Trouble Shooting your Combination Softener Unit

Problem: ishy or unpleasant odour is apparent in the treated water that is not present in the untreated water.

1. pH of the incoming water may be high. • This odo r may be apparent on start p and will

typically be red ced or eliminated after a co ple

service r ns and regenerations cycles of the

Combination Softener nit.

2. pH of the incoming water maybe high in

combination with chlorine present for

disinfection.

• The addition of chlorine along with high pH

typically increases the chances that an odo r will

be present in the treated water With the presence

of chlorine, it is nlikely odo r will be eliminated.

Chlorine can be removed thro gh the se of an

activated carbon filter, however it is highly

recommended that additional disinfection methods

be re-employed downstream of the Combination

Softener nit with Ultraviolet Sterilizers or

Chlorination P mps.

Problem: Combination Softener unit was removing colour from water, but then starts to show colour again

until regeneration. Then colour is removed again.

1. Capacity of Combination Softener nit is being over r n

and res lting in tannins not being removed near the end

of service r n.

• Decrease the gallons between service r ns to a

point where no colo red water is appearing

between one regeneration to the next.

Problem: Combination Softener unit was removing colour from water, but then starts to show colour earlier

and earlier into service run.

OR

Problem: Combination Softener unit was removing colour from water, but no longer seems to be effective.

1. Regeneration is not being performed adeq ately. • Check to see if salt is in brine tank. If no salt is

present, last regeneration(s) may have been done

witho t salt brine. Add salt to brine tank and

man ally regenerate Combination Softener nit ntil

after allowing brine to dil te in water for at least 4

ho rs.

• Check to see if brine tank is being refilled with

water properly at the end of the regeneration

cycle and/or if water is being drawn into the valve

d ring the brine draw cycle. Injector & Screen or

Brine Valve may be pl gged and req ire cleaning.

• Check to see that valve settings are correct.

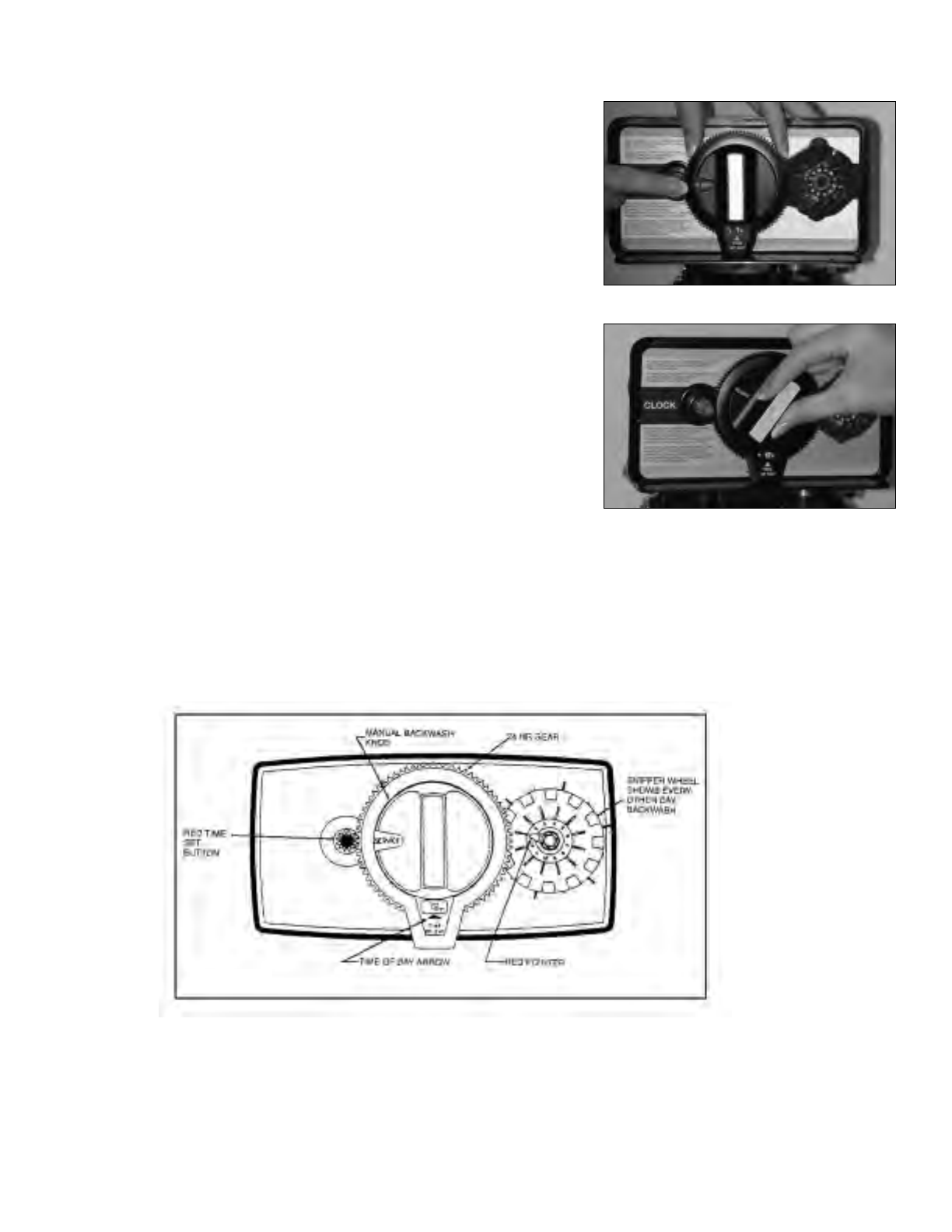

2. Regeneration is not being performed at all. • Check gallonage setting between regenerations.

Capacity set may be too large.

• Check to see that meter is t rning and properly

connected via the meter cable to the timer.

• Check to ens re that Bypass Valve is not open

and bypassing the Combination Softener nit with

ntreated water.

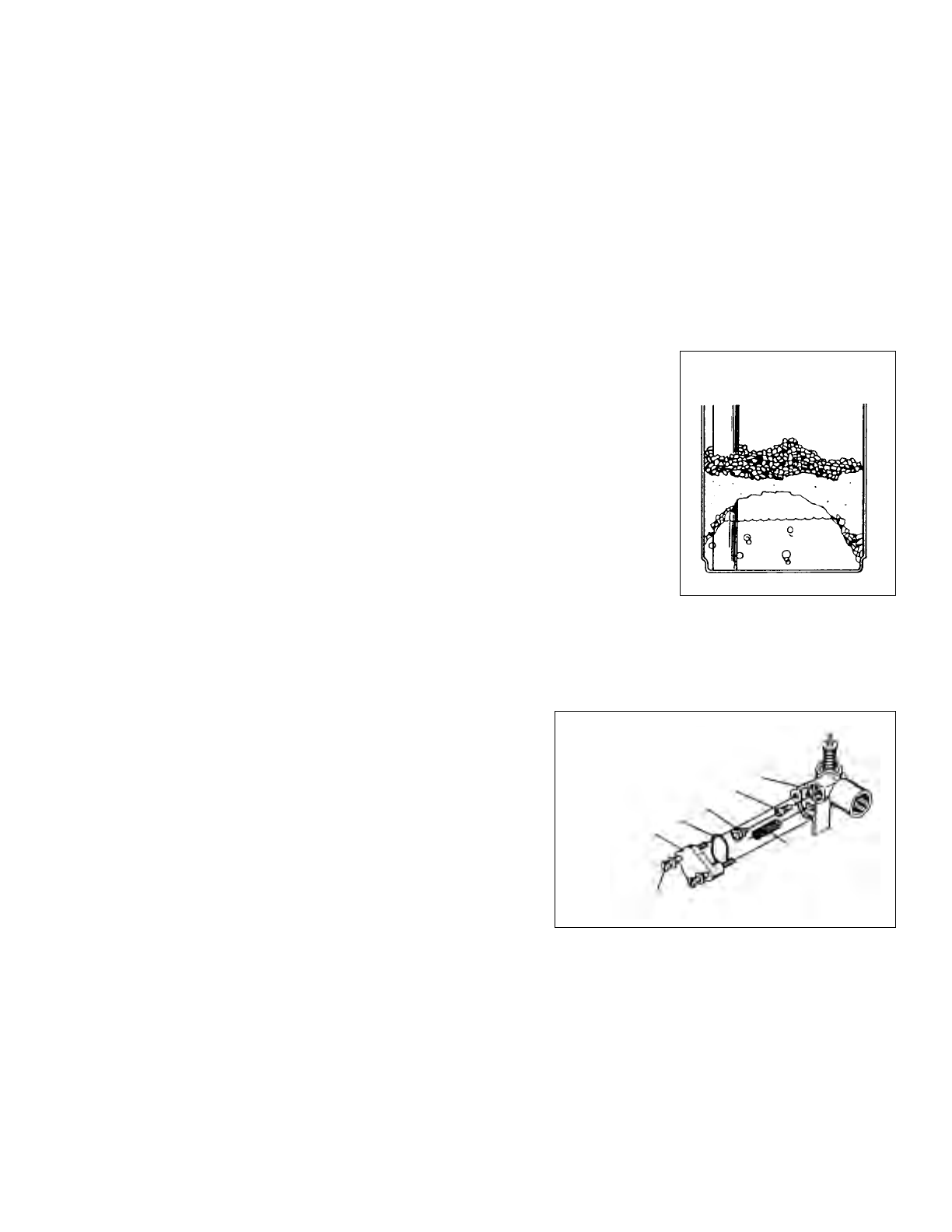

3. Resin Media may be backwashing to drain. • Confirm backwash flow control is installed on drain

line and check that backwash flow control has not

been swapped for service line flow control.

• Monitor drain line d ring regeneration cycle and

check that no resin beads are exiting the

Combination Softener nit.

4. Combination Softener nit resin media may be fo led

with organics. Check resin vis ally to confirm.

• Try man ally regenerating Combination Softener

nit two or three times in a row. Allowing

approximately fo r (4) ho rs between regenerations

to allow salt brine to be sat rated.

7