Contents __________________________________________________________________________

1. About the machine / technical data......................................................................................................1

2. Proper use..................................................................................................................................1

2.1. Approved cleaning agents...............................................................................................1

2.2. Approved cleaning agents with technical ventilation........................................................1

2.3. Non-approved cleaning agents........................................................................................2

2.4. Standards........................................................................................................................2

3. Operating principle....................................................................................................................2

3.1. Description of machine functions.....................................................................................2

3.2. Safety information...........................................................................................................2

4. Transport....................................................................................................................................2

4.1. Handling..........................................................................................................................2

4.2. Transport aids.................................................................................................................2

4.2.1. Transport using a crane.......................................................................................2

4.2.2. Transport using a fork-lift .....................................................................................2

5. Setup / commissioning .............................................................................................................3

5.1. Securing the device / stability..........................................................................................3

5.2. Space required................................................................................................................3

5.3. Acceptable ambient conditions........................................................................................3

5.4. Preventing electrostatic charge.......................................................................................3

5.4.1. IBS pump...........................................................................................................3

5.4.1.1. Parts Cleaning Device.......................................................................................3

5.4.1.2. Electrical connection by the customer................................................................3

5.5. Additional equipment.......................................................................................................3

5.5.1. IBS collecting tray..............................................................................................3

5.5.2. IBS exhaust system...........................................................................................3

5.6. Disposal..........................................................................................................................3

5.7. Precautionary measures to be taken by the operator ......................................................4

6. Operating the machine..............................................................................................................5

6.1. Controls...........................................................................................................................5

6.2. Assembly and adjustment ...............................................................................................5

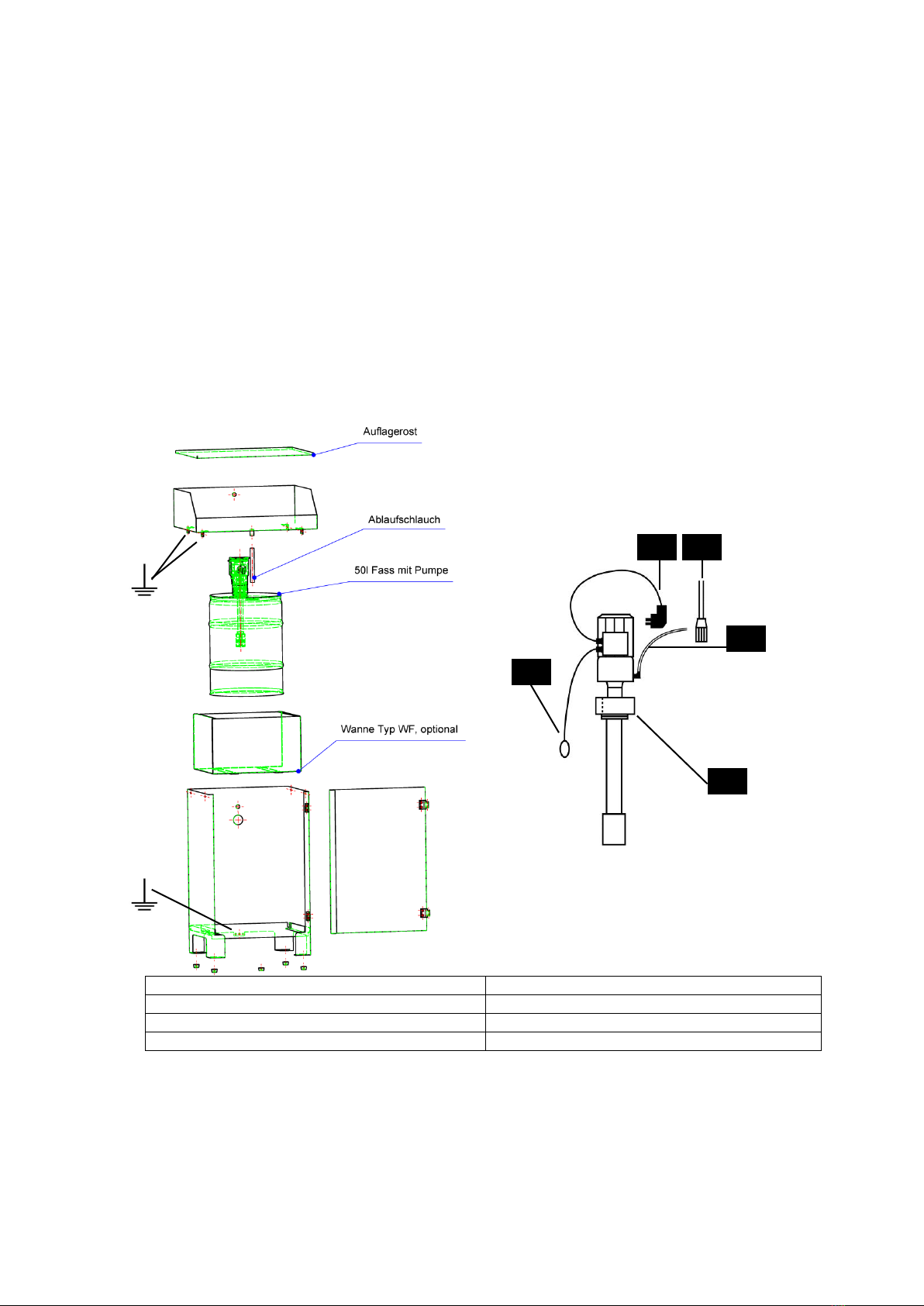

6.2.1. Assembling the Parts Cleaning Device..............................................................5

6.2.2. Assembling the IBS special pump .....................................................................5

6.2.3. Operation...........................................................................................................6

6.3. Fault identification and troubleshooting ...........................................................................6

6.4. Personal protective equipment........................................................................................6

7. Maintenance / cleaning .............................................................................................................7

7.1. Maintenance / cleaning work...........................................................................................7

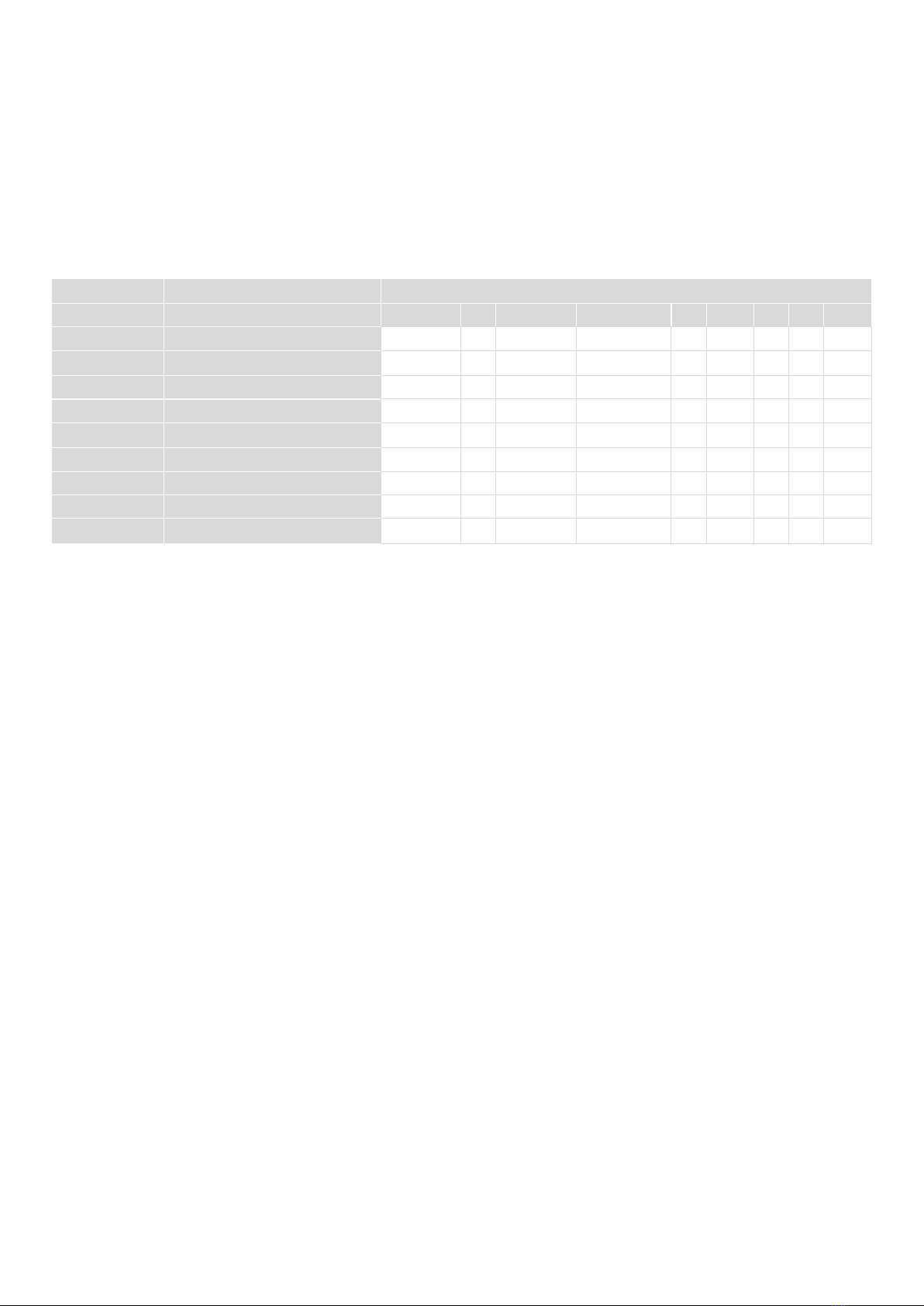

8. Spare parts list...........................................................................................................................7

9. Accessories list.........................................................................................................................8

Annexes