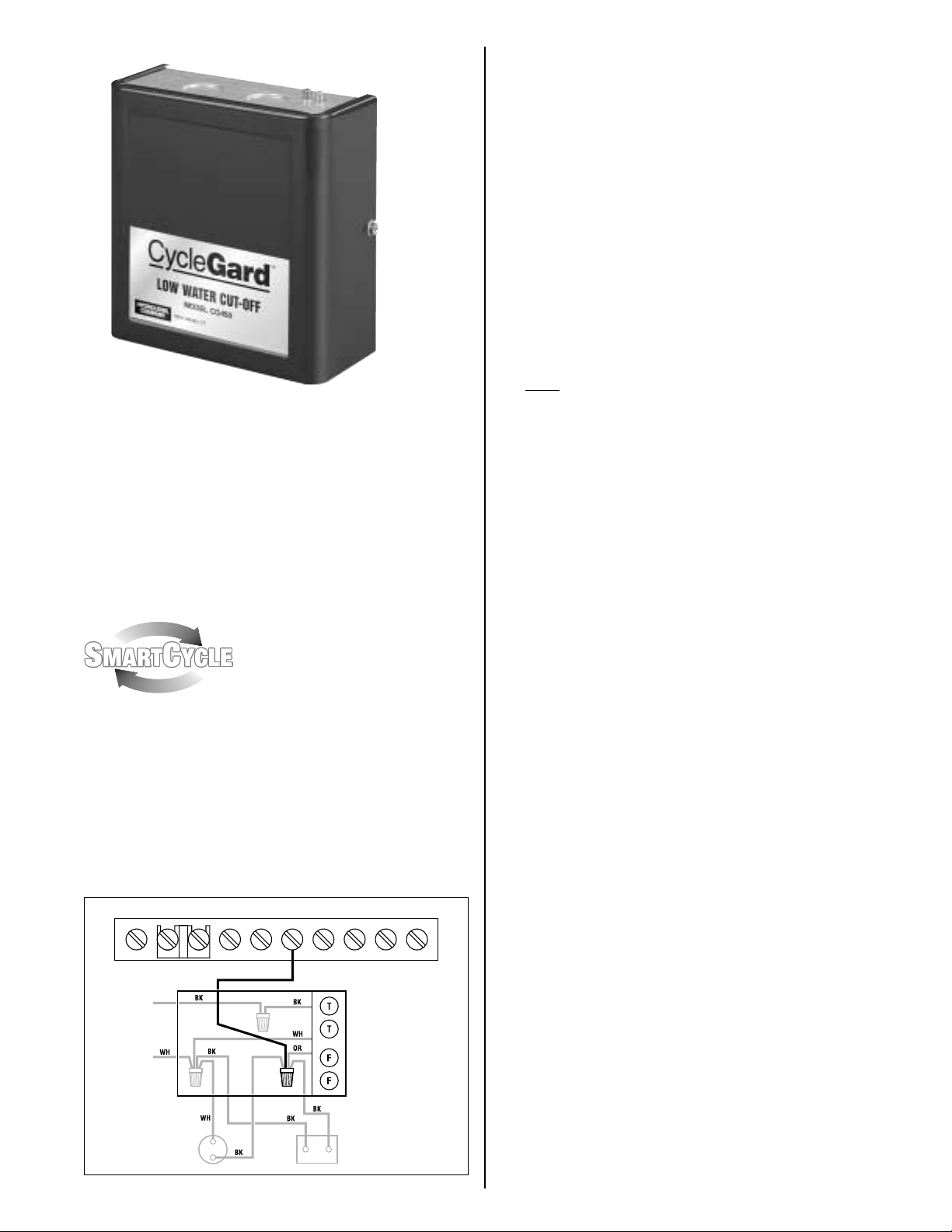

The Safgard VXT water feeder (available sepa-

rately) is fully programmable to accommodate

any steam system. By simply arranging a series

of rocker switches the delay time before feed

can be adjusted to allow condensate to return to

the boiler. Settings from 30 seconds to ten min-

utes are available. The amount of feed can also

be set from one to five gallons. If necessary, a

second delay/feed cycle is permitted. If the low

water condition still exists after the second cycle

the control will lock-out to prevent flooding of

the system.

VXT WATER FEEDER

PROBES

Test Pressure: 1000 PSI, All Models

THE PROBE MAKES THE DIFFERENCE

The probe used in all Hydrolevel controls offers

you distinctive advantages. Unlike float devices,

there are no moving parts to wear stick, or

“hang-up” the in harsh boiler environment .

A stuck or “hung-up” float can cause dangerous

low water conditions. And if suddenly released, a

float can feed cold water into overheated tubes

or plates and cause explosive results.

The Hydrolevel control has no float bowl so sed-

iment cannot collect. The reliable solid state cir-

cuitry and low maintenance probe are designed

to provide years of troublefree operation.

MAXIMUM PRESSURE: 15 PSI

INPUT VOLTAGE: 120 VAC, 60 HZ

SWITCH RATINGS: 5.8 FLA, 34.8 LRA

SWITCH CONTACTS: SPDT

ALARM CIRCUIT: 125 VA @ 120 VAC

Pilot Duty

EL1214 – STANDARD MODEL – 3/4" NPT

For 1/2”, order Model No. EL-1220 EL1214-P – 3/4" NPT

LIMITED MANUFACTURER’S WARRANTY

We warrant products manufactured by

Hydrolevel Company to be free from defects in

material and workmanship for a period of two

years from the date of manufacture or one year

from the date of installation, whichever occurs

first. In the event of any claim under this warran-

ty or otherwise with respect to our products

which is made within such period, we will, at our

option, repair or replace such products or refund

the purchase price paid to us by you for such

products. In no event shall Hydrolevel Company

be liable for any other loss or damage, whether

direct, indirect, incidental or consequential. This

warranty is your EXCLUSIVE remedy and shall be

IN PLACE OF any other warranty or guarantee,

express or implied, including, without limitation,

any warranty of MERCHANTABILITY or fitness

for a particular purpose. This warranty may not

be assigned or transferred and any unauthorized

transfer or assignment thereof shall be void and

of no force or effect.

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

FAX: (203) 773-1019