5

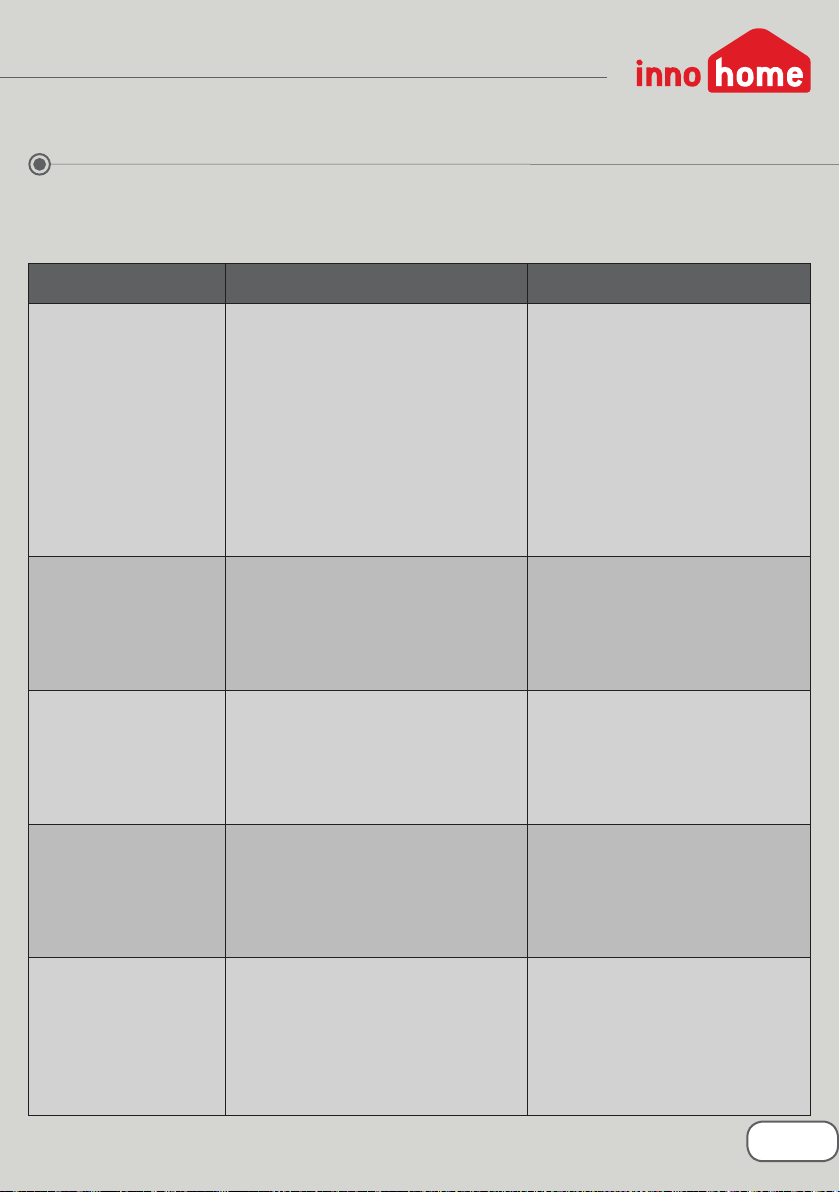

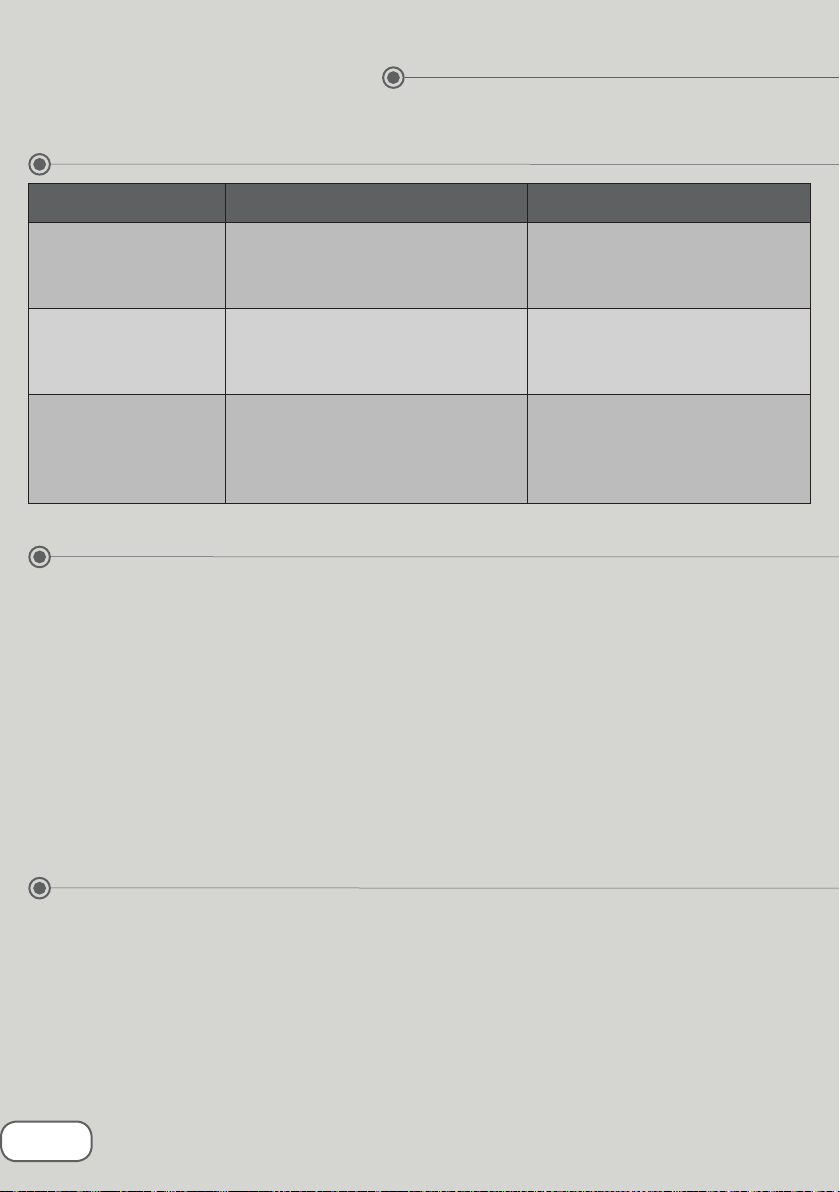

1.4 Meaning of alarm signals

The Intelligent Heat Sensor signal has a higher tone than the Control Unit signal.

1. Innohome Stove Guard and how to use it

Sound Meaning Course of Acon

Intelligent Heat Sensor: a

short ‘beep’ every few sec-

onds

The Intelligent Heat Sensor has detected a

high temperature or a fast temperature rise

on the cooker surface (Overheating Moni-

tor). This is a pre-alarm signal that starts one

minute before the actual alarm. Reseng the

pre-alarm signal cancels the gas/electricity

cut-o and reduces Intelligent Heat Sensor’s

sensitivity. The pre-alarm signal should be

reset only if the alarm was falsely triggered by

a normal cooking situaon.

Reset the pre-alarm signal by pushing the

push-buon once.

Intelligent Heat Sensor:

repetitive fast ‘beep, beep,

beep’

The Intelligent Heat Sensor has detected a

high temperature or a fast temperature rise

on the cooker surface (Overheang Monitor,

alarm signal). The gas/electricity has been cut

o.

First turn o the cooker hobs (mechanical

knobs only), then reset the alarm signal by

pushing the push-buon once.

Control Unit: a short ‘beep’

every few seconds

This is the Intelligent Timer’s pre-alarm signal

that is given one minute before the Intelligent

Timer cuts off the cooker’s gas/electricity

supply. Reseng the pre-alarm signal cancels

the gas/electricity cut-o.

Reset the pre-alarm signal by pressing the

push-buon once.

Control Unit: a short signal

at approximately 5 second

intervals

The gas/electricity has been cut o either due

to the Intelligent Timer function, detection

of an external alarm signal, or the Intelligent

Heat Sensor detecng a high temperature or

a fast temperature rise.

First turn o the cooker hobs (mechanical

knobs only), then reset the alarm signal by

pushing the push-buon once.

Control Unit: a short signal,

followed by a long signal

(‘be-beep’), at approximate-

ly 5 second intervals

The gas/electricity is cut o due to the auto-

mac fault diagnosis detecng an error in the

Intelligent Heat Sensor’s connection to the

Control Unit or in the funconing of a part of

the system.

First turn o the cooker hobs (mechanical

knobs only), then reset the alarm signal by

pushing the push-button once. Connect

the devices again, see section 5.2. If the

problem persists, contact the product re-

tailer.