SAFETY FUNCTION

4

9

IPAQ C520/R520

www.inor.com02/2019 - 86B520S001 - AD 520 SIL R1.4 en

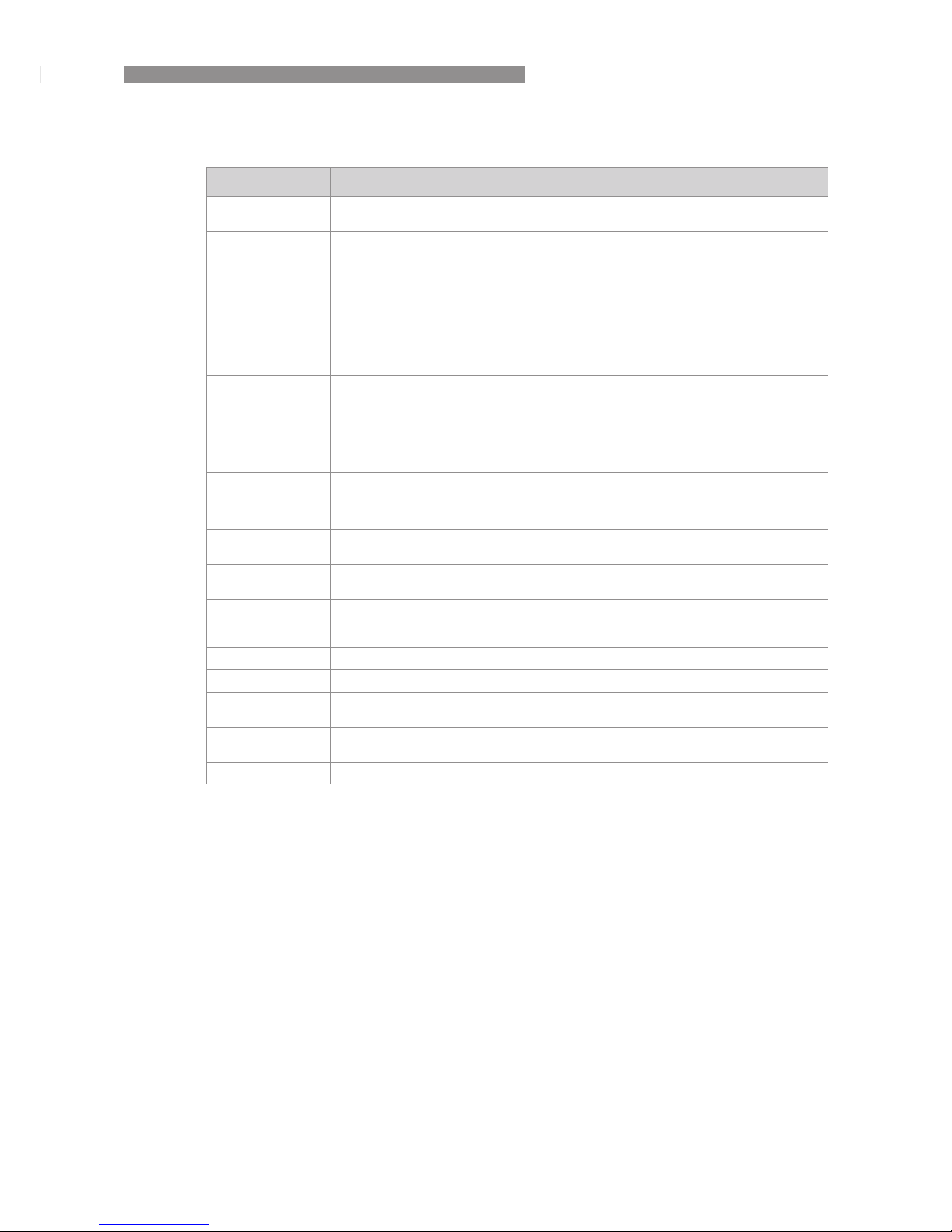

A software SIL-switch is available in the transmitter, handled by the PC-configuration software

ConSoft. It is password-protected by the same password that protects from change of

configuration. The SIL-switch can also be changed by HART communication, still password-

protected. The password may be changed either via ConSoft or via HART communications. It is

stored in the transmitter and it has to be accurate in order to download any changes to the

transmitter configuration. When the transmitter is shipped, the password default value is “0000”.

For SIL applications the password must be changed

For SIL applications the password must be changedFor SIL applications the password must be changed

For SIL applications the password must be changed to a user specific password in order to

prevent unintended change of configuration.

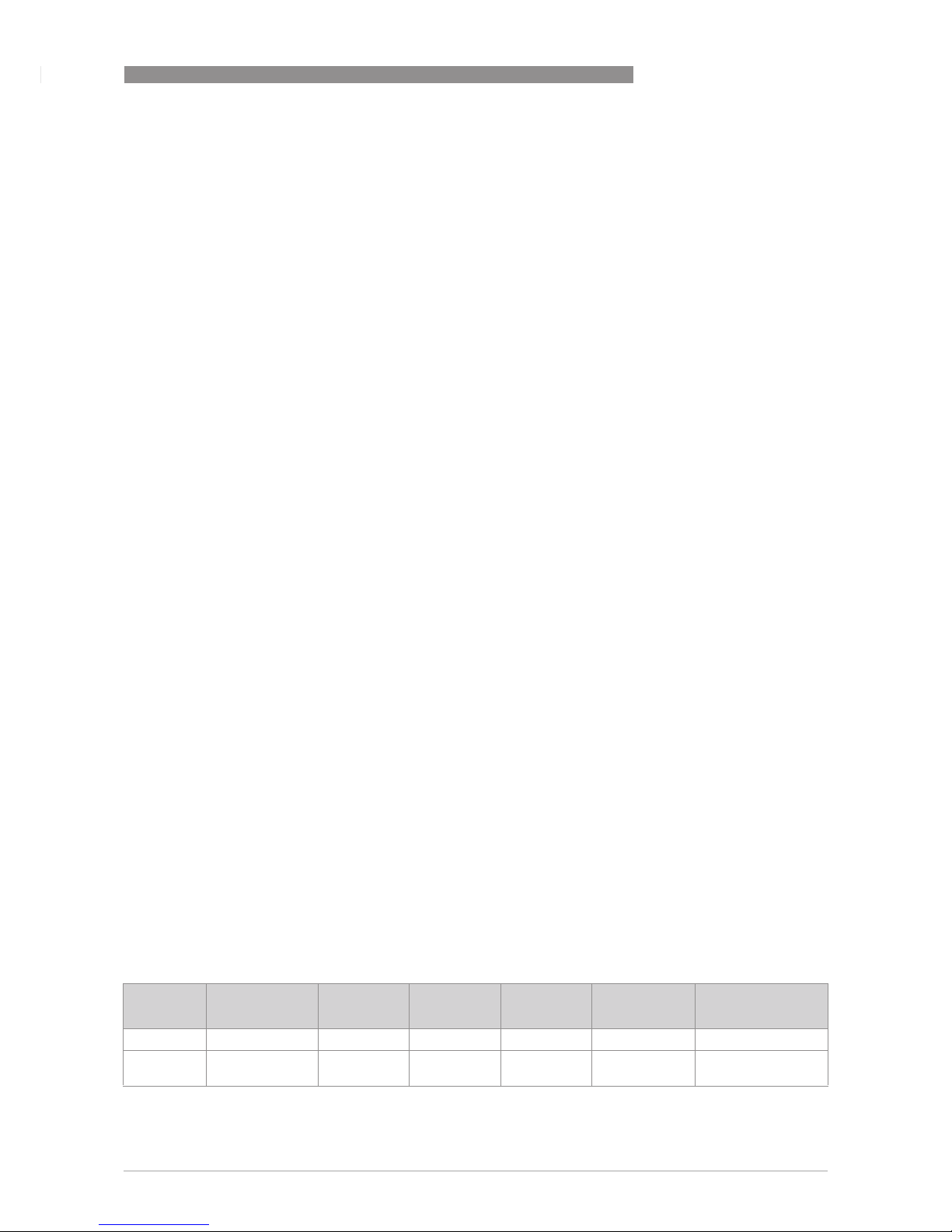

The following definitions of the failure are used during diagnostic calculations:

1For some system failures the alarm output will toggle between a high alarm level (≥21.0 mA)

and a low alarm level (≤3.6 mA). For some HW failures the alarm level will be high even though a

low level is configured and for some other HW failures the alarm will go low even though a high

level has been selected.

To prevent a safety system from restart due to the toggling output the system should be setup so

that once an alarm signal has occurred from the safety loop the system shouldn’t go back to

normal run automatically but only manual ("Restart Interlock").

2Transmitter errors = failures in the software or hardware detected by the diagnostics in the

transmitter.

3The sensor drift function is valid from SW-versions; IPM-SW 01.01.03 and OPM-SW 01.01.04

and hardware versions 5 and later, implemented in transmitters with serial number 1006.xxxxxx

or later. Serial number 1006.xxxxxx means manufactured week 6 in 2010 and this information is

found on the nameplate or it can be read from the transmitter via ConSoft. The software and

hardware versions can be read from the ConSoft software, tab "Device Information".

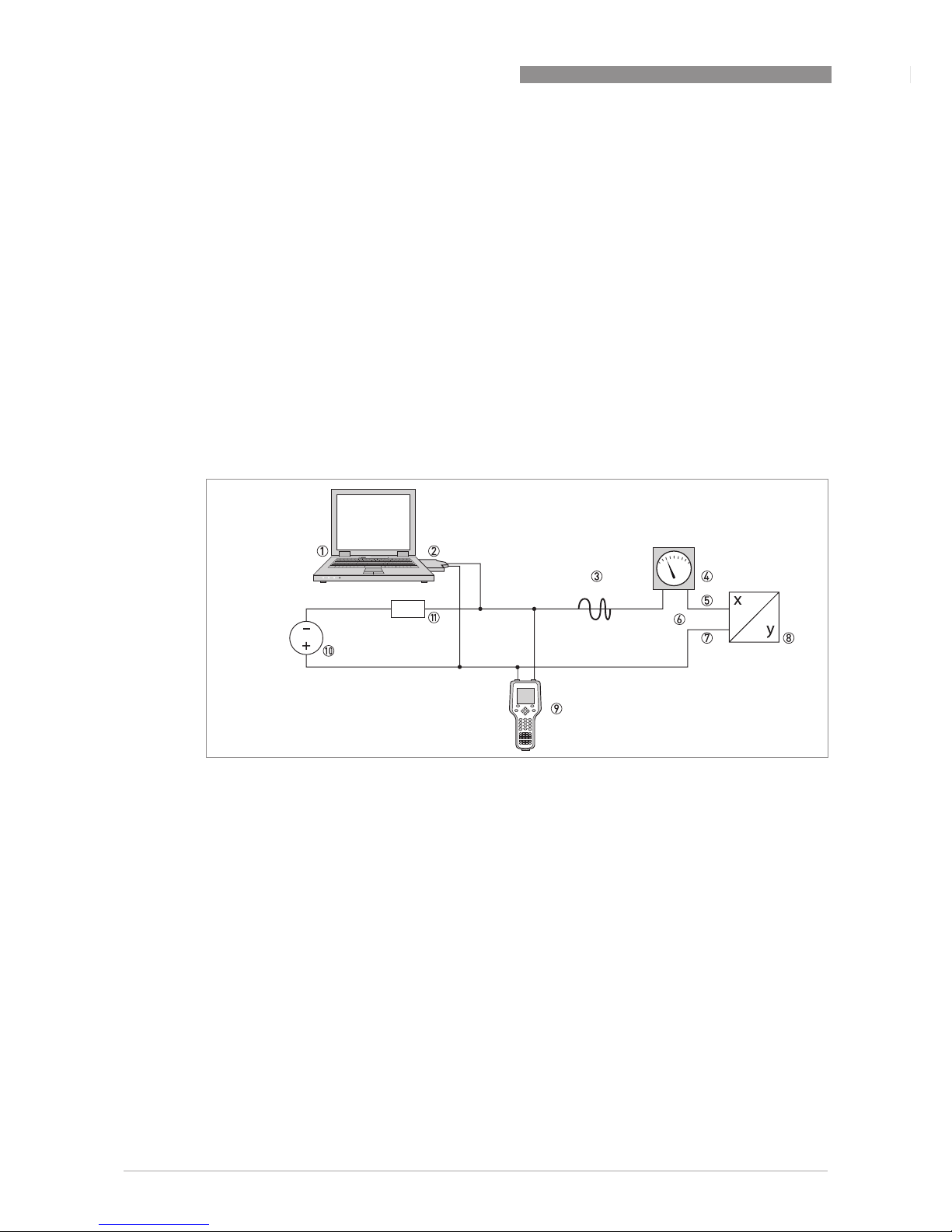

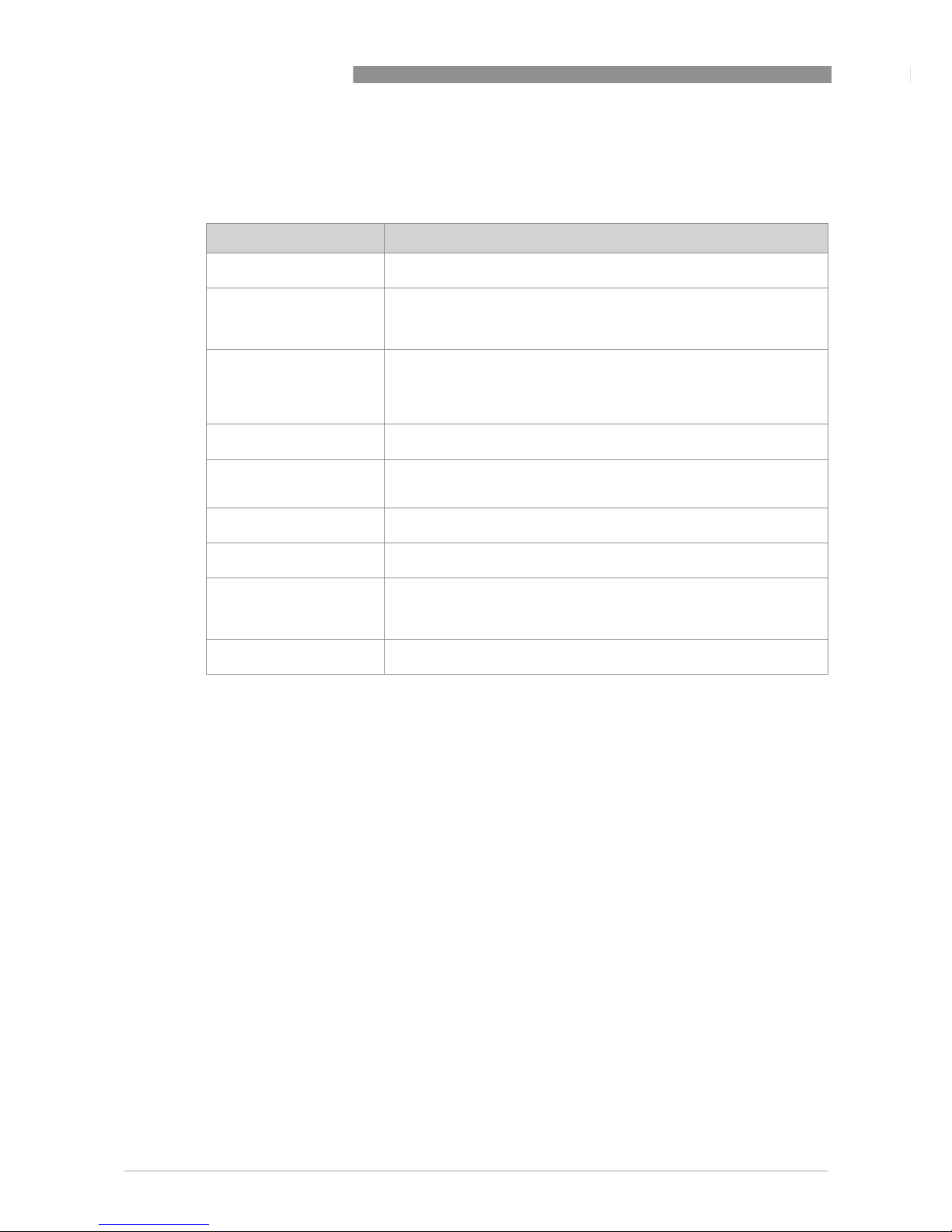

4.3 Redundancy

For the following configurations:

•2 x 2w RTD sensors

•2 x 3w RTD sensors

•2 x 4W RTD sensors (only valid for R520S/R520XS)

•2 x Thermocouple sensors

•1x Thermocouple sensor and 1 x 3w RTD sensor

•1x Thermocouple sensor and 1 x 4w RTD sensor (only valid for R520S/R520XS)

are either "Sensor drift monitoring" function or "Sensor backup" function selectable at a time.

Function Active/Not Active Output Alarm level 1

Sensor break Active 4...20 mA / 20...4 mA ≤3.6 mA / ≥21.0 mA

Sensor short Active 4...20 mA / 20...4 mA ≤3.6 mA / ≥21.0 mA

Low isolation Not active - -

Transmitter error 2Active 4...20 mA / 20...4 mA ≥21.0 mA

Sensor drift (dual

sensor needed) 3Active/Not Active

selectable 4...20 mA / 20...4 mA ≤3.6 mA / ≥21.0 mA