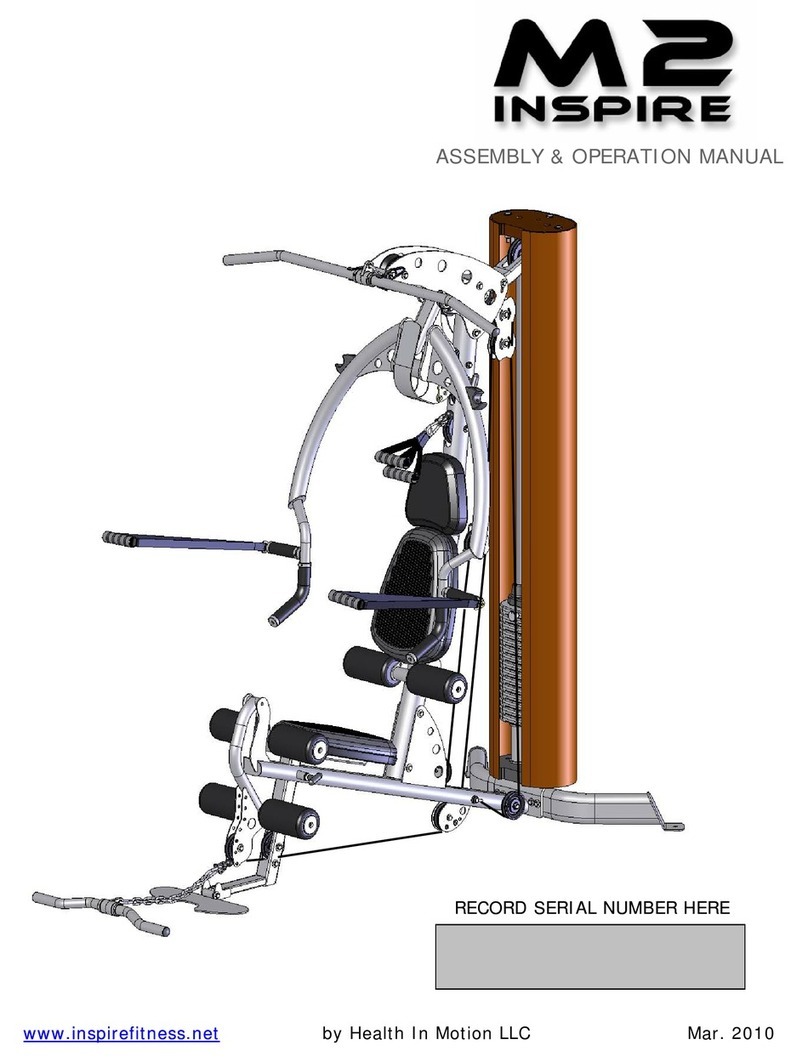

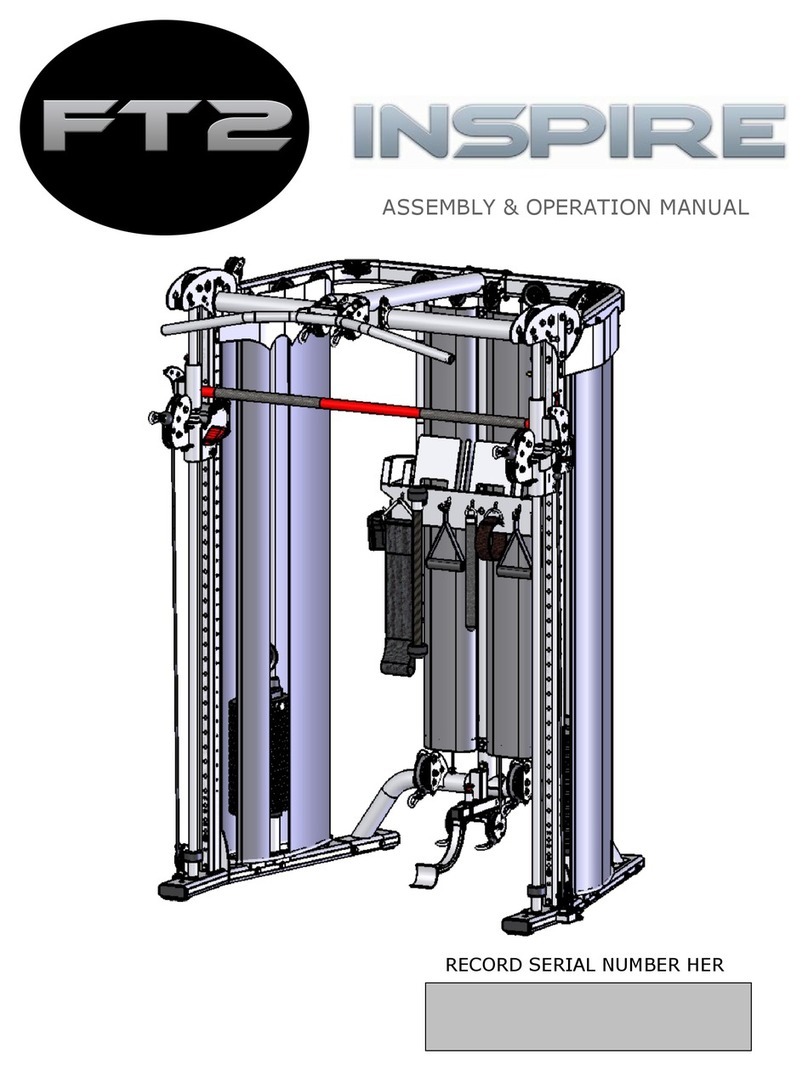

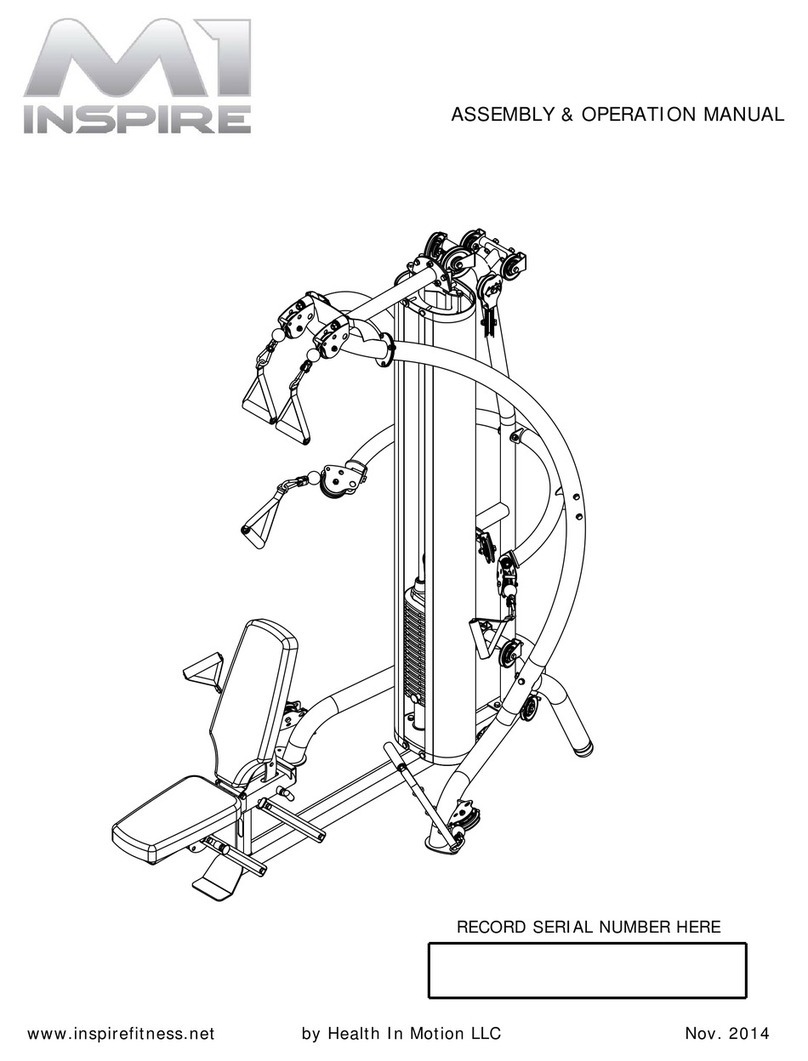

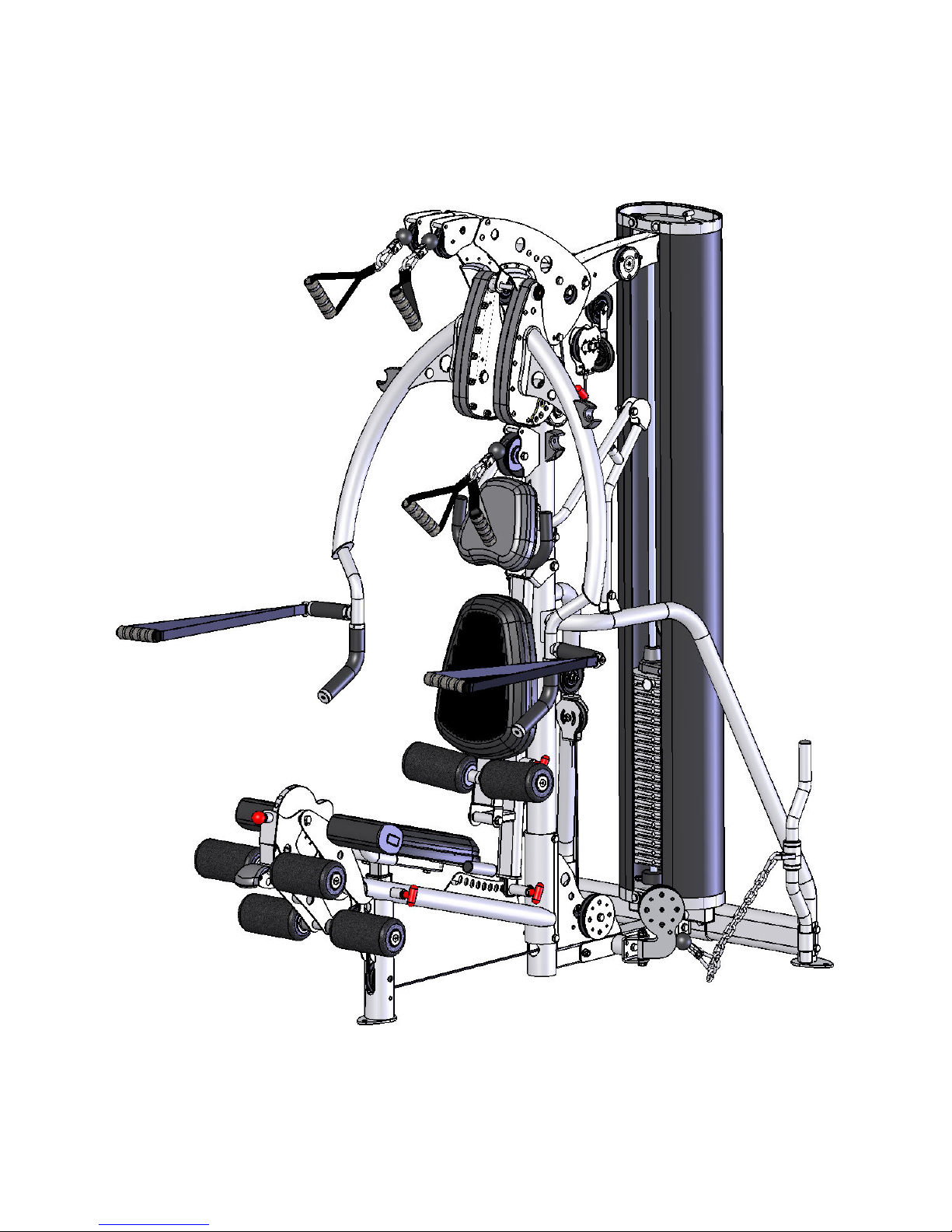

CONGRATULATIONS… You’ve just taken the first step to a healthier

and stronger body. This home gym by Inspire Fitness offers the key to

unlocking your body’s potential. Regular strength training on a home gym

has been shown to deliver a host of benefits including: increased muscle

tone, decreased body fat, improved energy levels, a reduction in stress, and

improved cardiac output. Once again, congratulations, you are on your way

to improving your self image, overall health and quality of life.

BEFORE ASSEMBLING YOUR HOME GYM

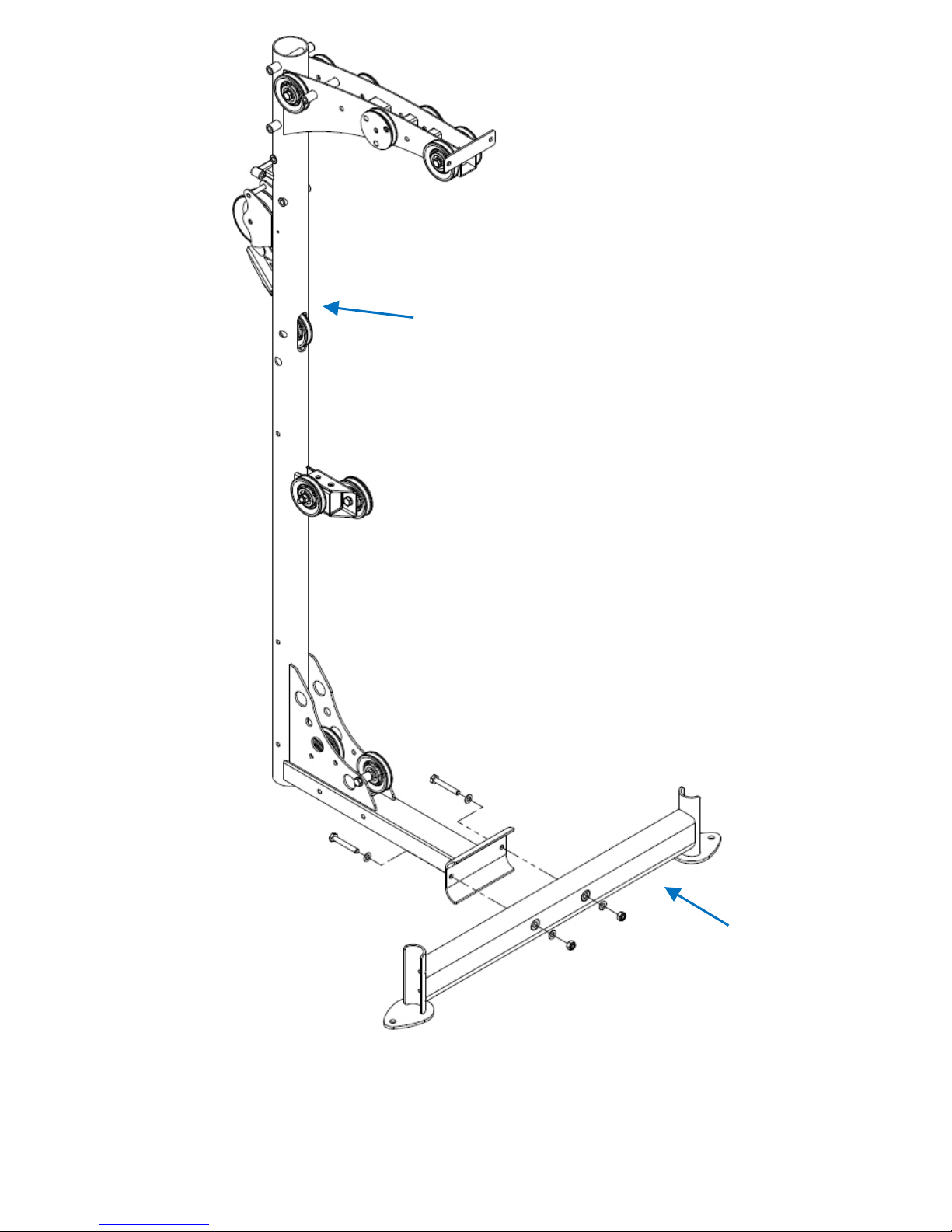

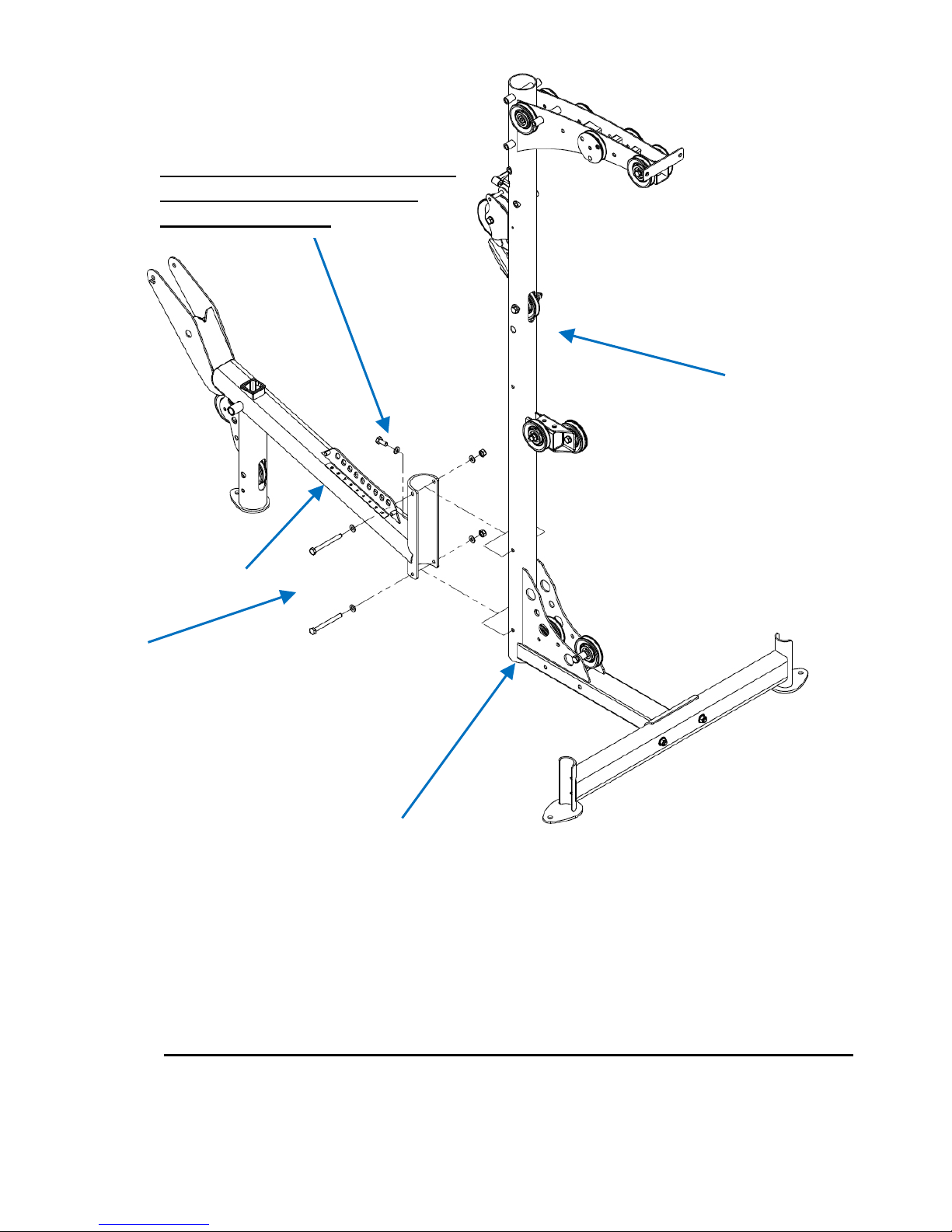

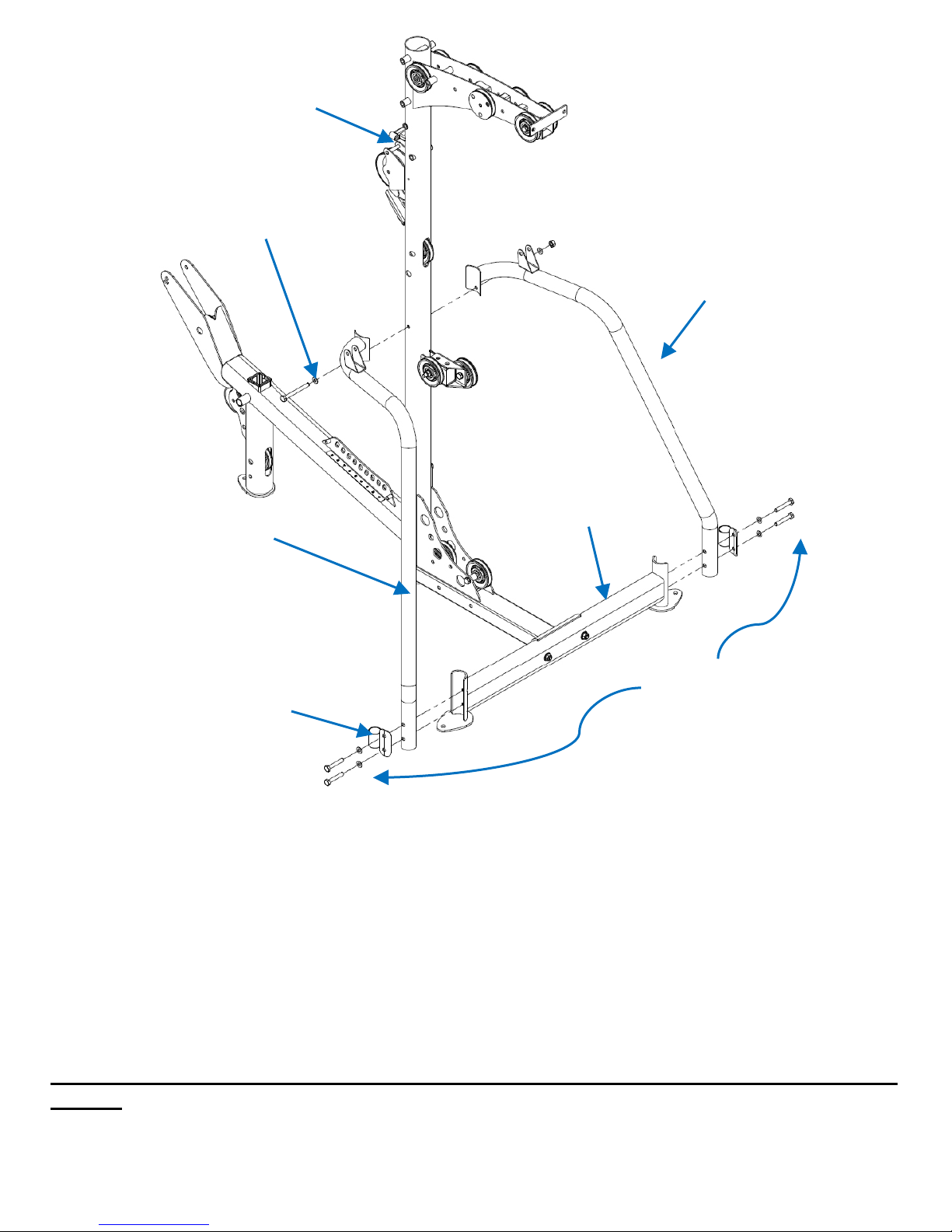

IMPORTANT: Read this entire manual before attempting to build or use

this machine. This manual contains step by step instructions for proper

assembly.

Use the parts list included in this manual to verify that all parts are

accounted for before assembly. If any parts are missing, contact the retailer

of this home gym for replacement parts. Or, call Inspire at 877-738-1729.

Make sure that adequate room has been cleared before attempting to build

your home gym. A rubber mat is recommended for use under your home

gym to protect wood flooring or carpeting from damage during assembly

and usage.

This home gym is intended for indoor use only. In addition, garages and

screened in porches are not recommended due to high humidity or dust.

Certain parts including guide rods can form rust in a humid environment,

resulting in impaired function.

Service of your home gym should only be preformed by an authorized

Inspire Fitness retailer. Service preformed by anyone else can result in loss

of warranty. If you need help finding an authorized retailer, please contact

us directly:

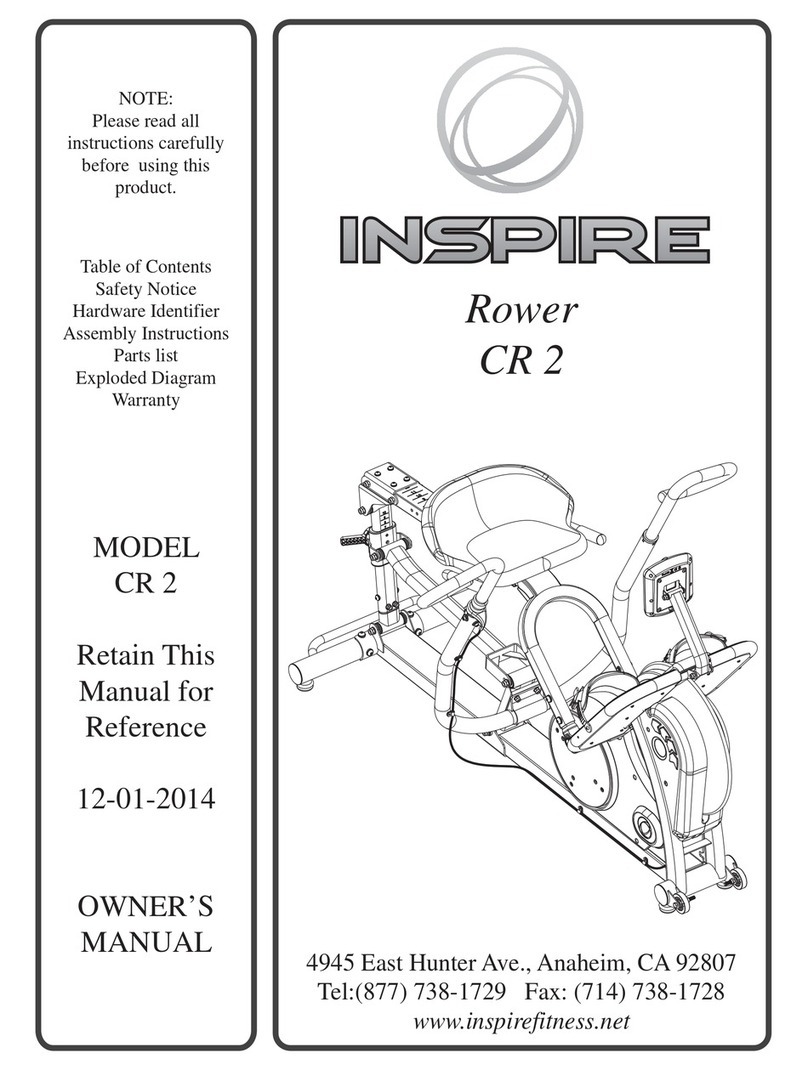

Inspire Fitness

4945 East Hunter Avenue

Anaheim, CA 92807

Ph: 877-738-1729

Fx: 714-738-1728

www.inspirefitness.net