6

Thank you very much for selecting our products!

For your better use of this instrument, you are kindly requested to

read this manual carefully before you use it, so as to understand its

major performances and operation method.

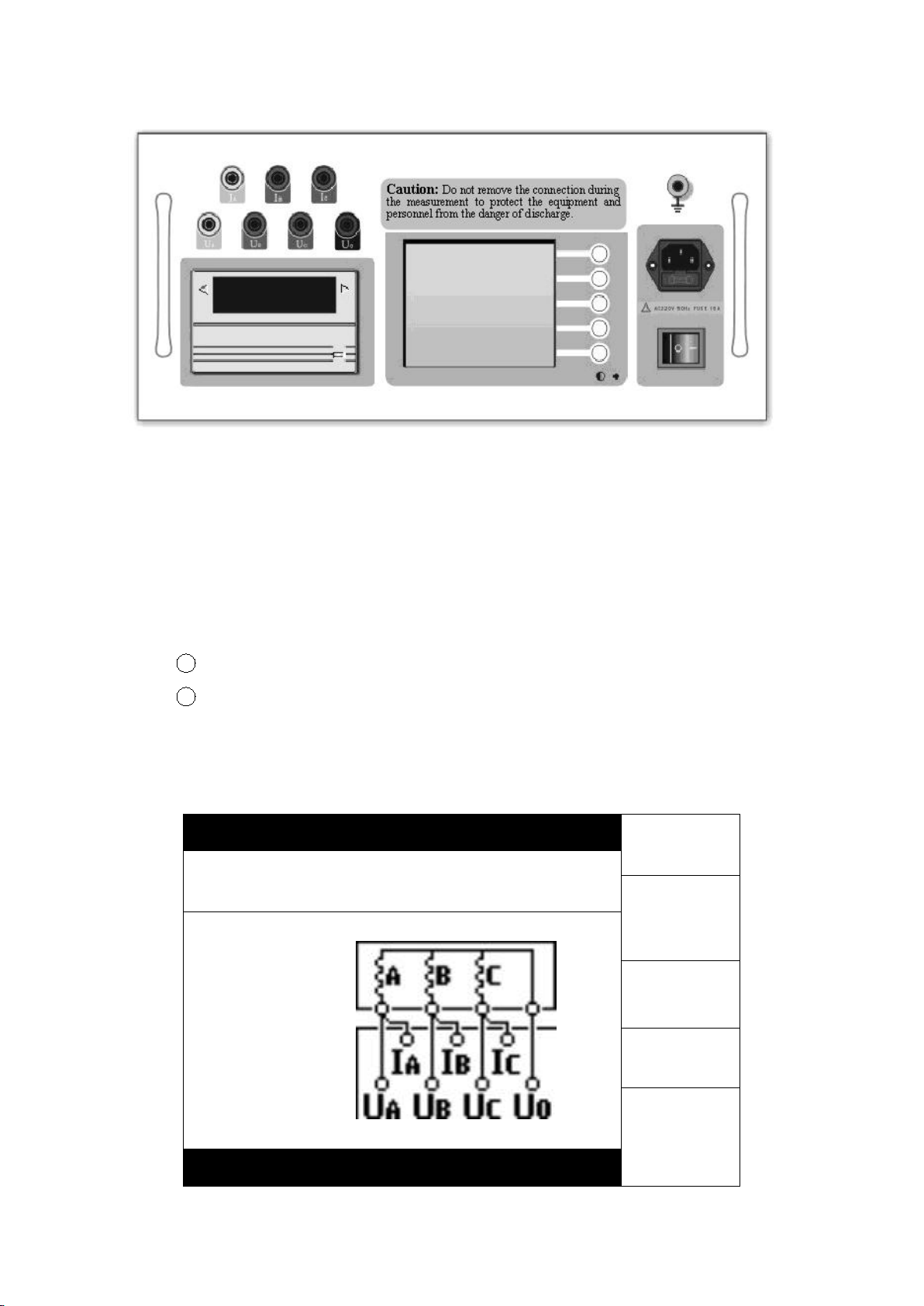

Caution:①It is not allowed to remove the wiring and directly switch off the

power supply during the measurement.

②For the no-load voltage regulating transformer, it is not allowed to

switch the tapping switch during the measurement.

③In case of a sudden power failure during the measurement, this

instrument can discharge automatically. Please do not remove

the wiring immediately. Wait for at least 30 seconds before the

connection can be removed.

④The three-phase measurement applies to the windings of YN

connection. For the windings of yn connection, since difference

exists between the three-phase and single-phase measurement

results due to the effect of the resistance of the copper bus

connected, the single-phase measurement is recommended.

⑤Caution: The three-phase measurement result doses not include

the resistance value of the neutral lead. Therefore, it is

suggested to at least verify one data using the single-phase

testing method for each phase after completing the

measurement of three-phase resistance value, so as to

determine if the neutral lead is normal.

I. General

This fast DC resistance tester (hereinafter referred to as DC resistance

tester) is the product of the latest generation for measuring the DC resistance

of transformer and is optimally designed for measuring the DC resistance of

the three-phase winding of the large-capacity transformer. It can measure the

DC resistance of the three-phase winding at the same time. In case of the

on-load voltage regulating transformer, it is not required to discharge but to

directly adjust the tapping switch. The measurement time is one third of the

traditional single-phase measurement, greatly shortening the working time and

labor intensity. As the DC resistor tester is provided with large-screen LCD and

the graphical interfaces in Chinese, the operation is visual, clear and easy.