Description

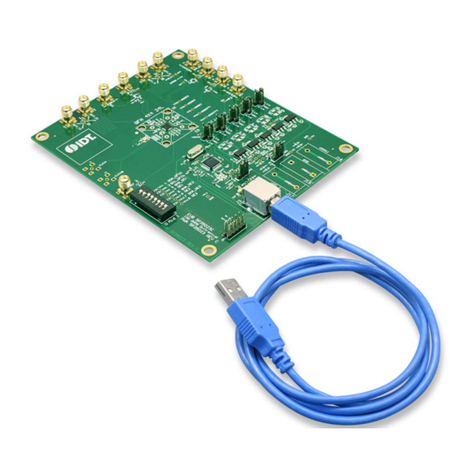

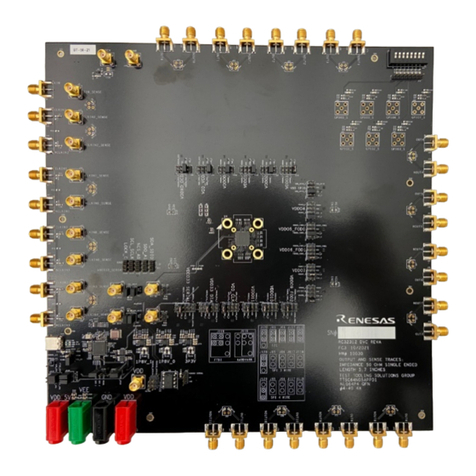

The ZMOD4410 Evaluation Kit (EVK) is designed for evaluating

IDT’s ZMOD4410 Gas Sensor Module for TVOC. The total volatile

organic compounds (TVOC) measurement is one of the indicators

for indoor air quality (IAQ). In addition, a measurement mode is

provided to trigger an external device (e.g., fan, ventilation) based

on the air quality change.

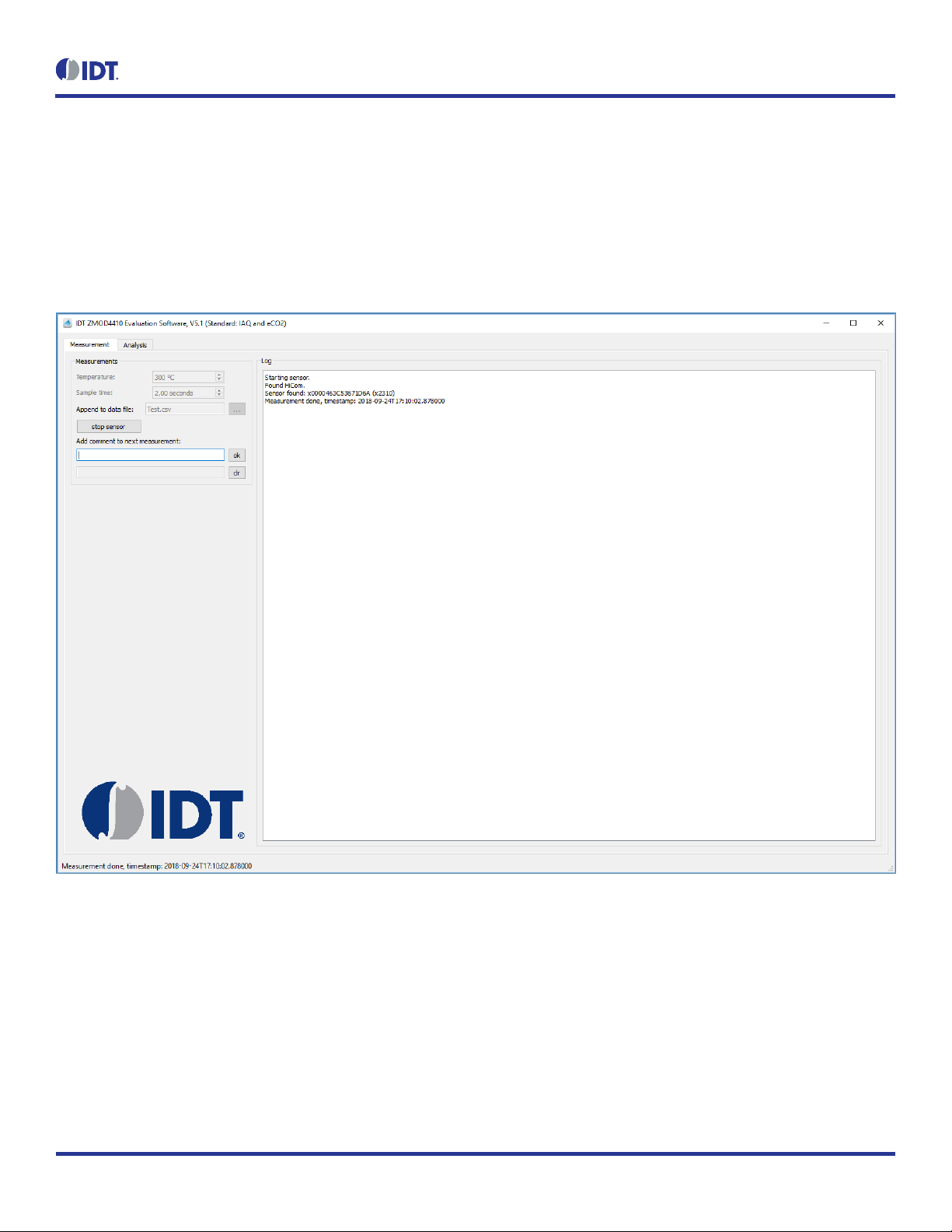

The ZMOD4410 Evaluation Software allows Windows®-based

operating systems to communicate with the ZMOD4410 EVK via a

USB connection on the user’s computer, which functions as a

master. The software and additional related documentation is

available on the IDT website.

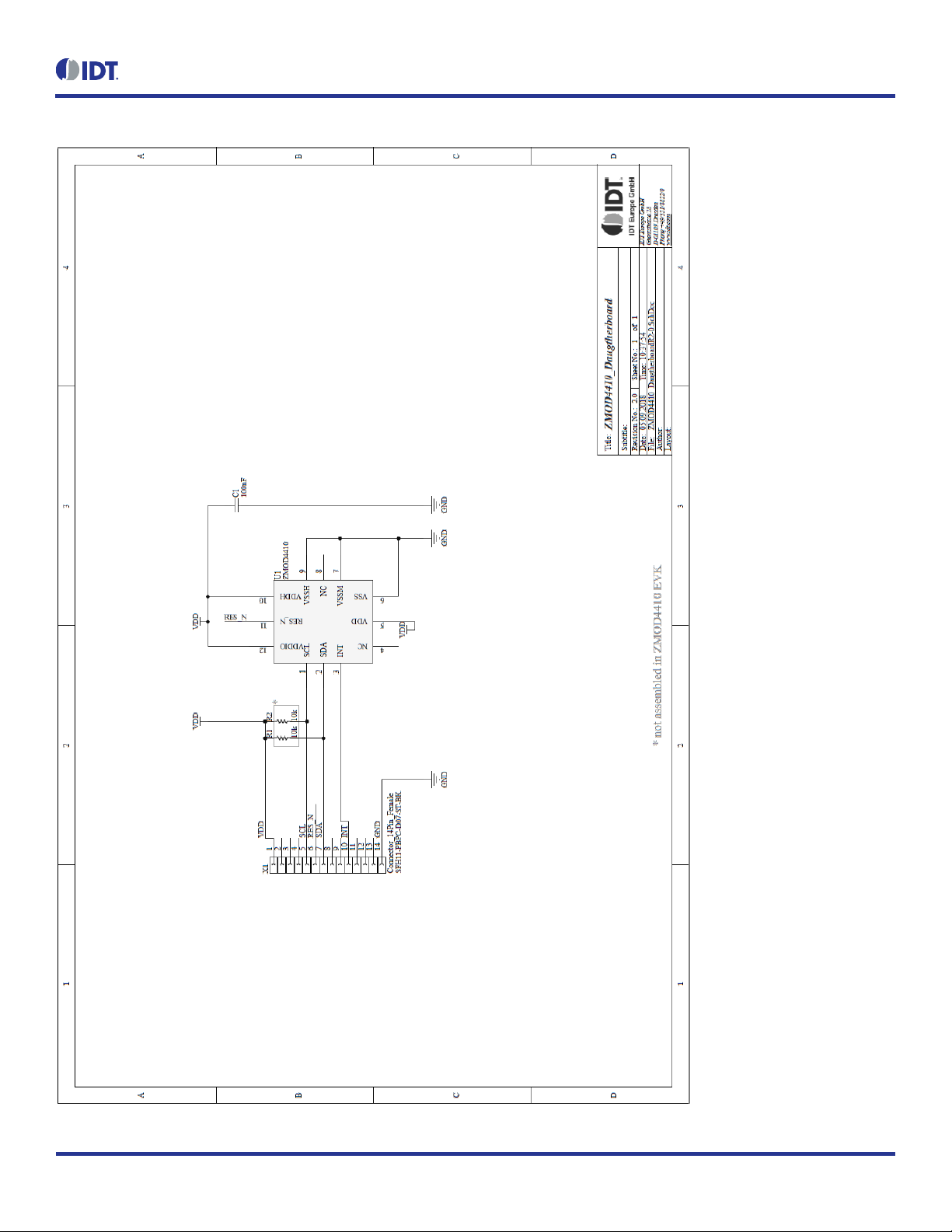

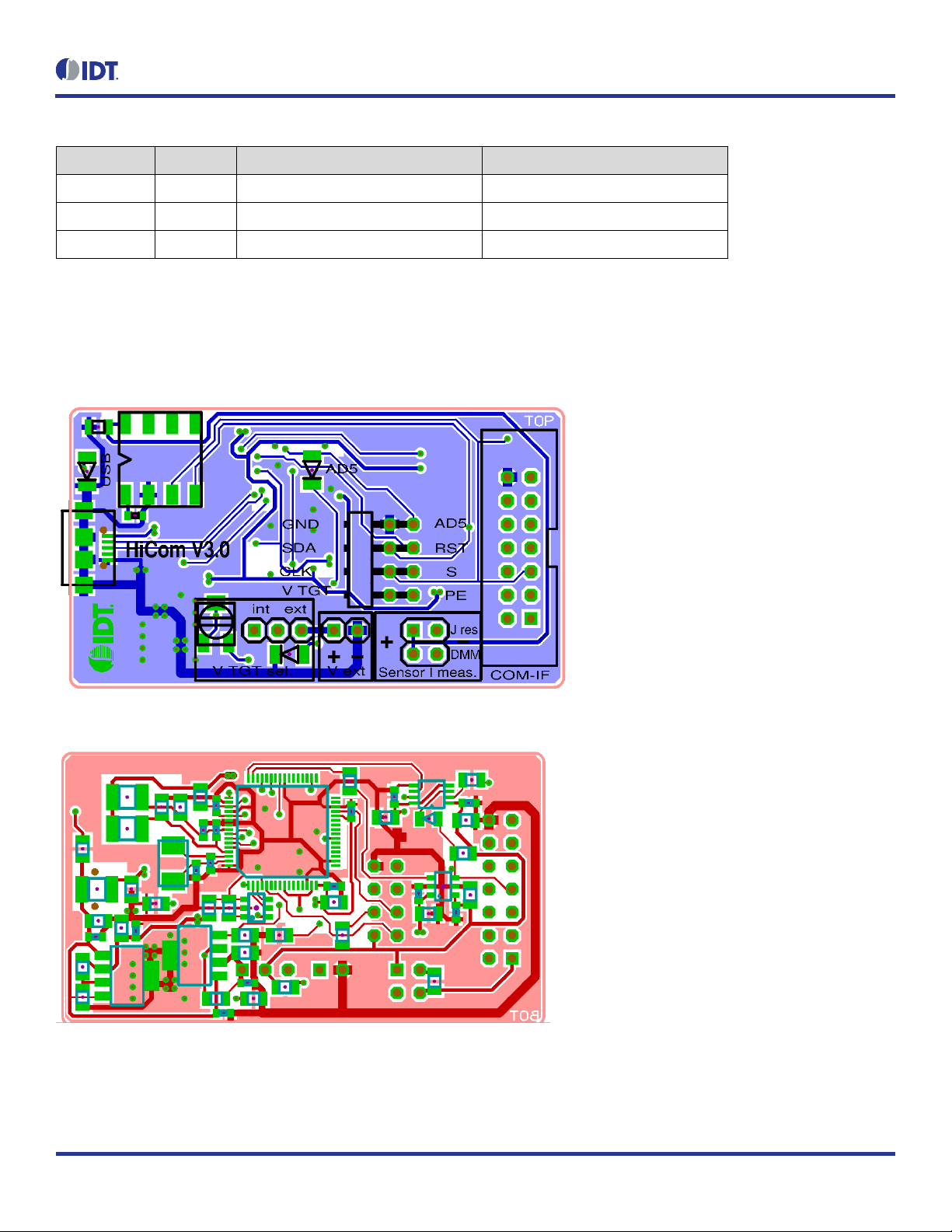

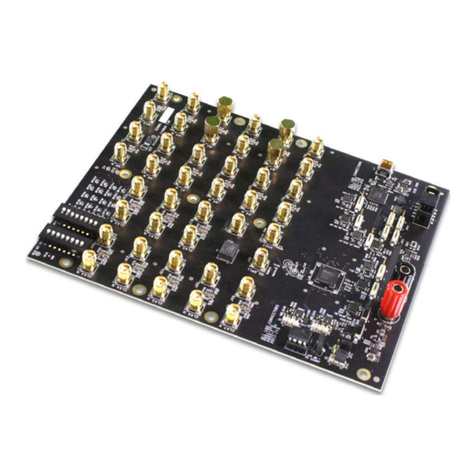

The EVK’s Communication Board (HiCom) handles the interface

between the user’s computer and the ZMOD4410 module mounted

on the ZMOD4410 Sensor Board (Daughter Board). Note: Only one

Communication Board with one Sensor Board can be connected to

the computer at a time.

The ZMOD4410 Evaluation Kit uses an FTDI controller on the

Communication Board to handle the USB protocol, translate

communications, and synchronize communications with the I2C

interface. The Sensor Board includes a decoupling capacitor.

The Communication Board has devices mounted on both sides.

The components on the top side generate a stable supply voltage.

A potentiometer can be used to adjust the internal supply voltage

in the typical range from 1.7V to 3.6V. Alternatively, the user’s

external supply voltage can be used. The intensity of the adjacent

LED is proportional to the supply voltage.

Features

User-friendly EVK expedites configuration and evaluation of

the ZMOD4410 Gas Sensor

Operates with IDT provided software; either with executable

ZMOD4410 GUI or alternatively with firmware programming

examples for Windows and Linux

The modular design of the EVK allows simple connection of

Sensor Boards for different gas sensor derivatives and easy

integration with other sensor products via the I2C interface

The required ZMOD4410 Evaluation Software is available for

download on the IDT website, which also provides background

information on TVOC, gas sensing, and sensor programming.

Supports different methods of operation, including Low Power

Additional pins to measure power consumption, supply

voltage, and GPIO trigger for external device

The bill of materials (BOM) and schematics for the ZMOD4410

Communication Board and Sensor Board are provided at

www.IDT.com/ZMOD4410-EVK.

ZMOD4410-EVK Contents

ZMOD4410 HiCom Communication Board

ZMOD4410 Sensor Board with ZMOD4410 Gas Sensor

Module

0.5m Type-B USB to Micro-USB Cable

ZMOD4410 Evaluation Kit