InCharged ICE-180 User manual

Description

The InCharge Energy ICE-180 is an All-in-One DC Fast Charger, which

supports both CCS and CHAdeMO standards with one or two connectors.

This DC All-in-One is designed for easy installation and high reliability. This

product is easy to operate with an intuitive touchscreen display that facilitates

access control, charging status, and help menus. The ICE-180 is ideal for

auto dealers, fleet charging and a variety of parking applications where DC

charging is needed in minimal space.

Key Benefits and Features

•150 to 1000Vdc output voltage range supports new high voltage DC

charging voltages

•180kW rated output power

•User friendly control interface allows for PIN or RFID accessibility

•Tempered glass touchscreen LCD display for added durability and

daylight readability

•OCPP 1.6 standard supports integration into In-Control, In-Charge’s

EVSE management platform

•LTE Modem and LAN for connectivity to In-Control

•Compact design for space saving power-to-footprint ratio

•TUV certification to UL 2202 to ensure safety

•480V 3-phase input for high efficiency conversion

•TUV Certified

The ICE-60, 120, and 180

share the same housing

Specifications

•Available with single CCS, Dual CCS1 and CCS1 & CHAdeMO connectors

•DIN70212 and ISO15118-2 protocols supported

•Materials and Finish: Enclosure - Hot galvanized steel; Facade - Plastic; Screen - Tempered glass

•Dimensions: 29.5”(D) x 27.5”(W) x 68.9”(H) / 750mm * 700mm * 1750mm

•Weight: 900lbs / 408kg

ICE-180 All-in-One

180kW DC Fast Charger

Ordering Information

Configuration SKU

ICE-180kW DC Fastcharger - Dual CCS1 ADC-180- 480-C1C1-AC1R

ICE-180kW DC Fastcharger - CCS1 & CHAdeMO ADC-180- 480-C1CH-AC1R

ICE-180 - CC CCR IDC-180-480-C1C1-AC1C

ICE-180 - CC Cold Weather IDC-180-480-C1C1-AC1R-CW

ICE-180 - C1LC1L IDC-180-480-C1LC1L-AC1R

ICE-180 - CJ CCR IDC-180-480-C1CH-AC1C

ICE-180 - CC2 IDC-180-480-C1C2-AC1R

ICE-180HC - CC IDC-180HC-480-C1C1-AC1R

Technical Specifications

Configuration SKU

Voltage 480 Vac +/- 10 %

AC Input Power Connection 3-phase: L1, L2, L3, GND

Frequency 60 Hz

Recommended breaker 300A 3W+G

SCCR 25 kAIC

Max Current Draw 222A

Power factor >0.99

THD - Current < 5%

Output Parameters Value

Voltage 150 - 1000Vdc

Current - Max 300A@300V / 300A@500V / 180A@1000V

Power - Max 180kW

System Effciency - Max >95%

Controls and Interface Value

Charging Connectors CCS1, CHAdeMO

HMI 7” TFT LCD Display

Communication OCPP 1.6J

Network Connection 4G/5G modem; LAN 10/100M

RFID ISO14443 Type A & S50, S70 MIFARE

Language English (others available on request)

Environment Value

Temperature - Operating -4°F to 113°F/ -20°C to +45°C * (Optional: -40°F / -40°C)

Temperature - Storage -40°F to 158°F/- 40°C to +75°C

Humidity 0 - 95%

Altitude - Operating 6560ft (2000 m)

Protection - Intrusion IP54, NEMA 3R; indoor and outdoor rated

General Value

Cable Length 16.4 ft (25ft available upon request)

Safety and EMI UL2202, CE, EN6100-6-3, EN61851-1/-23/-24

Certification Number 72212743

*Derating characteristics apply at extreme temperatures

GET IN TOUCH 818.697.GOEV

1433

Fifth Street, Santa Monica, CA 90401

hello@inchargeus.com | inchargeus.com

©2022 In-Charge US | All Rights Reserved

2

IMPORTANT SAFETY INSTRUCTIONS

Please read the operating instructions and notes carefully before starting operation in order

to prevent accidents. The "Caution, Attention, Warning and Danger" statements in the

products and product manual do not represent all safety matters to be observed and are

intended to supplement various operational safety precautions.

During the various operations of our products and equipment, it is necessary to comply with

relevant National Safety Regulations and strictly observe the precautions and special safety

instructions of the related equipment.

Electrical Safety

High Voltage

Danger

Since some parts of this power system are under high voltage during operation,

direct or indirect contact can be fatal.

It is necessary to comply with relevant National Safety Regulations during the installation of

the Portable DC Charger. Personnel who install and maintain this equipment must be

qualified to work with high DC voltage up to 1000Vdc and 3-phase AC voltage up to 500Vac.

It is strictly forbidden to wear watches, bracelets, bangles, rings and other conductive

objects on the wrist during installation and maintenance.

If there is water inside the DC Charger enclosure, AC power and DC connector must be

disconnected immediately. During operation in a humid environment, water should be strictly

prevented from entering the equipment.

During installation, it is strictly forbidden to operate the DC Charger and an “Operation

prohibited” signboard must be used.

Danger

Construction operation of high voltage lines may cause fire or electric shock.

The wiring area and the area where the line passes through for AC cables must

comply with national and local regulations and norms. As this device utilizes

high voltages do not attempt to install this equipment if you are not a qualified

electrician.

Tools

Warning

Special tools must be used during various operations involving high DC and AC

voltages.

3

Thunderstorm

Danger

It is strictly forbidden to carry out live installation and maintenance work during

thunderstorms.

A strong electromagnetic field will be produced in the atmosphere during a thunderstorm.

Therefore, the equipment should be well grounded to avoid damage to the equipment due

to lightning strikes.

Static Electricity

Caution

Static electricity generated by the human body may damage electrostatic

sensitive components on the circuit boards, such as the large-scale integrated

circuit (IC), etc. Before handling any patch boards, circuit boards and IC chips,

it is necessary to wear an anti-static wrist strap with the anti-static wrist strap

wire connected to Ground to avoid damage to sensitive components due to

static electricity.

Short circuit

Danger

During operation, it is strictly forbidden to short-circuit the positive and negative

of the DC Charger DC distribution or short-circuit any DC distribution polarity to

Ground. The DC Charger is a high voltage DC power supply, and short circuit

may cause damage to the DC Charger and personal safety hazards.

During work with High Voltage DC output, it is necessary to strictly check the polarity of

cables and interface terminals.

The space for DC power distribution work is compact and attention should be paid to

planning cable routing etc. before starting any installation work.

Insulated tools must be used.

During live work, attention should be paid to keeping hands, arms tools etc. away from

live high voltage parts to avoid accidents.

Others

Sharp Corners of Objects

Warning

During the handling of equipment by hand, it is necessary to wear protective

gloves to prevent injuries caused by sharp objects.

Power Cable

Caution

Make sure that the cable label is correct before the connection of cables.

Signal Cables

Caution

Signal cables should be kept away from power cables, with a minimum

distance of 100mm.

4

Table of Contents

1General Product Description ...................................................................................................................... 5

2General Characteristics.............................................................................................................................. 5

2.1 Technical Specification ....................................................................................................................... 5

2.3 Model description ............................................................................................................................... 7

2.4 Standards............................................................................................................................................. 7

3Product Parts Presentation......................................................................................................................... 8

4Installation.................................................................................................................................................. 9

4.1 Grounding instructions........................................................................................................................ 9

4.2 Unpacking and visual inspection ......................................................................................................... 9

4.3 Assembly/placing instructions............................................................................................................. 9

4.3.1 Preparation of concrete foundation........................................................................................... 10

4.3.2 Cabinet Installation..................................................................................................................... 11

4.3.3 Power cables connections .......................................................................................................... 12

4.3.4 Riser Installation

5Start-Up .................................................................................................................................................... 14

5.1 Verification and inspection................................................................................................................ 14

5.2 Switch on .......................................................................................................................................... 14

6User Manual ............................................................................................................................................. 16

6.1 Output connector

.............................................................................................................................. 16

6.1.1 CCS Connector............................................................................................................................ 16

6.1.2 CHAdeMO Connector ................................................................................................................. 17

6.2 Operation instructions....................................................................................................................... 17

Appendix 1 Engineering and Technical Parameters .................................................................................... 19

Appendix 2: Alarm information ................................................................................................................... 21

Appendix 3: Error codes and possible solutions.......................................................................................... 22

5

1General Product Description

The ICE- 60/120/180 is able to fast charge all electric vehicles compliant with Combined

Charging System (CCS) and CHAdeMO charging system standards.

IP55 for use in harsh environments

This charger is rated to charge at full power at the following temperature range: -22°F~122°F

(-30℃~50℃)

LTE wireless modem support, RFID authorization and Mobile App payment support

2General Characteristics

2.1 Technical Specification

The Technical Specifications of the ICE-60/120/180 are shown in Table 1.

This system is intended to have at least one DC output connection (CCS and/or CHAdeMO).

6

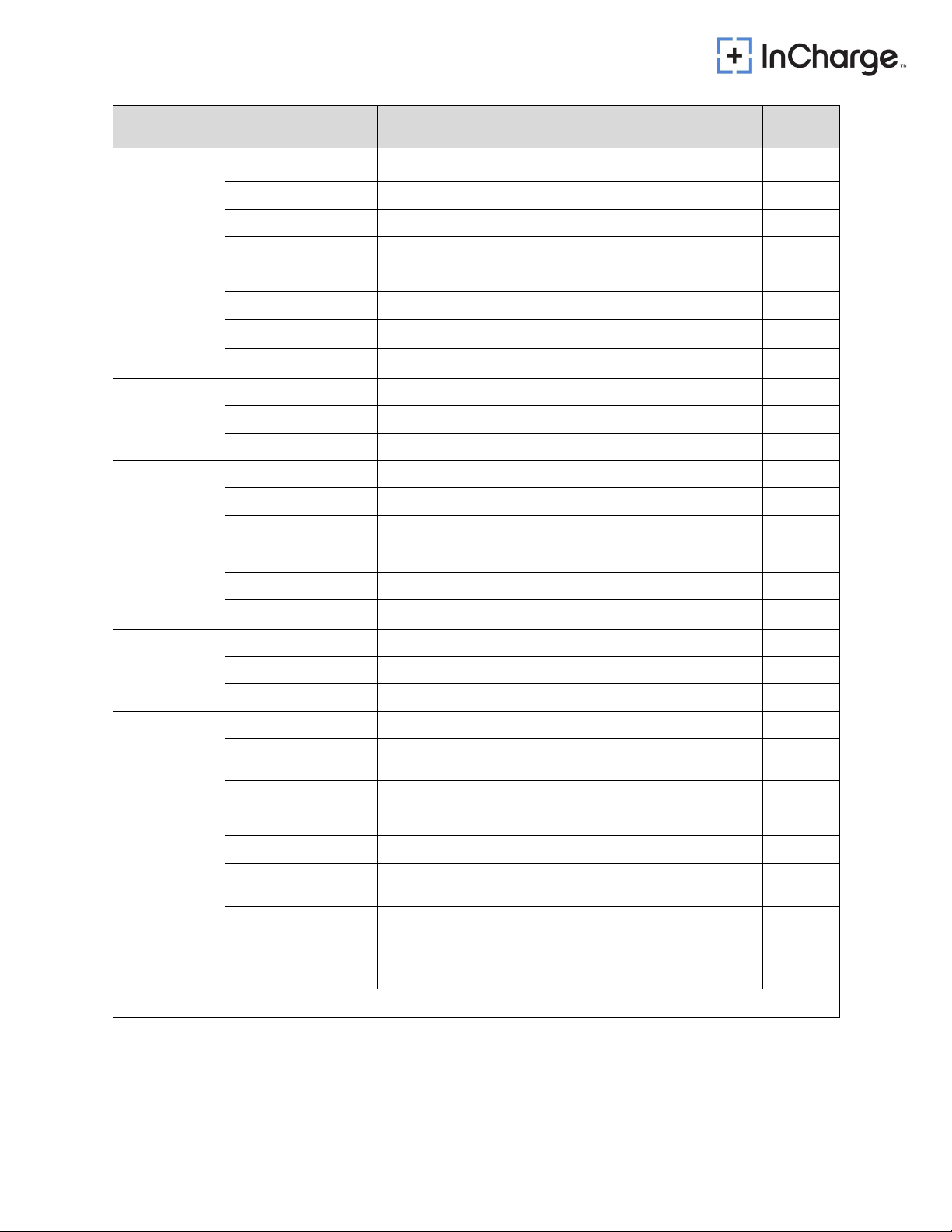

Technical Data Description Remarks

Nominal Input

Phases/Lines 3 phases + PE

Voltage

480Vac (+/-10%)

Frequency

45 – 60 Hz

Current 60:86A ;120:150A; 180: 222A

Power

60: 60kW ; 120: 120kW; 180: 180kW

Power factor

≥

0.99

System Efficiency

≥

94.5% (Full load)

DC Output

CCS1

Voltage

150~1000Vdc

Current

60: 60A @ 1000V; 120: 120A @ 1000V; 180: 180A @ 1000V

Nominal Power

180kW

DC Output

CHAdeMO

Voltage

200~500Vdc

Current

125A

Nominal Power

62.5kW

Cabinet

Dimensions(W*D*H)

700*750*1750

(

mm

)

Weight

60: 708lbs / 321kg;120: 804lbs / 364kg; 180: 900lbs / 408kg

Protection Degree

IP55

,

IK10

HMI and

Command Unit

Local interface

TFT Color touch display 7”

Communication

Router 4G/5G (GSM or LTE)

Protocol

OCPP1.6

Environment

conditions

Operating temperature1

-40°F ~ 167°F ( -40°C ~ +75°C), Derating After 131°F (55°C)

Transportation/ Storage

temperature -40°F ~ 167°F ( -40°C ~ +75°C)

Humidity

5%RH~95%RH

Place of installation

Indoor / Outdoor

Altitude

2000m (6561 ft)

Sound Noise ≤

65dB (nominal input/output power, the environment temperature

is 77°F (25°C).)

Atmospheric pressure

80KPa~110KPa

Overvoltage category

II

Protection class

Class I

Note 1:

-40℃~+75℃,derating from 55℃

7

2.3 Model description

NRTL Model Number Model Configuration Remarks

EXP-180K2-FDW-UU2 ICE-180-CC CCS-1 + CCS-1 180kW

EXP-180K2-FDW-UC2 ICE-180-CJ CCS-1 + CHAdeMO

180kW

EXP-120K2-FD-UU2

ICE-120-CC

CCS-1 + CCS-1

120kW

EXP-120K2-FD-UC2

ICE-120-CJ

CCS-1 + CHAdeMO

120kW

EXP-60K2-FD-UU2

ICE-60-CC

CCS-1 + CCS-1

60kW

EXP-60K2-FD-UC2

ICE-60-CJ

CCS-1 + CHAdeMO

60kW

2.4 Standards

The EVSE (Electric Vehicle Supply Equipment) complies with the following standards:

Table 2 Applicable Standards

Technical Data Norm Remarks

Applicable

Standards

IEC 61851-11

IEC 61851-232

IEC 61851-243

1 IEC 61851-1 2017: Electric vehicle conductive charging system. Part 1: General

Requirements

2 IEC 61851-23 2014: Electric vehicle conductive charging system - Part 23: DC electric vehicle

charging station

3IEC 61851-24 2014: Electric vehicle conductive charging system - Part 24: Digital

communication between a DC EV charging station and an electric vehicle for control of DC

charging

8

3Product Parts Presentation

The charging system is composed of DC charging cabinet and DC charging connector. The

System can be installed outdoors.

The ICE-60/120/180 series fast DC Charger has various possible output combinations as shown in

section 2.3 Model description:

Figure 1: External View of ICE-60/120/180

9

4Installation

4.1 Grounding instructions

An equipment grounding conductor or a grounded, metal, and permanent wiring system is required

for the EVSE charger connection. This should be run with circuit conductors and connected to the

equipment grounding bar or lead on the EVSE.

4.2 Unpacking and visual inspection

Check that the exterior packaging has been damaged by mechanical impacts or any accidents

during transportation

If applicable, check that the exterior panels of the ICE Charger are in perfect condition

Check that the interior of the Charging Station is clean

Check that the door of the Charging Station is working properly

Check for proper Charging Station protective ground connection point, which should be

interconnected with the low voltage switchboard ground connection during the installation

4.3 Assembly/placing instructions

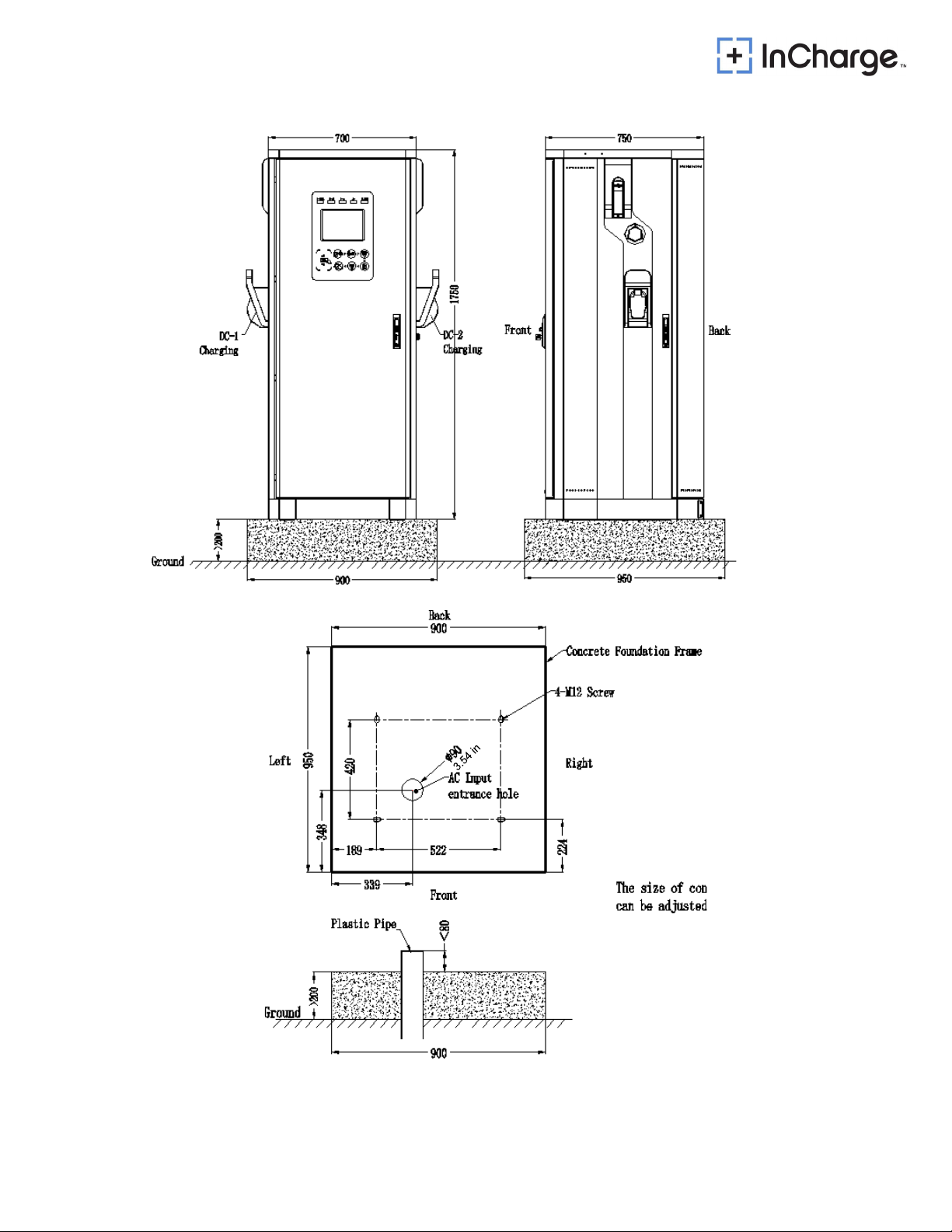

As shown in the figure below, the concrete foundation should be made, and the height of the

base should not be less than 8in (200 mm) above grade.

It is recommended to reserve a Φ3.5in (90mm) plastic pipe at the cable entrance, and the height

of the pipe extending out of the foundation horizontal plane shall not be more than 3.15in

(80mm).

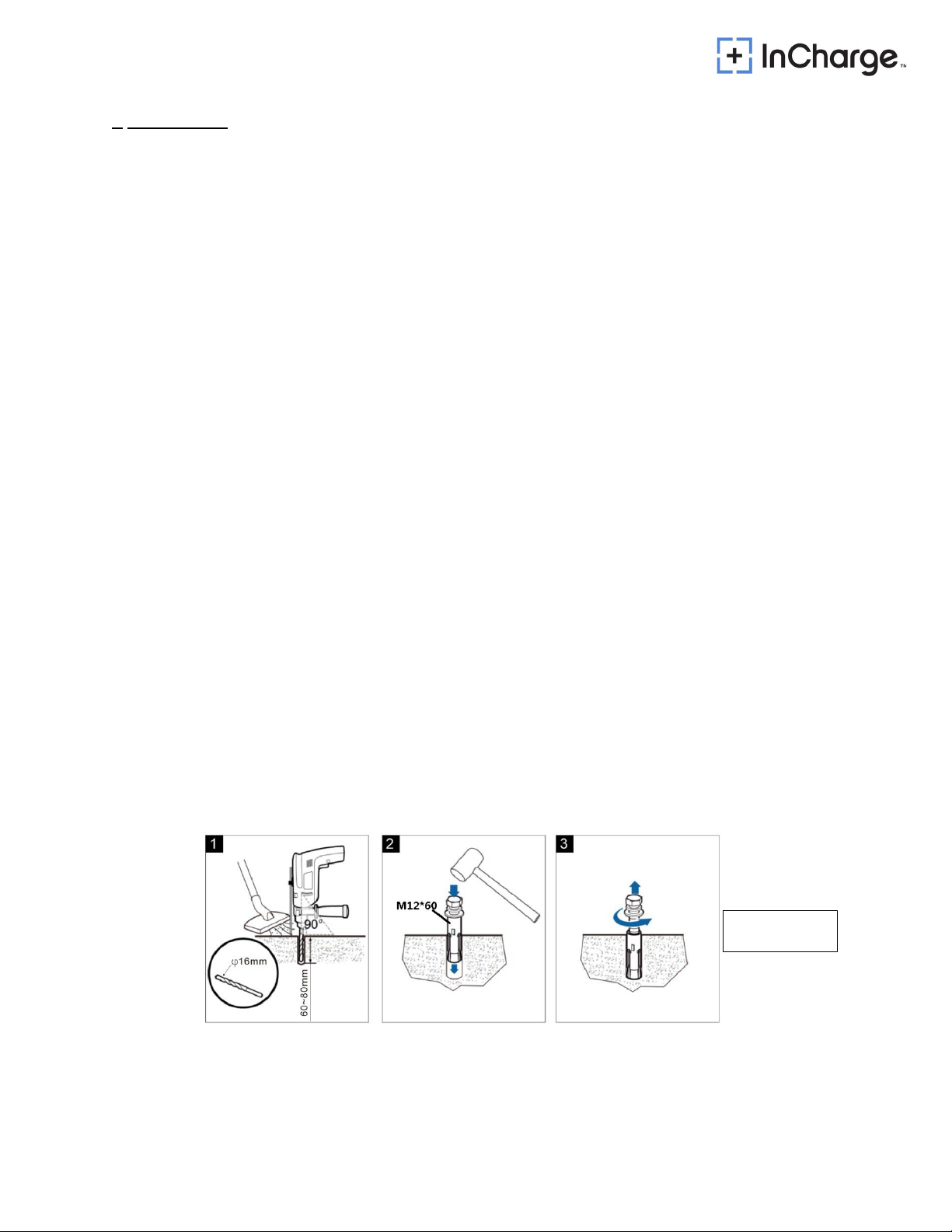

As shown in the figure below, mark the installation holes of four M12 expansion bolts on the

concrete foundation.

Open 4 holes on the concrete foundation, select the percussion bit of Ф 0.63in (16mm) type,

and use the percussion drill to drill the holes perpendicular to the ground at the above marked

hole position, with the drilling depth of 2.36in~3.15in (60mm ~ 80mm).

Use four M12 × 60 expansion bolts equipped with attached accessories, slightly tighten the

bolts, vertically put them into the hole, and knock them with a rubber hammer until all the

expansion pipes enter the installation hole.

Screw off the bolt, spring pad and flat pad in turn counterclockwise.

Figure 2: Anchor Installation

M12 Bolt: 12mm

or ½ in

10

4.3.1 Preparation of concrete foundation

Figure 4: Concrete Pad

Figure 3: Concrete foundation top view

27.56 in

68.90 in

29.52 in

35.43 in

37.40 in

>7.87 in

35.43 in

37.40 in

37.40 in

13.35 in

13.70 in

7.44 in

20.55 in

8.82 in

>7.87 in

35.43 in

3.15 in

11

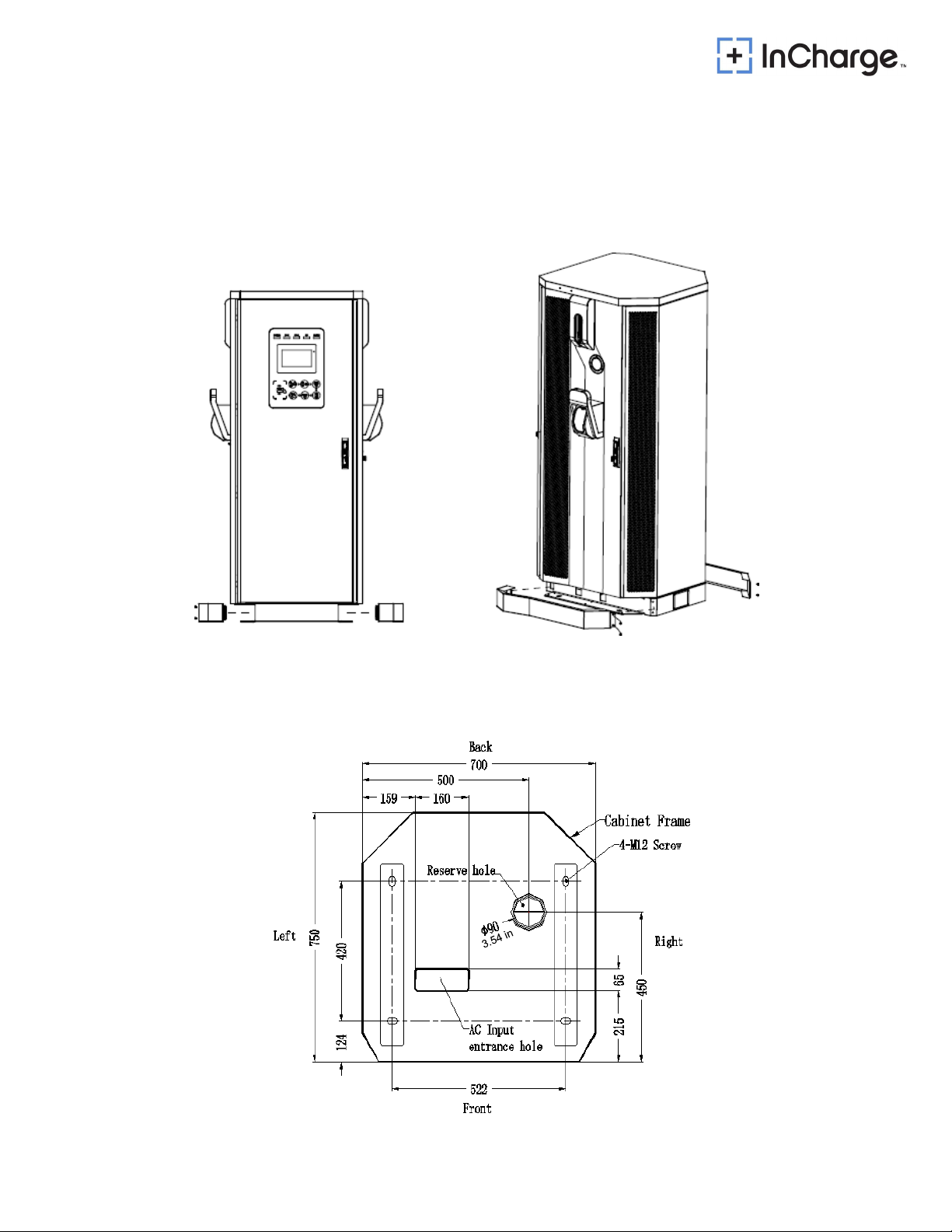

4.3.2 Cabinet Installation

As shown in the figure below, the protective covers on both sides of the steel base of the

cabinet can be removed, and the cabinet can be transported to the concrete foundation by

forklift.

Align the installation hole of the cabinet base and fix the cabinet to the concrete foundation with

expansion bolts.

Figure 5:EVSE cabinet installation

27.56 in

19.69 in

6.26 in

6.30 in

29.52 in

37.40 in

4.88 in

20.55 in

8.46 in

17.72 in

2.56 in

12

Table 4-AC input wiring cables

EVSE Top View

4.3.3 Power cables connections

End terminals for input wiring: 4 (four) end terminals for 3 phases + protective ground.

Figure 6: AC Input Wiring

Max. Power of

charger

The section for AC

feed cables AWG

Amperage

Specification of

terminal screw

180kW 3*185+2*95mm23/0 320A

L1/L2/L3 is M10 PE is

M8

120kW 3*120+2*70mm22/0 224A L1/L2/L3 is M10 PE is

M8

60kW 3*95+2*50mm21 115A

L1/L2/L3 is M10 PE is

M8

Notes:

The AC feed power cables to the charger are not included.

The AC feed power cables should be no less than 90℃temperature resistant grade.

The protective MCCB must be installed on the customer's distribution cabinet, and the upper

MCCB capacity shall not be less than 1.25 times of the input current.

It is recommended that the upper MCCB should not be equipped with RCD function.

This system is to be connected to a grounded, metal, permanent wiring system; or an

equipment-grounding conductor is to be run with circuit conductors and connected to

equipment-grounding terminal or lead on battery charger.

13

Figure 7: UL Wiring Diagram

14

4.3.4 Riser Required Installation

A riser is required to be installed if the installation location has a preexisting

concrete foundation.

A riser is required to be used if the customer does not want to break ground to run

the power wires.Therefore, any modifications to the chargers housing, such as

cutting holes into the unit, will void all warranties.

The riser places the ICE-60, ICE-120, ICE-180 up six inches.

Using a riser will still allow the charges HMI to still be ADA compliant.

Comes with three plates to cover the side wall holes. All plates are the same, but holes

can easily be punched out of the side wall cover for the power lines at the desired entry

point.

Name

SKU

Rapid Base Platform RMA-DP-FD

15

5Start-Up

5.1 Verification and inspection

Check if the bolts of the AC and protective ground cables of the EVSE are correctly tightened to

the specified torque. The torque values are as follows:

M8: 20ft-lbs (15ft-lbs on M8 Ground screws)

M10: 40ft-lbs

Check the resistance between the EVSE protective ground and the low voltage switchboard

ground connection; the value must be according to local codes.

Check the resistance on the Grid AC between phases and between phase and PE. Also check

resistances between DC+/DC-/PE to ensure no dead shorts.

Check that power modules panel address setting is correct.

Before switching ON all the fuses and circuit breakers, check the supply voltage between lines:

it must be 380Vac-520Vac. Also check between phases and phase to ground. Voltage should

be 480V +/- 5% P to P and 277V +/- 5% P-PE for a 480V feed

5.2 Switch on

Switch on the circuit breakers in the charging pile, Q1 and Q2 in turn.

AC Input MCB For Rectifier Module (Q1) AC Input RCD For Auxiliary Power(Q2)

16

Wait for a few seconds. The display will present a picture as below:

Figure 8: Loading Screen

Finally, the display will present the following charging screen

CCS1+CHAdeMO Units:

Figure 9: Charging screen

Before attempting to install or start up the charger must ensure that the safety instructions in

this manual have been carefully read and observed by trained personnel. Keep this manual with

the charger for future reference.

This manual suits for next models

2

Table of contents

Other InCharged Batteries Charger manuals