LIMITED WARRANTY

Always use the cover when the transmitter is

not in the configuration phase. The cover

prevents the transmitter from getting dirt on

the soldering pads as well as getting ESD by

accidental touch of the soldering pads.

Connect input, output and power supply acc.

to fig. 2.

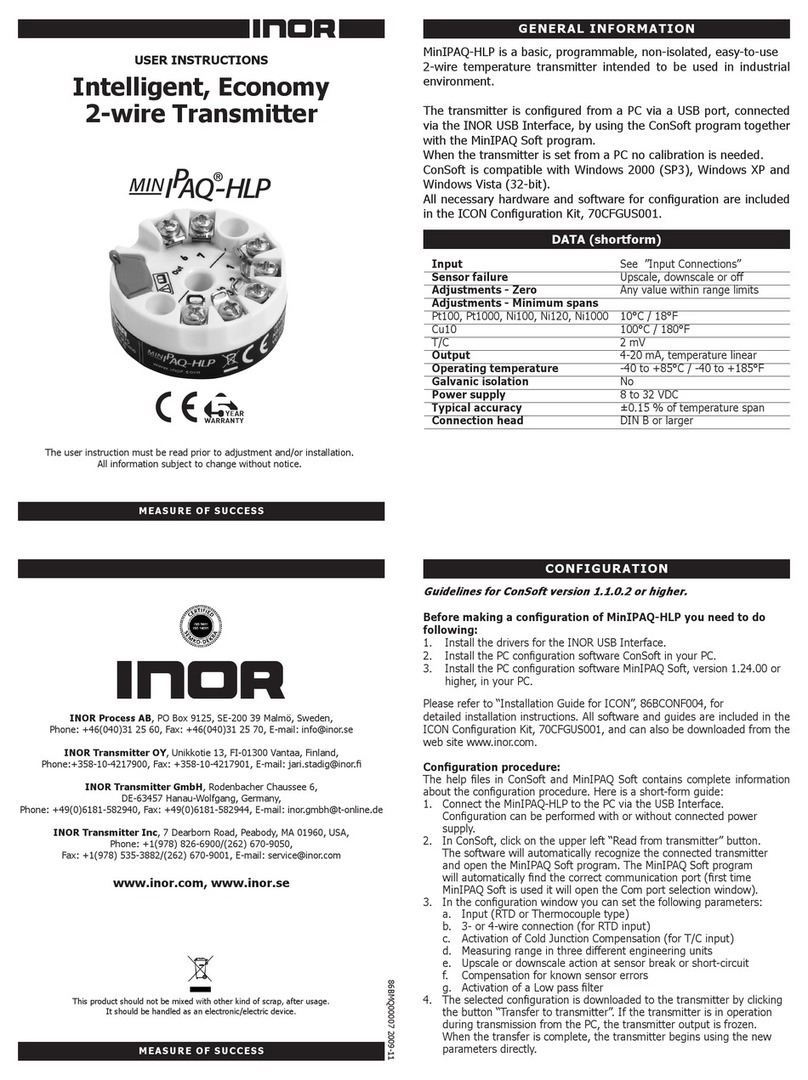

A convinient way to install the transmitter is

to use the INOR mounting kits for in-head and

DIN rail mounting, see figure 4 and 5. In order

to minimize measuring errors make sure the

connecting screws are tightened enough.

INOR Process AB, or any other affiliated company within the Inor Group (hereinafter jointly referred

to as ”Inor”), hereby warrants that the Product will be free from defects in materials or workmanship

for a period of five (5) years from the date of delivery (”Limited Warranty”). This Limited Warranty

is limited to repair or replacement at Inor’s option and is effective only for the first end-user of the

Product. Upon receipt of a warranty claim, Inor shall respond within a reasonable time period as to

its decision concerning:

1 Whether Inor acknowledges its responsibility for any asserted defect in

materials or workmanship; and, if so,

2 the appropriate cause of action to be taken (i.e. whether a defective product should be

replaced or repaired by Inor).

This Limited Warranty applies only if the Product:

1 is installed according to the instructions furnished by Inor;

2 is connected to a proper power supply;

3 is not misused or abused; and

4 there is no evidence of tampering, mishandling, neglect, accidental damage,

modification or repair without the approval of Inor or damage done to the Product by

anyone other than Inor.

This Limited Warranty is provided by Inor and contains the only express warranty provided.

INOR SPECIFICALLY DISCLAIMS ANY EXPRESS WARRANTY NOT PROVIDED HEREIN

AND ANY IMPLIED WARRANTY, GUARANTEE OR REPRESENTATION AS TO SUITABILITY

FOR ANY PARTICULAR PURPOSE, PERFORMANCE, QUALITY AND ABSENCE OF ANY

HIDDEN DEFECTS, AND ANY REMEDY FOR BREACH OF CONTRACT, WHICH BUT FOR

THIS PROVISION, MIGHT ARISE BY IMPLICATION, OPERATION OF LAW, CUSTOM OF

TRADE OR COURSE OF DEALING, INCLUDING IMPLIED WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. EXCEPT AS PROVIDED

HEREIN, INOR FURTHER DISCLAIMS ANY RESPONSIBILITY FOR LOSSES, EXPENSES,

INCONVENIENCES, SPECIAL, DIRECT, SECONDARY OR CONSEQUENTIAL DAMAGES

ARISING FROM OWNERSHIP OR USE OF THE PRODUCT.

Products that are covered by the Limited Warranty will either be repaired or replaced at the option of

Inor. Customer pays freight to Inor, and Inor will pay the return freight by post or other “normal”

way of transport. If any other type of return freight is requested, customer pays the whole return

cost.

Power supply: 6.5 to 32 VDC

Input: Pt100 (α=0.00385) 3-wire

Configuration Zero-point: -50 to +50°C

-60 to +120°F

Configuration Span: 50, 100, 150, 200, 300,

400, 500°C

100, 200, 300,

400, 600, 800, 1000°F

Adjustment Span: ±10% of span

(±5% for 600, 800, 1000°F)

Output: 4-20 mA temperature linear

Operating temperature: -40 to +85°C

-40 to +185°F

IN-HEAD MOUNTING DIN RAIL MOUNTING

Head mounting

kit (APAQ-HRF)

70ADA00011

Rail mounting kit 70ADA00013

INSTALLATION

DATA (shortform)

Adjustable In-head

Temperature Transmitters

for Pt100 Sensors

USER

INSTRUCTIONS

SWEDEN

GERMANY

USA

ADDRESS 1860 Renaissance Blvd., Suite 203

Sturtevant, WI 53177, USA

PHONE Domestic 1-888-430-INOR

(262) 884-4535

International +1-262-884-4535

FAX Domestic (262) 884-4537

International +1-262-884-4537

E-MAIL sales@inor.com

ADDRESS PO Box 9125

S-200 39 MALMÖ, Sweden

PHONE Domestic 040-31 25 60

International +46-40-31 25 60

FAX Domestic 040-31 25 70

International +46-40-31 25 70

E-MAIL support@inor.se

ADDRESS Rodenbacher Chaussee 6

Gebäude 805

D-63457 Hanau-Wolfgang

PHONE Domestic 06181-582940

International +49-6181-582940

FAX Domestic 06181-582944

International +49-6181-582944

E-MAIL inor.gmbh@t-online.de

www.inor.com

The manual must be read prior to adjustment

and/or installation. All information subject to

change without notice.

MADE IN SWEDEN

MEASURING MADE A LITTLE EASIER

86BAQ00004 2001-04

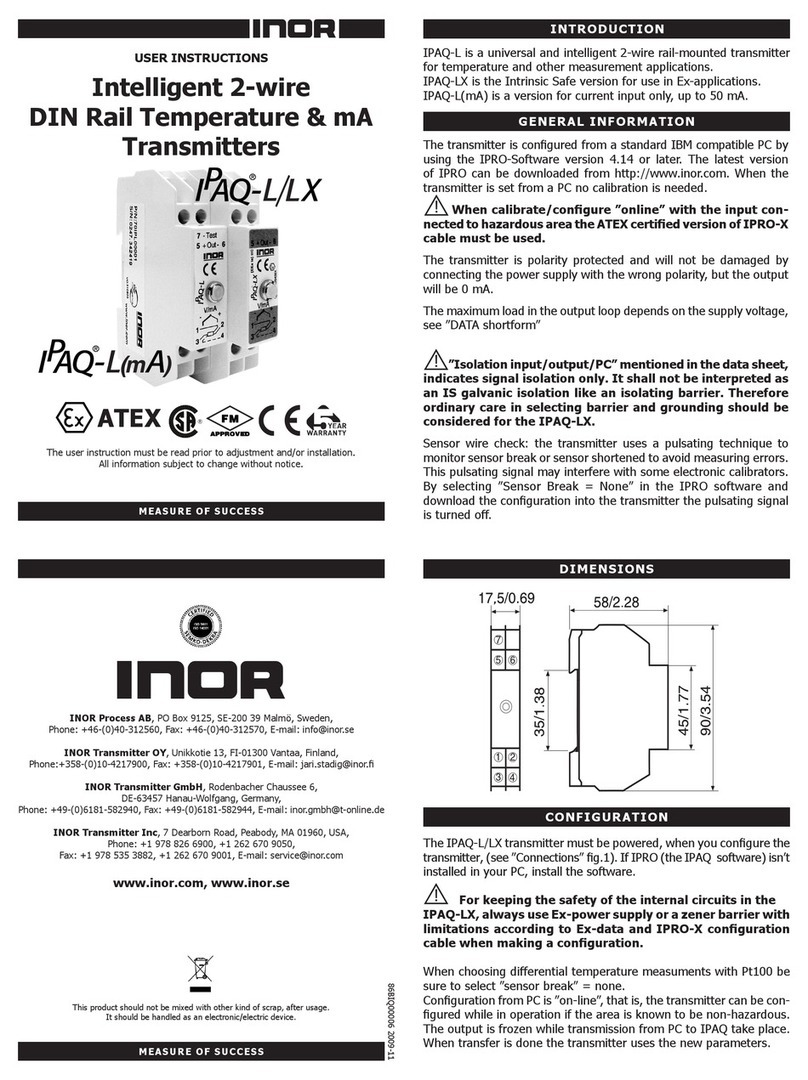

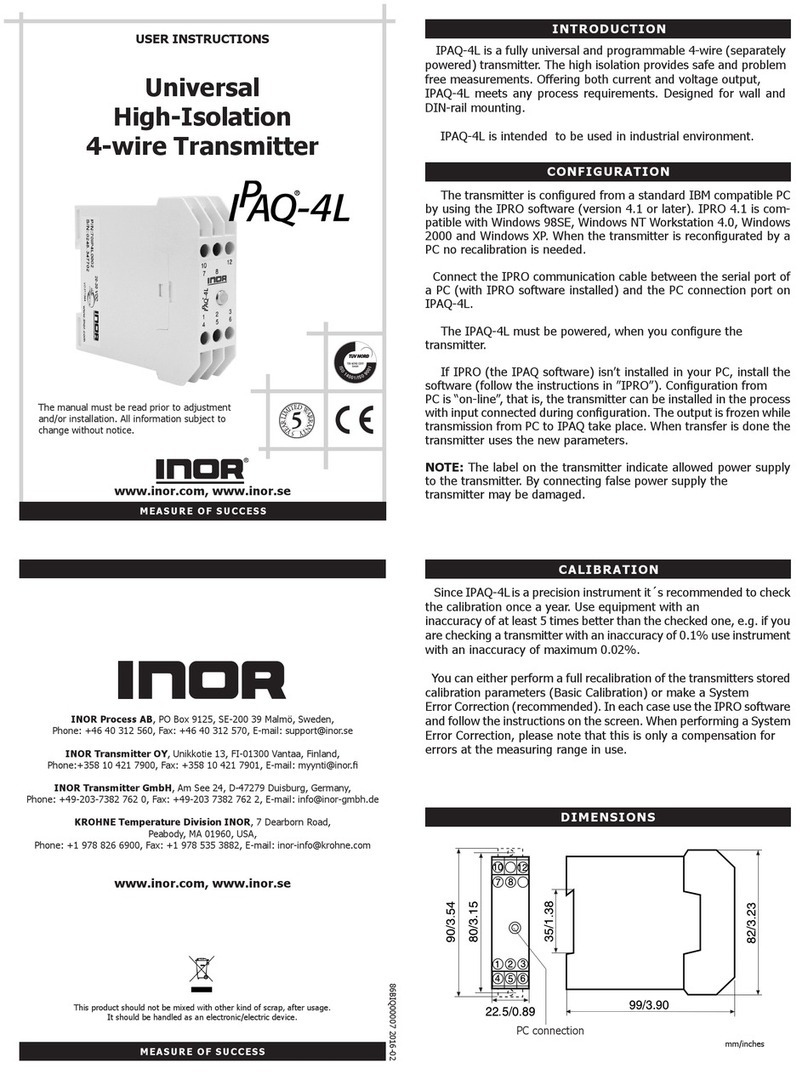

DIMENSIONS