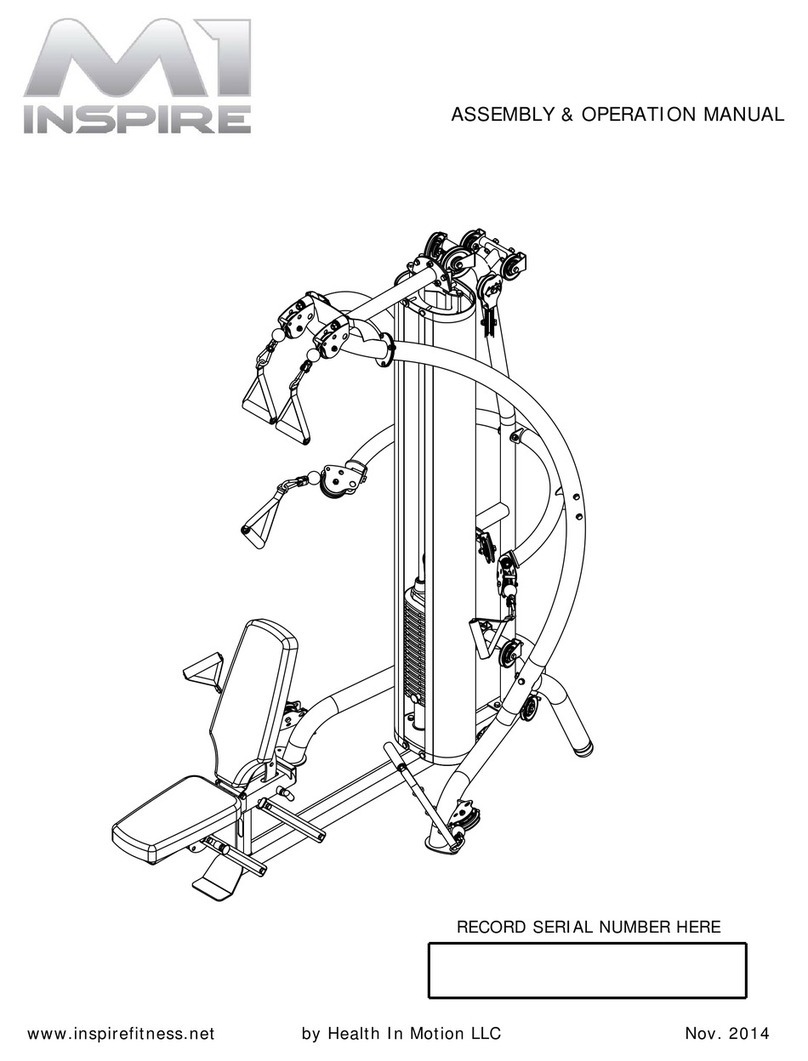

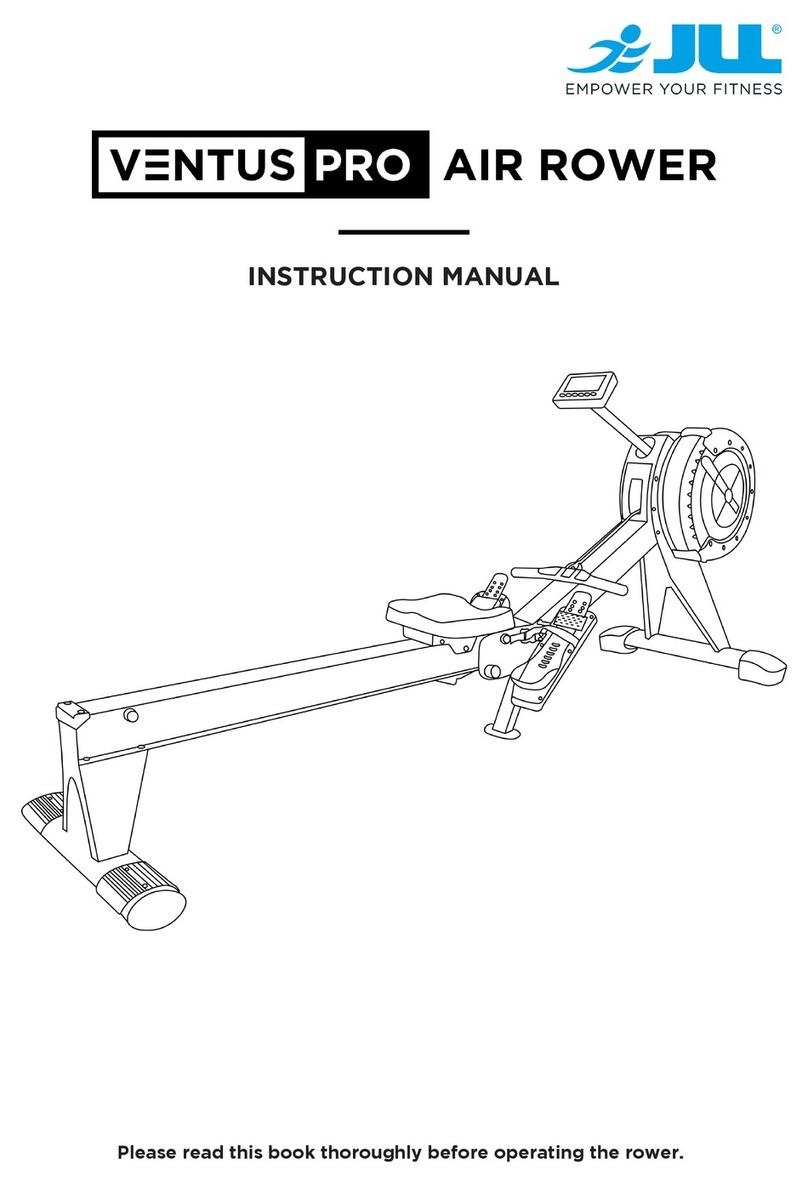

1Right Base 154 "D" Handle 2

2Left Base 155 Slider Adjustment Handle 2

3Rear Cross Brace 156 Pull-up Strap 1

4L Front Upright, Left 157 Ankle Strap 1

4R Front Upright, Right 158 Add-on Weight, 5 Lb 2

5Rear Upright 159 Upper Shroud Mount Bracket, Front 2

6Rear Pulley Mount 160 Upper Shroud Mount Bracket, Left 1

7Weight Bar 161 Upper Shroud Mount Bracket, Right 1

8Slider, Right 162 Upper Shroud Bracket 4

9Slider, Left 163 Rear Shroud Bracket 2

10 Linear Bearing Shaft 264 Lower Shroud Bracket 4

11 Spring 265 3 1/2" Pulley Assembly 4

12 Linear Bearing Slider, Right 166 Metal Shroud, Inner Left 1

13 Linear Bearing Slider, Left 167 Metal Shroud, Outer Left 1

14 Front Cross Brace 168 Metal Shroud, Inner Right 1

15 Top Beam, Right 169 Metal Shroud, Outer Right 1

16 Top Beam, Left 170 Fabric Shroud, Outer 2

17 Lat Beam Pivot 171 Fabric Shroud, Inner Narrow 2

18 Top Beam Plate Assembly, Left 172 Fabric shroud, Inner Wide 2

19 Top Beam Plate Assembly, Right 173 Fabric Shroud, Rear 2

20 Lat Beam 174 M12 Flat Washer 6

21 Pull-up Bar 175 Weight Stack Rubber Donut 4

22 Floating Pulley Assembly 476 Slider Rubber Donut 2

23 Top Weight Assembly 277 Spring Clip 8

24 Guide Rod 478 M10*120 Hex Bolt 6

25 Weight Plate 30 79 M10*80 Socket Head Cap Screw 2

26 Weight Stack Riser 480 M10*90 Hex Bolt 6

27 Top Weight Pulley Bracket Assy 281 M10*70 Hex Bolt 2

28 Weight Pin 282 M10*75 Hex Bolt 6

29 Swivel Pulley Assembly 283 M10*80 Hex Bolt 5

30 N/A 84 M8*16 Button Head Bolt 12

31 Cable End Bracket 285 M12*85 Hex Bolt 2

32 Lower Cable 286 M10*25 Hex Bolt 2

33 Upper Cable 287 M10*175 Hex Bolt 1

34 Rear Cable 288 M12*30 Hex Bolt 2

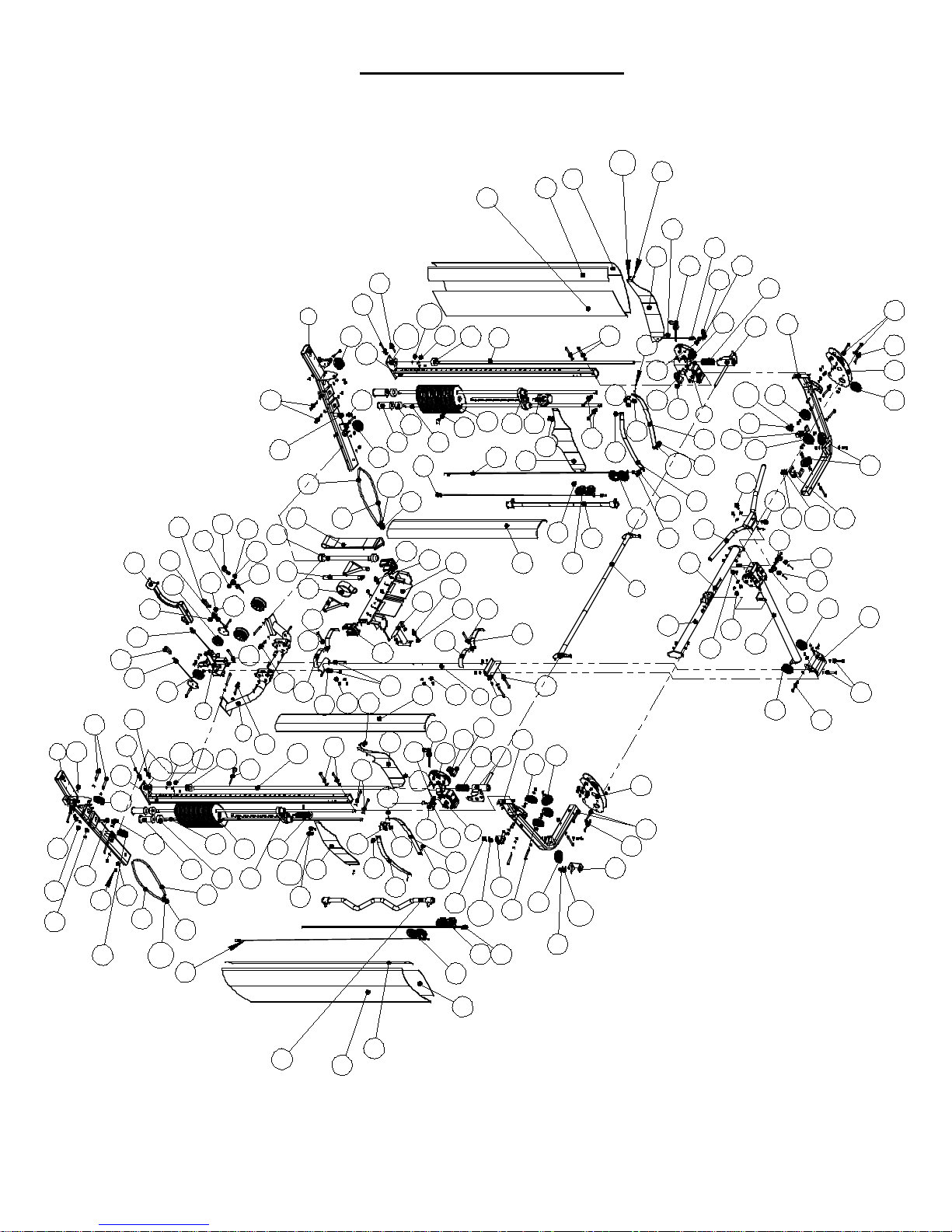

35 Guide Cable Assy, Long 289 M10*85 Hex Bolt 7

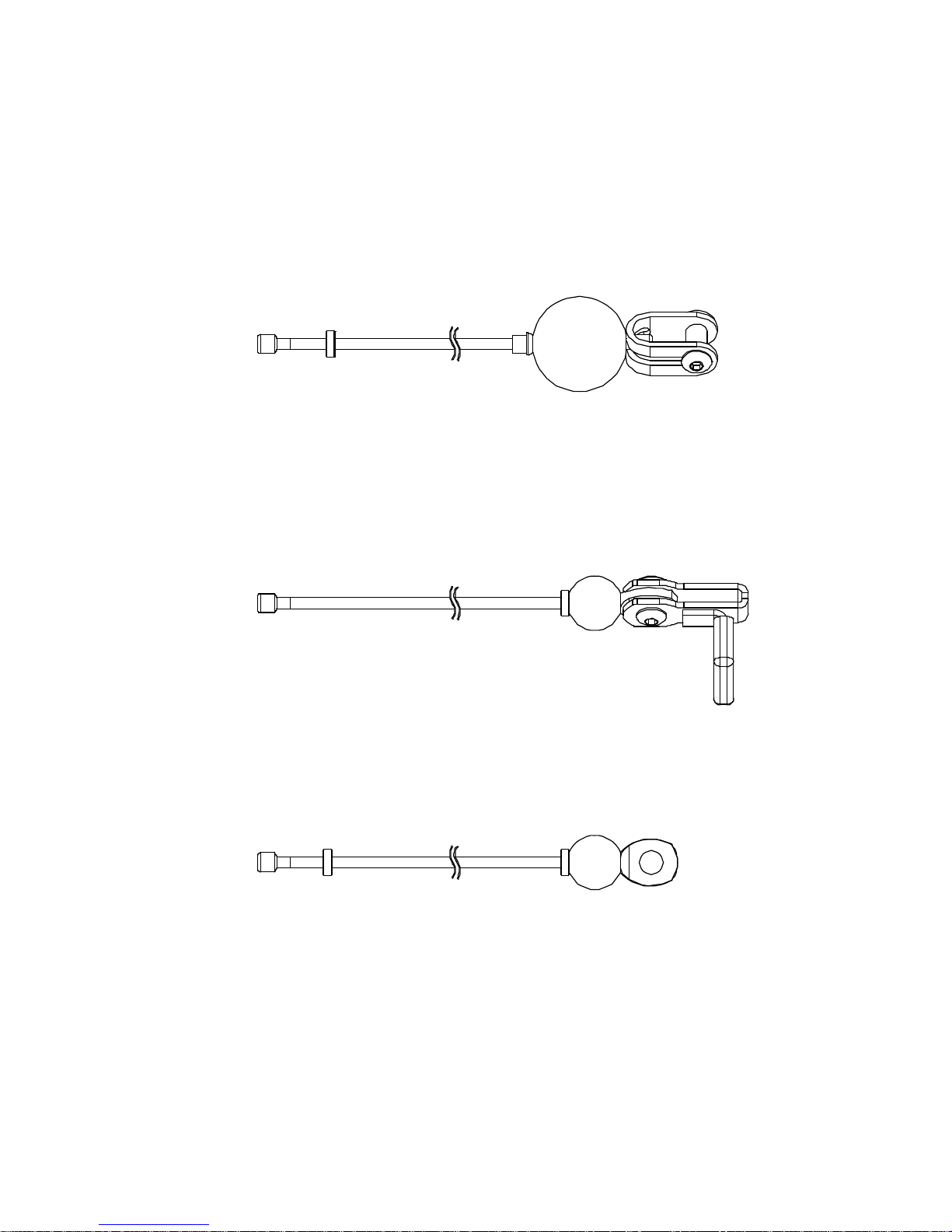

36 Guide Cable Assy, Short 290 N/A

37 Slotted Cable Adjustment Bolt 291 M10*95 Hex Bolt 2

38 Flat Head Nut, M6*13 292 M10*115 Hex Bolt 4

39 M6*8 Button Head Bolt 293 M12 Locknut 4

40 M6*15 Button Head Bolt 494 M10*20 Button Head Bolt 2

41 Flat Head Nut, M6*25.5 495 M6*12 Button Head Bolt 28

42 "U" Bracket Cable End 496 M5*10 Philips Head Screw 4

43 Cable Ball 497 M10 Flat Washer 74

44 M5*8 Socket Head Cap Screw 298 M10 Locknut 45

45 M12 Flange Nut 299 M10 Curved Washer 14

46 Bench Stop 1100 M8 Flat Washer 12

47 Book/Accessory Rack Support 1101 M6 Flat Washer 28

48 Book/Accessory Rack 1102 M5 Flat Washer 4

49 Accessory Hanger Bracket 2103 4mm Allen Wrench 1

50 Revolving Straight Bar 1104 5mm Allen Wrench 2

51 Revolving EZ Curl Bar 1105 6mm Allen Wrench 1

52 Sports Handle 1106 8mm Allen Wrench 1

53 Exercise Rope 1107 M6*5 Setscrew 4