OPERATING TEST PROCEDURE

1. Aft r installation, bring th boil r wat r to

a saf op rating l v l, turn on pow r and

s t th th rmostat to call for h at. Th

amb r LED lamp should b off. T e boiler

will fire immediately.

2. Slowlylow r th boil r wat r to a point

b low th prob . Th amb r LED lamp on

th control will light. Th lamp may b gin

to flick r with th bouncing wat r l v l.

Stop draining th boil r wh n th lamp

glows st adily. NOTE: Th wat r should

not b low r d b yond a visibl point in

th gaug glass.

3. Th boil r will shut down within 15

s conds.

TEST BUTTON

Th CG470 is quipp d with a button to t st

wiring and control op ration. To us th t st

button, r mov th cov r and pr ss th but-

ton locat d on th circuit board. Th burn r

will shut off for th l ngth of tim th button

is pr ss d. If th burn r do s not shut off,

r mov pow r and r ch ck wiring. Not :

Hydrol v l r comm nds low ring th wat r

l v l (as d scrib d in “Op rating T st

Proc dur ”) to functionally t st th control

and prob op ration on an annual basis.

IF BURNER DOES NOT SHUT DOWN IN

LOW WATER

1. Ch ck t rminal block wiring to insur that

all conn ctions ar corr ct.

2. Ch ck th prob installation to insur that

th r is 1/4" cl aranc from any surfac

within th boil r or pip . (R f r to St p 1

on pag 1 of this instruction sh t.

3. Cl an th boil r in accordanc with th

manufactur r’s instructions. Machining

oils, gr as , rust and oth r contaminants

in th boil r wat r can caus foaming or

surging and mak a low wat r condition

difficult to d t ct during burn r op ration.

IF THE AMBER LED LAMP IS ON

Th amb r LED lamp indicat s that th wat r

is b low th prob . If th gaug glass shows

that th wat r is at th corr ct op rating l v l

and th amb r LED is lit, ch ck th following:

1. Ch ck for plugg d gaug glass.

2. Mak sur prob l ad wir is prop rly

s cur d to th t rminal.

3. Ch ck for prop r ground b tw n prob

and boil r sh ll. Exc ssiv us of T flon

tap or s aling compound may isolat th

prob from th boil r sh ll.

4. R mov prob and xamin for oily

r sidu . Cl an prob with st l wool and

skim boil r.

IF THE RED LED LAMP IS ON

Th r d LED lamp indicat s that th boil r

has xp ri nc d an unsaf t mp ratur

(250°F). Th control will lock out th burn r

circuit and illuminat th LED wh n this

occurs. DANGER: Adding wat r to an ov r-

h at d boil r can caus an xplosion. Th

boil r must b allow d to fully cool b for

adding wat r. Th boil r should b valuat d

by a qualifi d s rvic t chnician b for

r storing op ration. Th Cycl Gard control

should b r plac d.

IF THE RED LED LAMP IS BLINKING

A blinking r d LED lamp indicat s that th

control has b n lock d out on an unsaf

t mp ratur at som point in its history. Th

Cycl Gard control should b r plac d.

IF THE GREEN LED LAMP IS ON

Th gr n LED lamp indicat s that th control

is conducting an Int rmitt nt L v l T st. Th

burn r do s not fir during th t st p riod.

S Int rmitt nt L v l T st F atur on this

pag for mor d tails.

Enhanced Intermittent

Level Test Feature

To provid add d prot ction to today’s small-

r boil rs, Cycl Gard Mod l CG470 is

quipp d with an nhanc d Int rmitt nt L v l

T st (ILT) f atur . Fift n minut s aft r th

boil r r ach s boiling t mp ratur , th ILT

f atur r mov s pow r from th burn r for

60 s conds. During this ILT t st, foam dissi-

pat s and th wat r l v l quickly stabiliz s,

allowing th CG470 to monitor th tru wat r

l v l in th boil r. If th wat r in th boil r is

at a saf l v l, th control will r - n rgiz th

burn r. If th wat r l v l has dropp d to a

l v l b low th prob , th control will k p

th burn r off (and s nd pow r to an optional

wat r f d r) until th wat r l v l is r pl n-

ish d. Th 60 s cond ILT t st will r p at

v ry 15 minut s as long as th boil r

r mains at boiling t mp ratur . Th ILT f a-

tur dis ngag s wh n th boil r t mp ratur

is b low th boiling point.

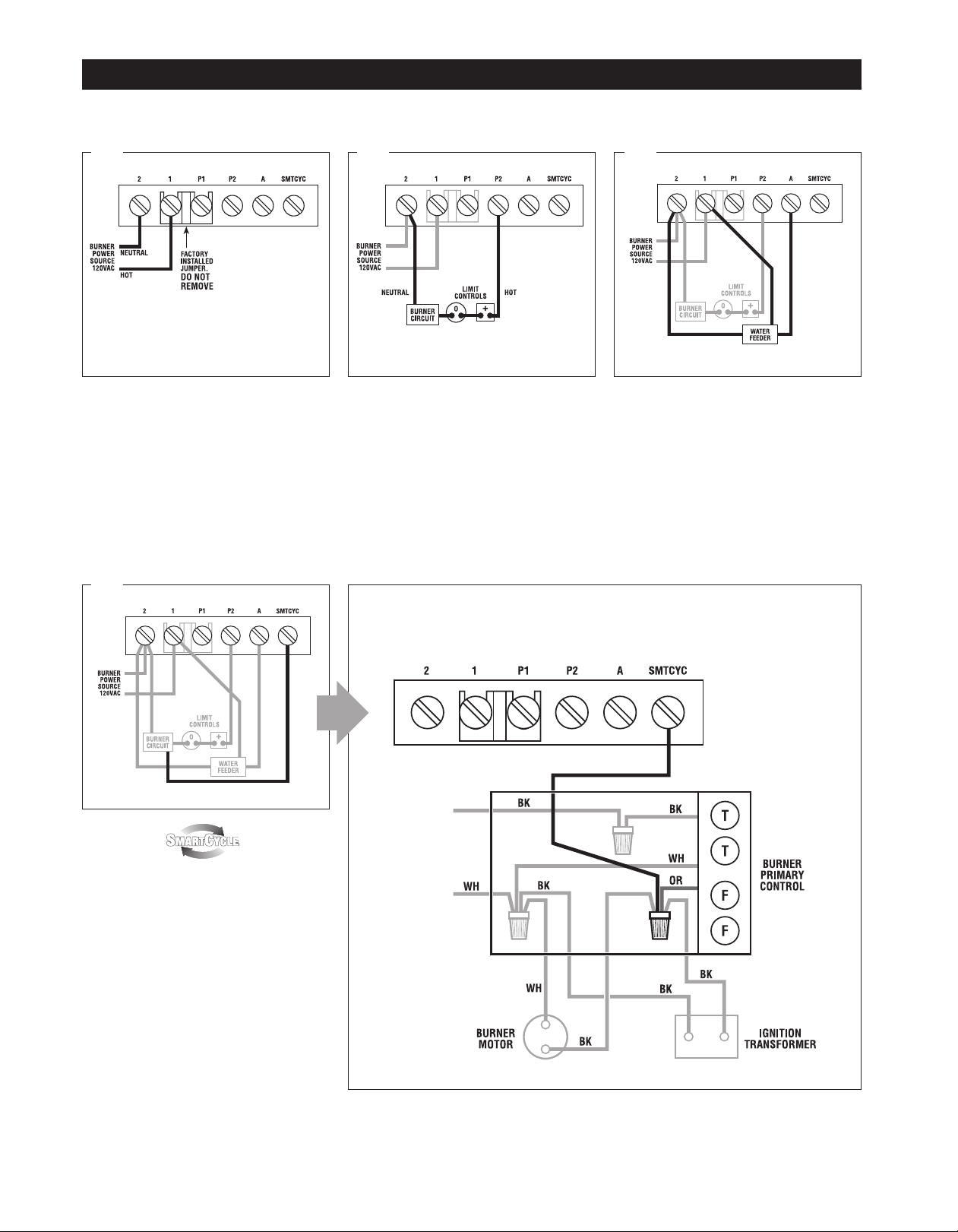

Th optional Smart Cycl f atur is d sign d to

pr v nt unn c ssary ILT t sts in th v nt th

burn r cycl s off for oth r r asons ( x. pr s-

sur limit or th rmostat calls). Wh n activat d

(s wiring on pr vious pag ), th Smart Cycl

f atur r starts th 15 minut timing s qu nc

ach tim th burn r fir s. So, for xampl , if

th pr ssur control shuts down th burn r,

th Smart Cycl f atur will r s t th 15

minut clock onc th pr ssur control r -

n rgiz s th burn r. This pr v nts an ILT

from occurring soon r than is n d d as th

control was abl to monitor th s ttl d wat r

l v l during th pr ssur limit int rruption.

Hi Temp Lock-Out

Unlik any oth r st am low wat r cut-off, th

CG470 monitors boil r t mp ratur in addi-

tion to wat r l v l. This f atur will shut

down and lock out th burn r circuit if th

boil r r ach s an unsaf l v l (250°F).

3

OPERATING INSTRUCTIONS

NOTE: For prop r low wat r cut-off op ration, th boil r should b cl an d at initial installation and p riodically th r aft r. R f r to th boil r

manufactur r’s instructions for cl aning proc dur s.