Insignia INS003 User manual

Other Insignia Shower Cabin manuals

Insignia

Insignia INS2000 User manual

Insignia

Insignia INS8059.1R User manual

Insignia

Insignia GT1057 User manual

Insignia

Insignia GT8720 User manual

Insignia

Insignia INS8058R User manual

Insignia

Insignia Monochrome Series User manual

Insignia

Insignia H88-842 User manual

Insignia

Insignia ES003 User manual

Insignia

Insignia INS0509 User manual

Insignia

Insignia INS3000 User manual

Insignia

Insignia INS1057.1 User manual

Insignia

Insignia INS5000R User manual

Insignia

Insignia GT9012 User manual

Insignia

Insignia GT8721 User manual

Insignia

Insignia GT003 User manual

Insignia

Insignia GT0509 User manual

Insignia

Insignia ES005 User manual

Insignia

Insignia INS9002L User manual

Insignia

Insignia GT002 User manual

Insignia

Insignia INS8721 User manual

Popular Shower Cabin manuals by other brands

agape

agape FLAT D E1P Instructions for installation

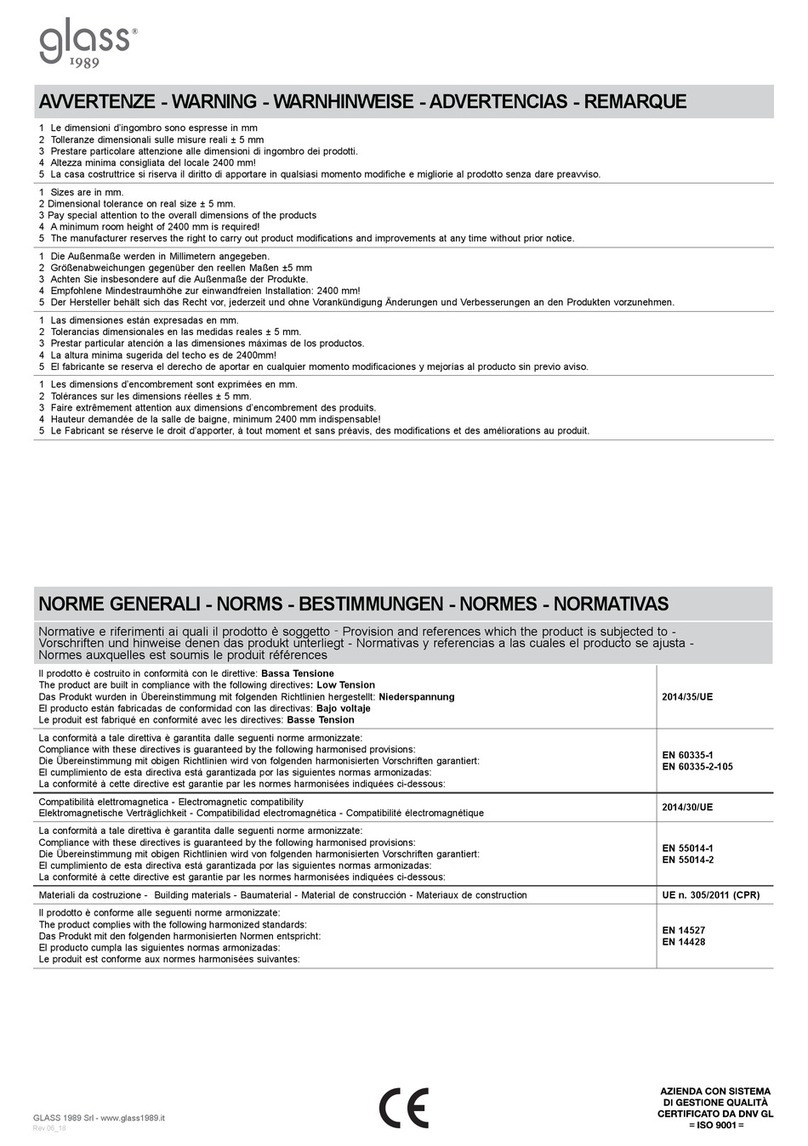

glass 1989

glass 1989 nonsolodoccia home 140/90 manual

AM.PM

AM.PM ADMIRE STEAM CABIN A Assembly instructions

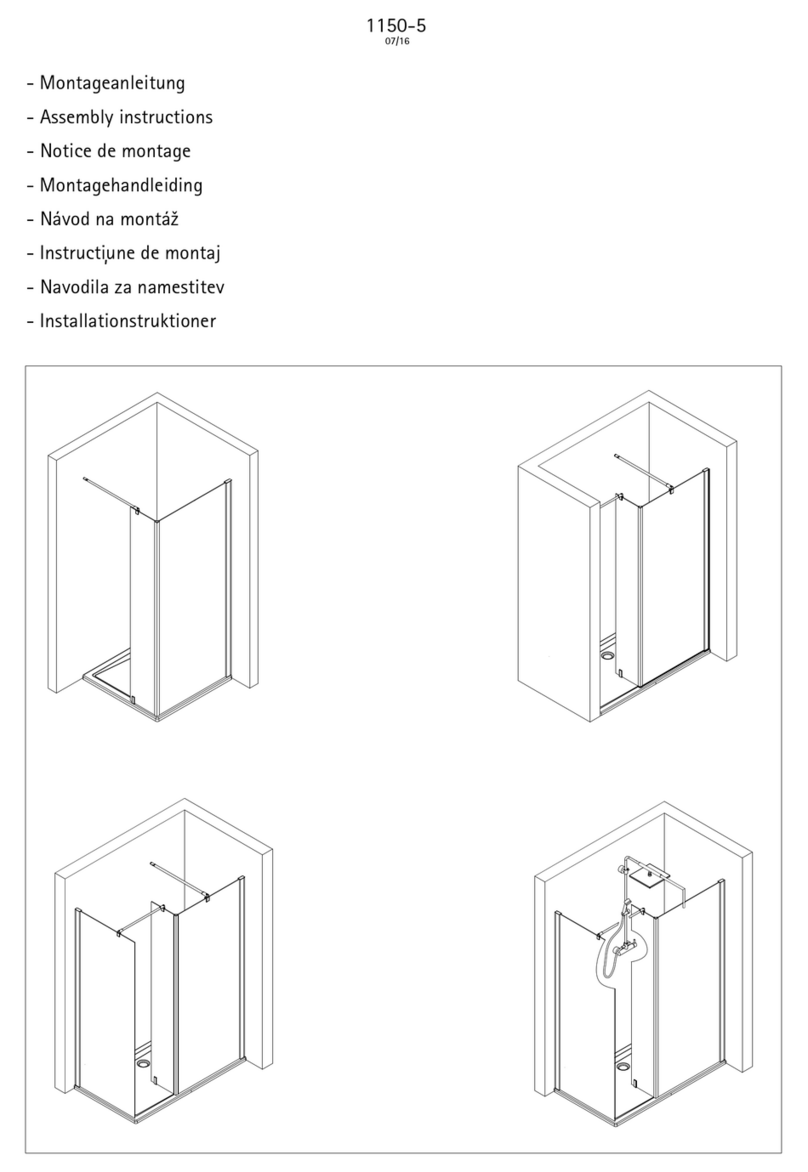

Schulte

Schulte MasterClass D1209030 Assembly instructions

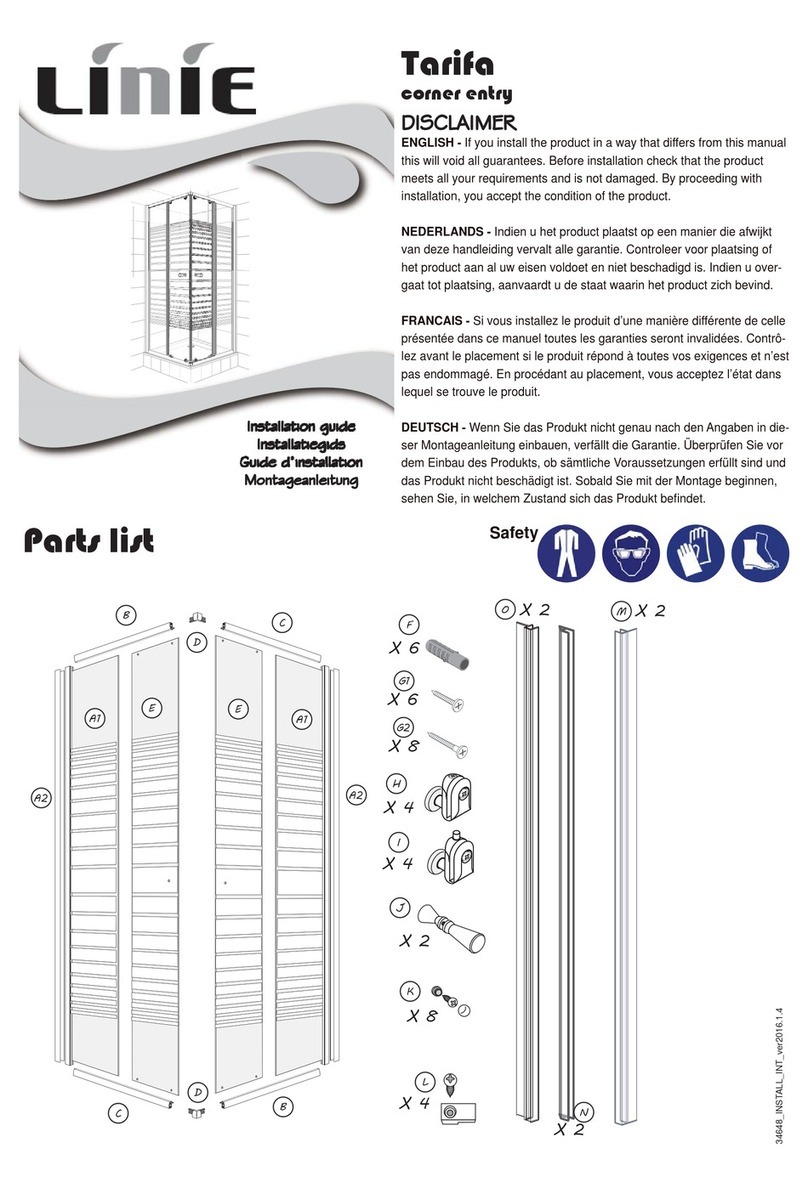

Linie

Linie Tarifa installation guide

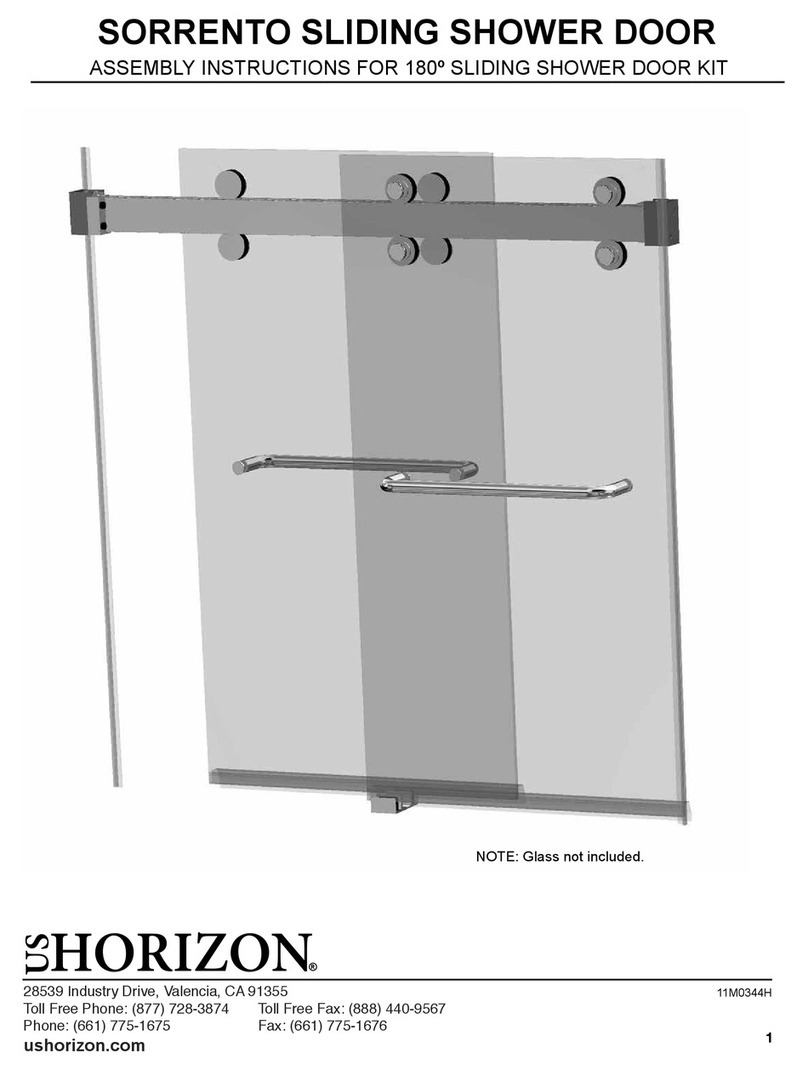

US HORIZON

US HORIZON SORRENTO Series Assembly instructions

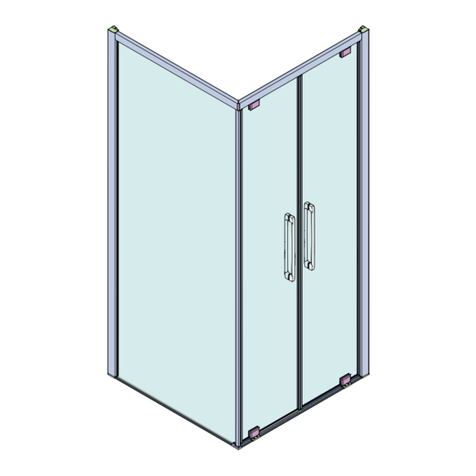

Arblu

Arblu PERSEO ANGOLO Q-R 2SL+1LF Assembling instructions

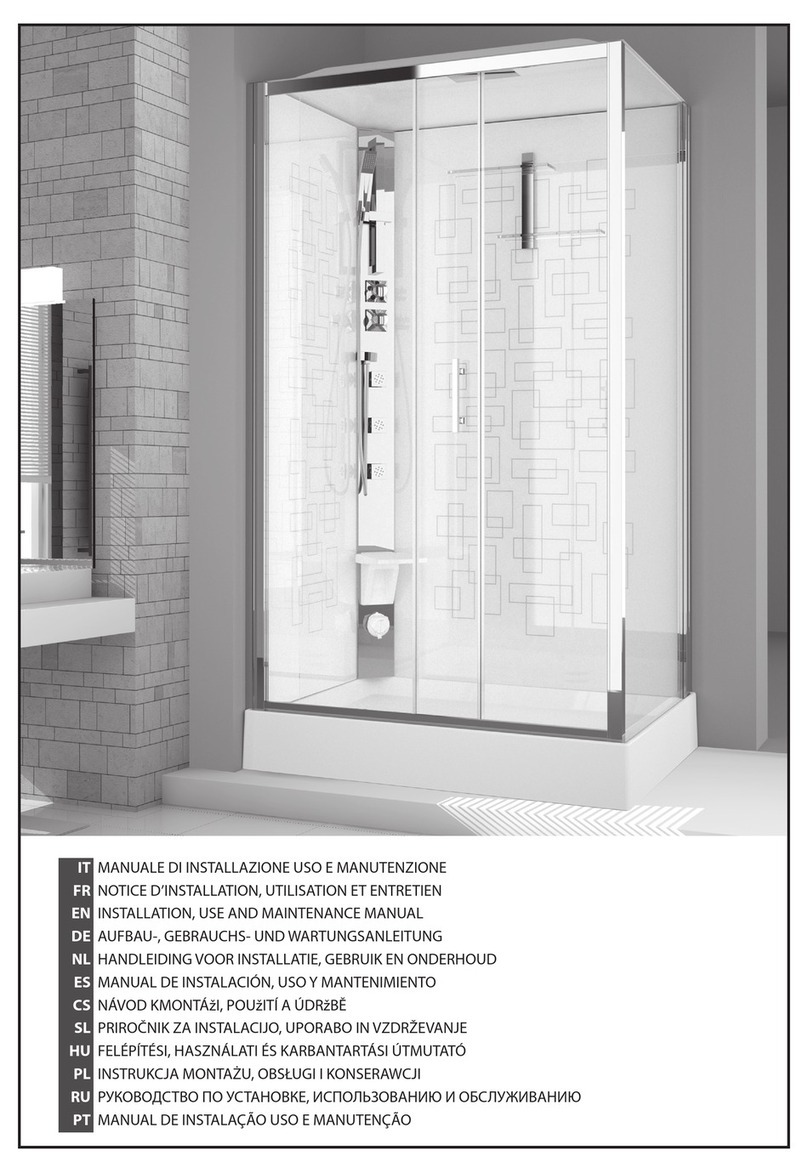

Novellini

Novellini R90 base p.80 Instructions for installation, use and maintenance manual

SANPLAST

SANPLAST KP1DJa/TX5b Installation instruction

Kohler

Kohler Sterling 2375 Series installation guide

ELEGANT

ELEGANT SPR870 quick start guide

Jacuzzi

Jacuzzi frame in2 installation manual