✆

01268 205 121

| www. hydraev.co.uk | sales@hydraev.co.uk

2

CONTENTS

SAFETY ....................................................................................................................................................................................3

INTRODUCTION......................................................................................................................................................................6

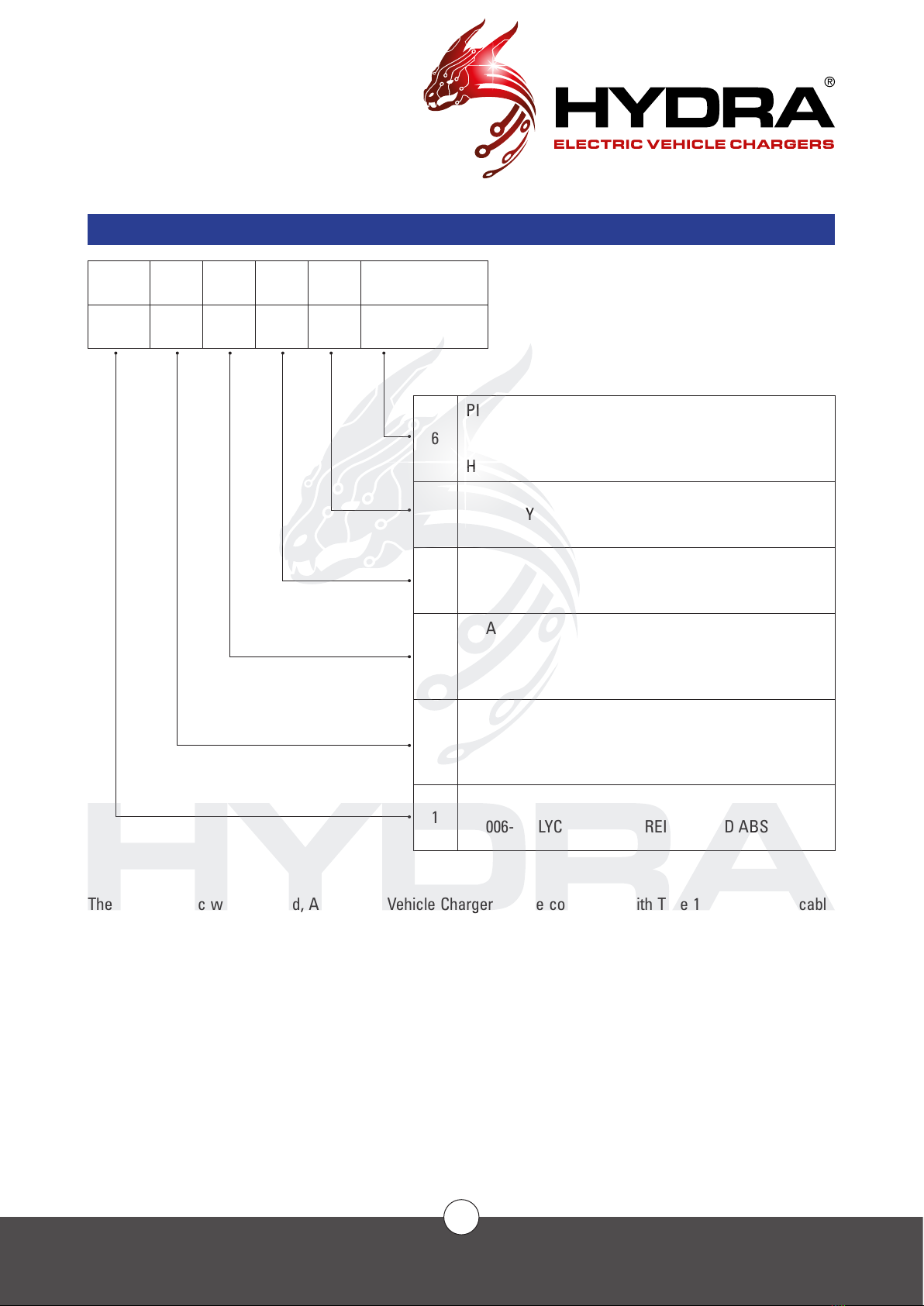

Serial Number Identication..........................................................................................................................................6

Appearance and Dimensions.........................................................................................................................................7

Technical Specications.................................................................................................................................................8

Product Features..............................................................................................................................................................9

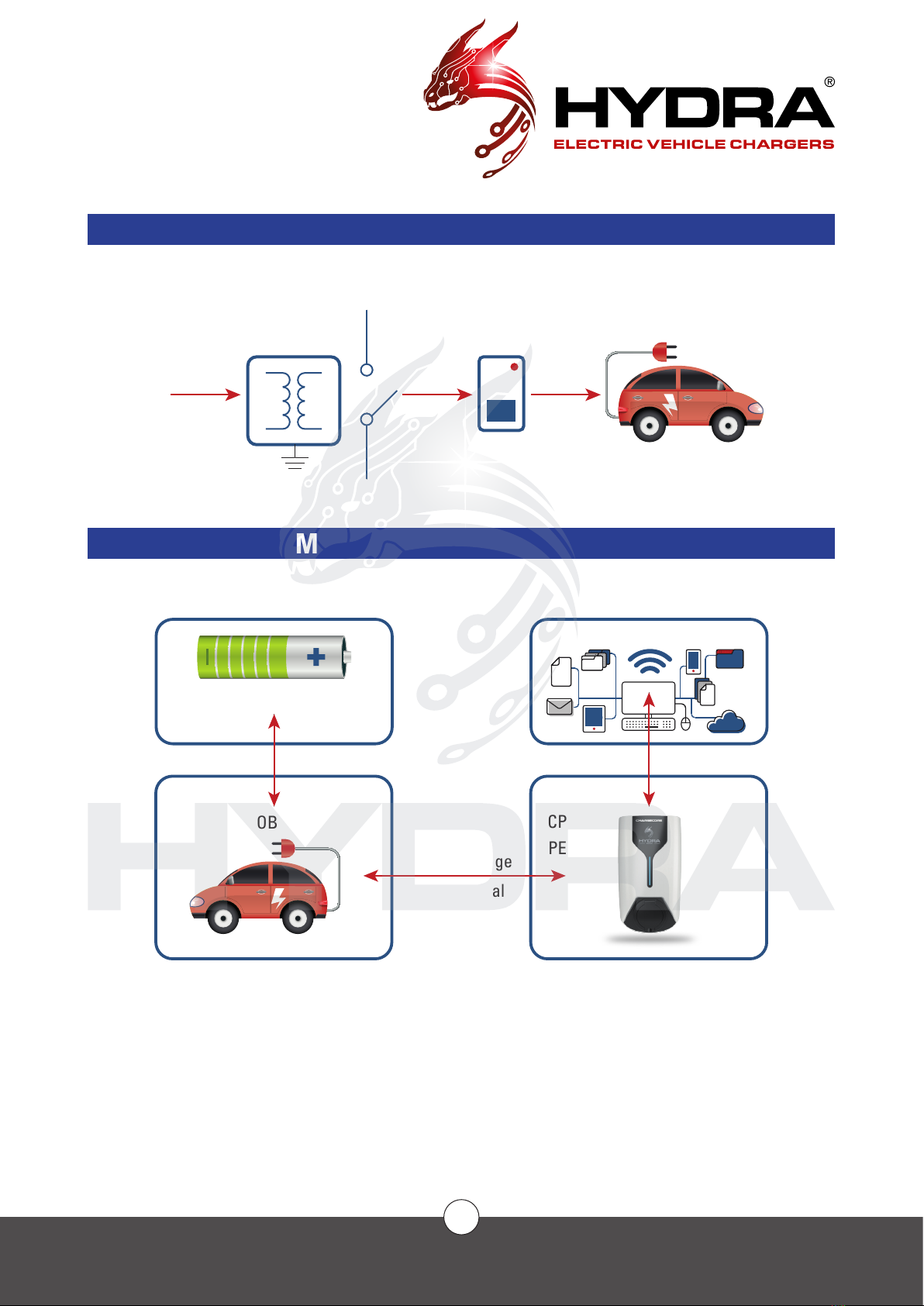

SYSTEM ARCHITECTURE ...................................................................................................................................................10

Electric.............................................................................................................................................................................10

Internal System Communications ...............................................................................................................................10

INSTALLATION .....................................................................................................................................................................11

Procedure........................................................................................................................................................................11

Site Space Requirements .............................................................................................................................................12

Mounting Requirements ...............................................................................................................................................13

Electrical Requirements................................................................................................................................................14

Network Connectivity Requirements..........................................................................................................................15

Tool Preparation .............................................................................................................................................................16

Installation Instructions - Using Quick-Connect Fly Lead.......................................................................................17

Connecting the Power Cable .......................................................................................................................................18

Installation Instructions - Without using Quick-Connect Fly Lead (please read important notice).................17

COMMISSIONING ...............................................................................................................................................................21

Power On Process .........................................................................................................................................................21

Charging Operation........................................................................................................................................................21

Emergency Operation....................................................................................................................................................21

Forced Unplugging and Recovery...............................................................................................................................21

Charging Operation........................................................................................................................................................22

Check before commissioning.......................................................................................................................................23

AFTER-SALES MAINTENANCE .........................................................................................................................................24

After Sales Service........................................................................................................................................................24

Disclaimer .......................................................................................................................................................................24

Maintenance...................................................................................................................................................................24

PROCEDURES .......................................................................................................................................................................26

APPENDIX.............................................................................................................................................................................27

LED indicator status identication ..............................................................................................................................27

Fault diagnostics (cause and resolution)...................................................................................................................27

Restriction of Hazardous Substances1 ......................................................................................................................28

Authentication ................................................................................................................................................................29