of JS-8 type operating cycles counter, it

is rectifier type structure. When the arrester operating, voltage drop on the valve

R1 charge capacitor C through full-wave rectifier, then C discharge to L of

electromagnetic counter and let it count. For this counter, the resistance value

of valve R1 is small (when at 10kA, the voltage drop is 1.1kV), current capacity

is larger (1200A square wave), the minimum action current is 100A (8 / 20μs)

impact current. JS-8 counter is suitable for 6.0 ~ 330kV arrester, JS-8A counter

can be used for 500kV arrester.

2. Inspection method for action and principle of counter

As bad seal, may there are moisture and water will enter operating cycles

counter during operating, which will make internal components corrode, further

counter cannot work properly, so the "regulations" require that this device

should be checked one a year. The two methods of on-site inspection counter

action are: capacitor release current method (DC&AC) and standard impulse

current method. Research indicates that standard impulse current method is

more reliable; the principle circuit diagram is shown in Figure 2.

Let 8/20 μs, 100A impulse current waves generated by impulse current

generator act on operating cycles counter, if counter is functioning normally,

which indicating the instrument is well, otherwise it should be repaired. For

example, a power administration uses this method to test 27 counters, three of

them cannot act, the technician finds that the internal components are affected

Fig. 2 the principle circuit diagram for standard impulse current method

(Impulse current generator in the dashed box)

C---charging capacitor R---charging resistance L--- damped inductance

D---Silicon rectifier diode r---Current divider B---Test transformer

V---Electrostatic voltmeter CRO---high-voltage oscilloscope