Installation Instructions

All government codes and regulations governing the installation of these devices must be observed.

CAUTION: If the ground from the e ectrica pane or

breaker box to the water meter or underground copper pipe

is tied to the copper water ines and these ines are cut

during insta ation of the Nory bypass va ve and/or po y

pipe, an approved grounding strap must be used between

the two ines that have been cut in order to maintain

continuity. The ength of the grounding strap wi depend

upon the number of units being insta ed and/or the amount

of copper pipe being rep aced with po y. See Figure 1.

In a cases where meta pipe was origina y used and is

ater interrupted by po y pipe or the Nory bypass va ve as

in Figure 1 or by physica separation as in Figure 2, an

approved ground c amp with no ess than #6

copper conductor

must be used for continuity,

to maintain proper meta ic pipe

bonding.

Check your oca e ectrica code for the correct c amp and

cab e size.

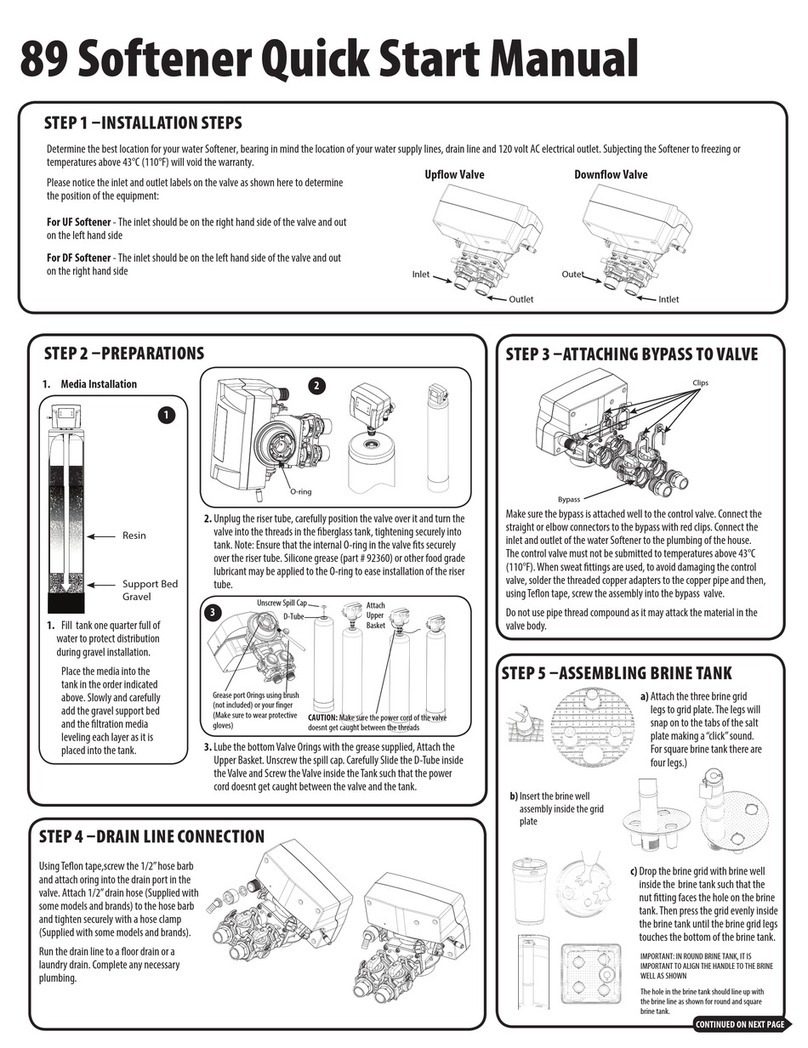

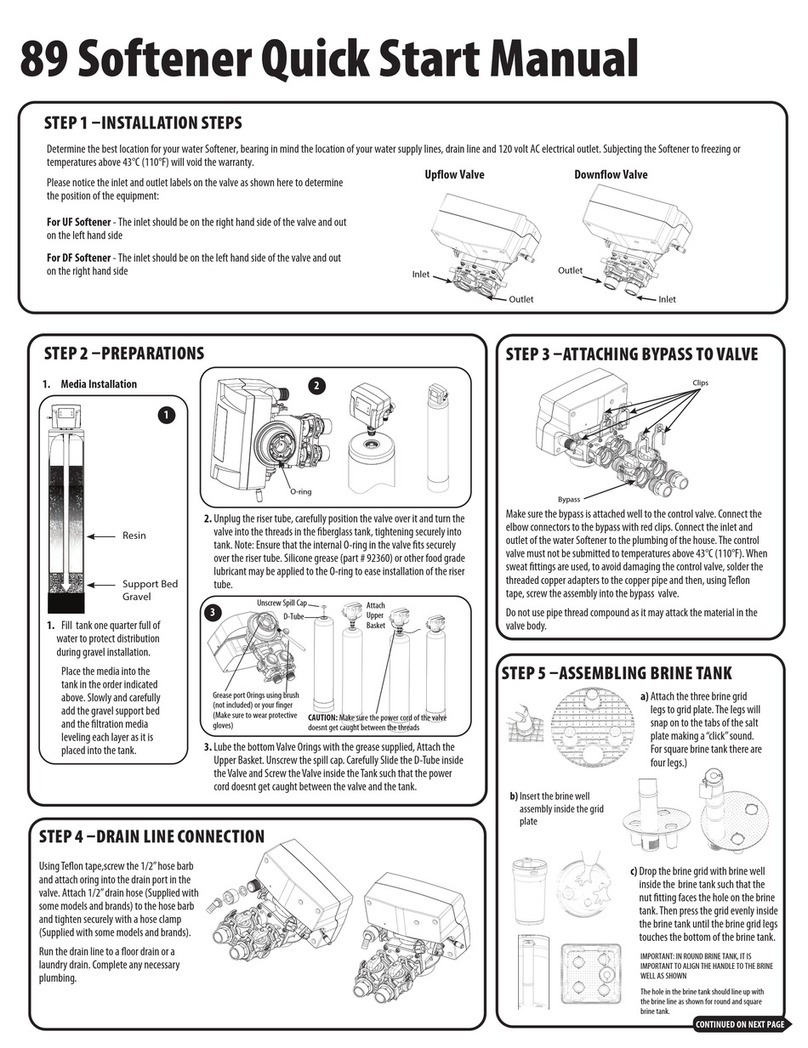

1. Determine the best ocation for your water softener,

bearing in mind the ocation of your water supp y ines,

drain ine and 120 vo t AC e ectrica out et. Subjecting the

softener to freezing or temperatures above 110°F (43°C)

wi void the warranty.

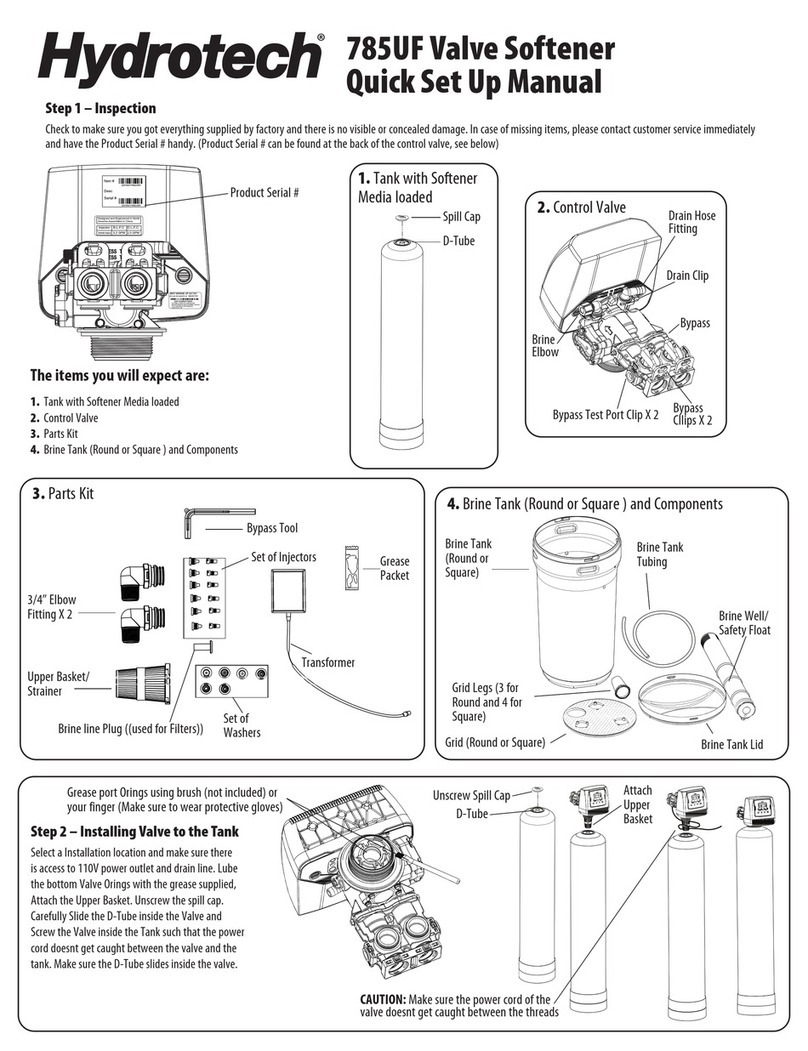

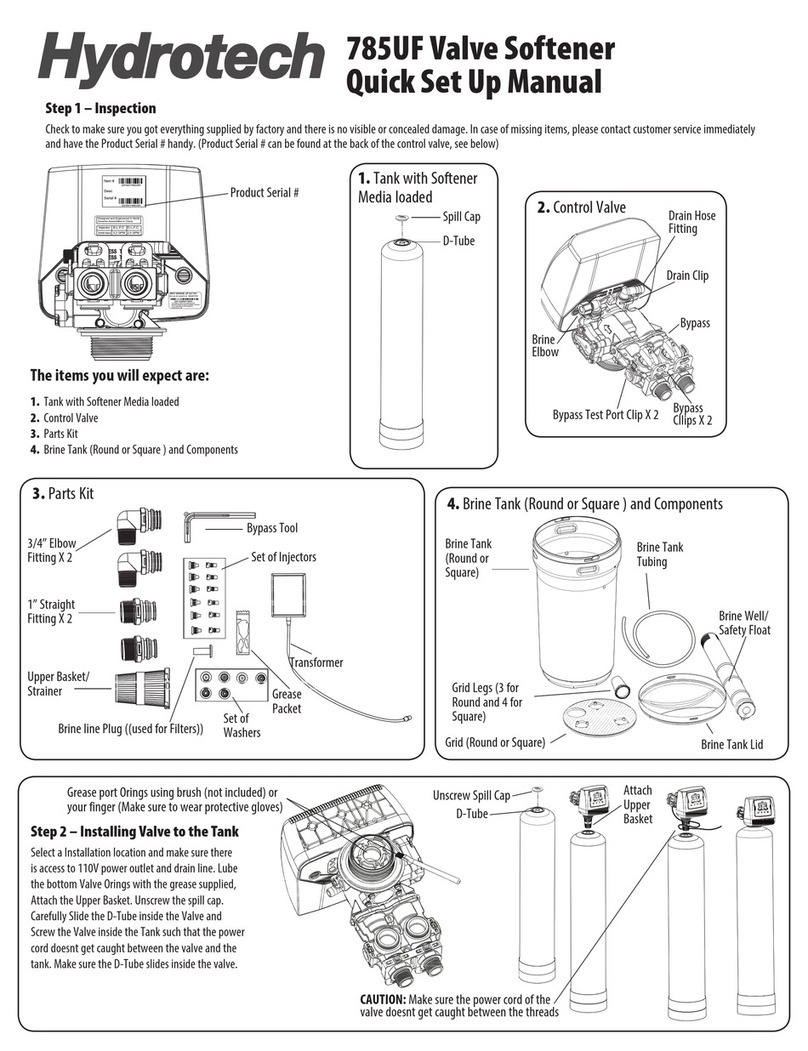

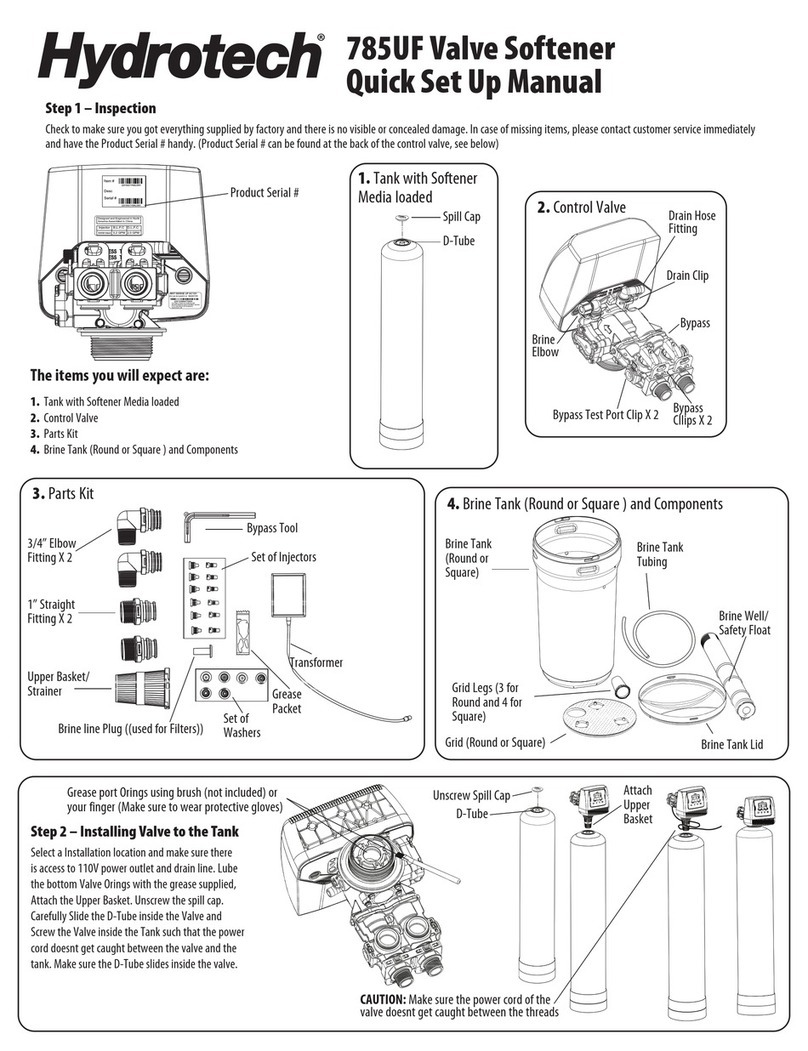

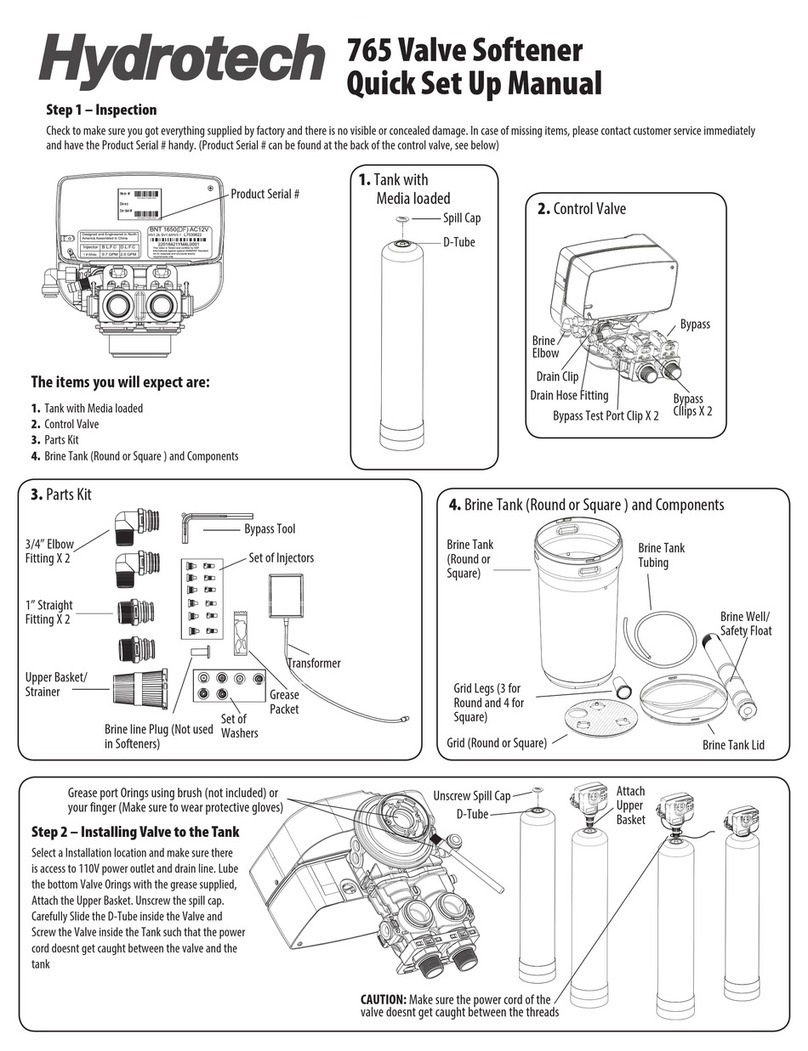

Media Installation (When Necessary)

• Remove the va ve from the minera tank.

• Temporari y p ug the open end of the riser tube to ensure that no resin or grave fa s down into the distribution.

• Fi minera tank one quarter fu of water to protect distribution during grave insta ation.

• S ow y and carefu y add the grave support bed and the softener or fi tration media eve ing each ayer as it is p aced

into the tank.

• Unp ug the riser tube, carefu y position the va ve over it and turn the va ve into the threads in the fiberg ass tank,

tightening secure y into tank. Note: Ensure that the interna O-ring in the va ve fits secure y over the riser tube.

Si icone grease (#13691) or other food grade ubricant may be app ied to the O-ring to ease insta ation of the riser

tube. DO NOT use petro eum based ubricants as they wi cause swe ing of O-ring sea s.

• The softener or fi ter is now charged with softening resin.

• It is recommended that the softener or fi ter tank now be comp ete y fi ed with water (SLOWLY) to soak the resin or

fi tration media before startup. This wi a ow the media to absorb water as we as he p disp ace any trapped air.

This wi reduce the chance of backwashing resin or fi ter media out of the tank during the initia backwash on

startup.

2. Outside faucets used to water awns and gardens shou d not supp y softened water. A new water ine is often

required to be connected to supp y hard water to the in et of the water softener and to the outside faucets. Cut the

water ine between where it enters the house and before any ines that branch off to feed the hot water heater or

other fixtures in the house and as near the desired ocation of the water softener as possib e. Insta a tee fitting on

the feed end of the cut pipe, and an e bow fitting on the other end. Insta piping from the tee to the in et of the water

softener and from the e bow to the out et of the softener. To sever the water ines which branch off to feed any

outside faucets, cut the branch ines approximate y two inches from the fitting on the main water ine. Insta an

e bow on the end of the pipe nearest the outside faucet and a cap on the end connected to the existing water ine.

Insta piping from the tee insta ed on the in et ine to the water softener to the e bow insta ed on the pipe to the

outside faucet. Fo owing this procedure wi resu t in a ines in the house, with the exception of the outside faucets,

but inc uding the water heater and therefore the hot water ines, being supp ied with soft water.

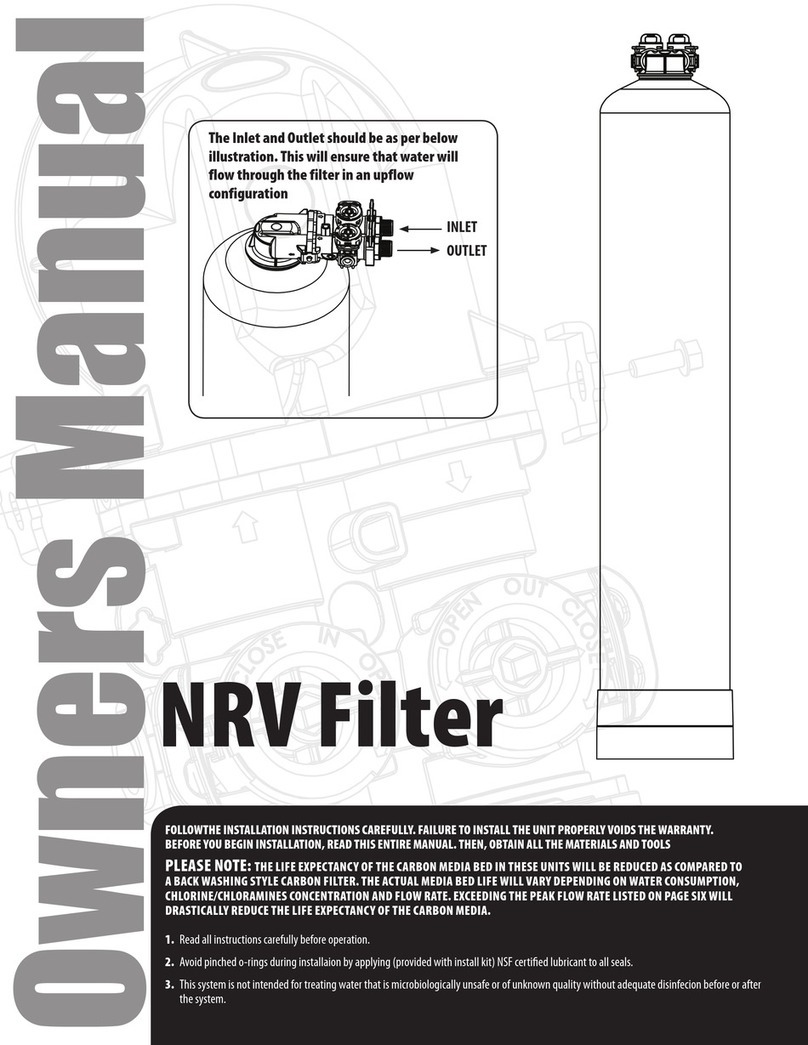

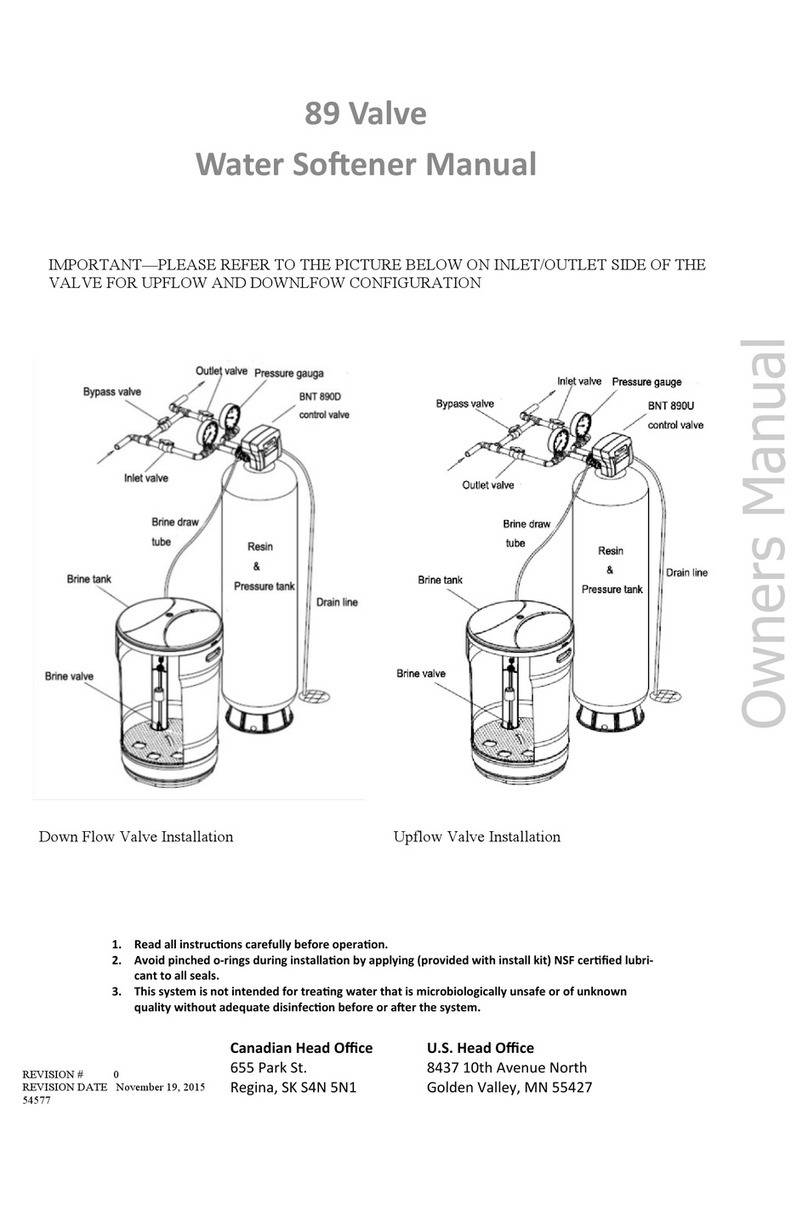

3. Fami iarize yourse f with the ocation of the in et, out et and drain on the contro va ve. Be very carefu not to get the

contro s wet.

3

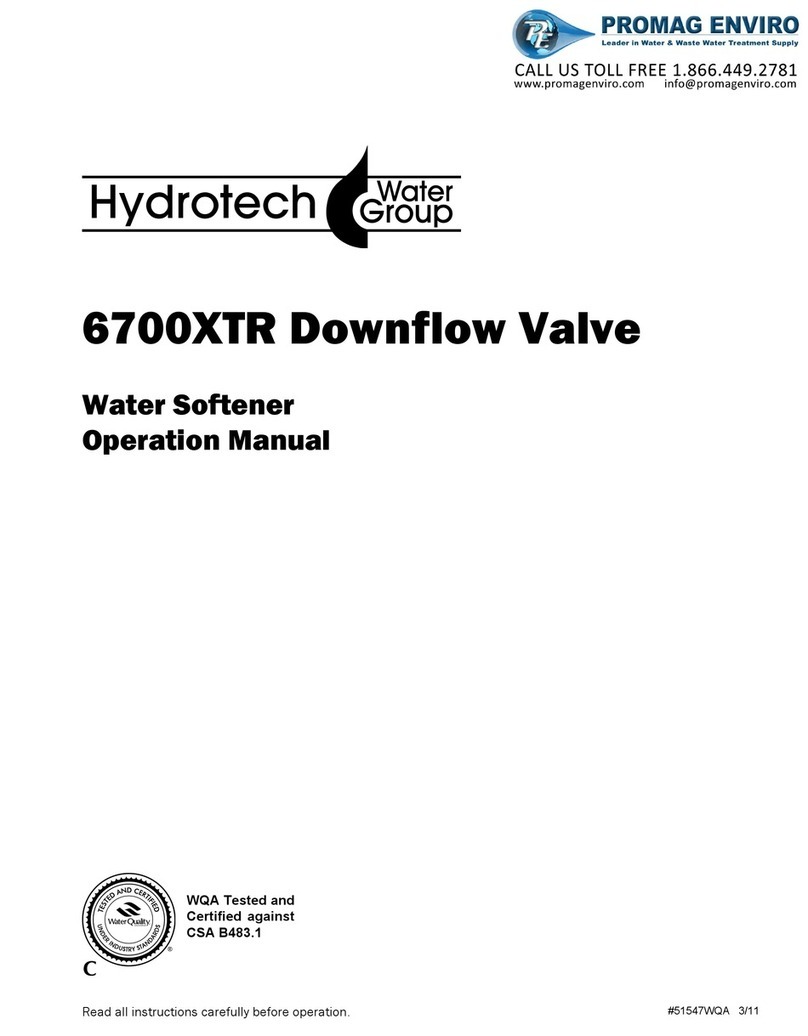

Figure 2

Figure 1

E ectrica Pane

Ground Strap

Po y Pipe

Ground

From

Pane

Po y Pipe

Softener

c/w P astic Bypass

Copper Pipe

Water Meter

Outside Water Line For Outside & 3rd Tap Comes From Meter

Fi tered Water Line in Home

Unfi tered Water Bypass

Loop Cut & Capped

Ground Strap Required

Because of Break in Continuity