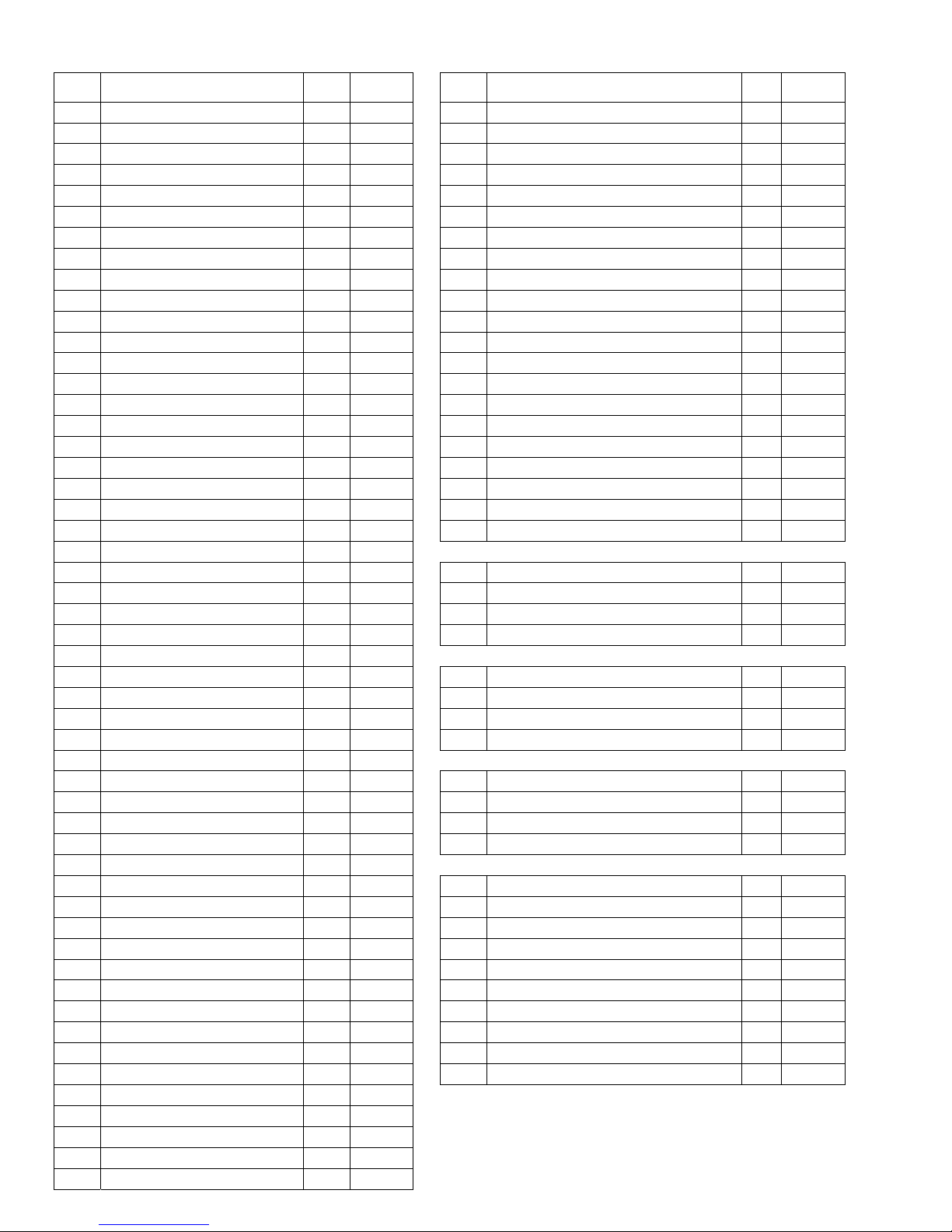

PARTS & HARDWARE LIST

Item Parts Description Qty Qty

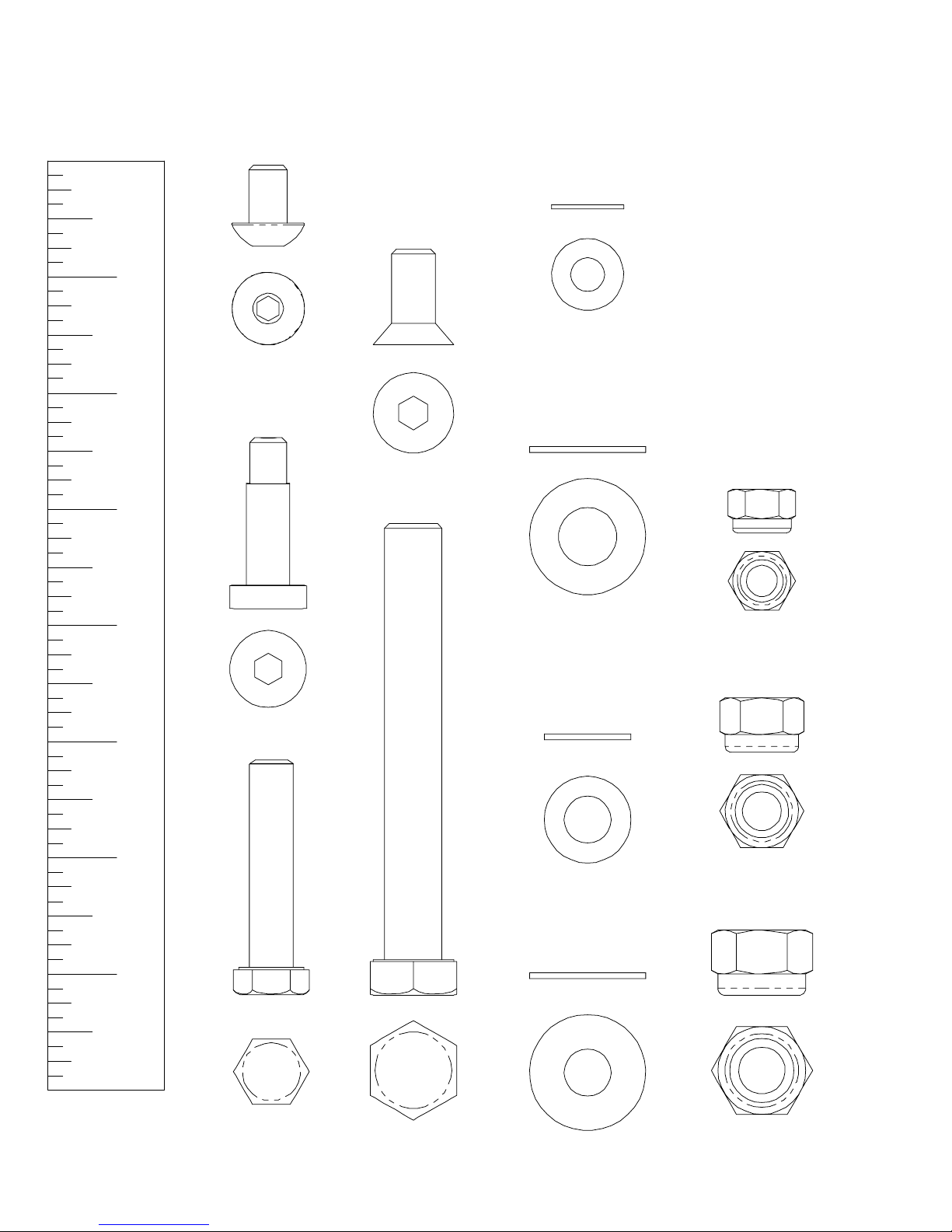

Rec'd Item Hardware Description Qty

Qty

Rec'd

1 Main Upright 1 1 Bolt, 1/4-20 x 3/8" L (Phillips head) 1

2 Rear Base 1 2 Bolt, 5/16-18 x 1 1/4” L (Shoulder) 3

3 Seat Base Frame 1 3 Bolt, 3/8x16 x 1" L (Flat Head) 6

4 Upright Support, Right 1 4 Bolt, 3/8-16 x 1/2" L (Button Head) 2

5 Upright Support, Left 1 5 Bolt, 3/8-16 x 1" L 10

6 Ab Frame Assy 1 6 Bolt, 3/8-16 x 1 3/4" L 9

7 Ab Frame Arms 2 7 Bolt, 3/8-16 x 2" L 11

8 Backpad Support Frame 1 8 Bolt, 3/8-16 x 2 1/4" L 4

9 Backpad Mount 1 9 Bolt, 3/8-16 x 2 1/2" L 1

10 Seat Stem Assy 1 10 Bolt, 3/8-16 x 2 3/4" L 2

11 Top Beam Plate 2 11 Bolt, 3/8-16 x 3" L 8

12 Press Arm Mount 1 12 Bolt, 3/8-16 x 3 1/4" L 1

13 Press Arm Cover Plate 1 13 Bolt, 3/8-16 x 3 3/4" L 6

14 Press Arm Bearing Assembly 2 14 Bolt, 3/8-16 x 4" L 6

15 Press Arm Assembly 1 15 Bolt, 3/8-16 x 4 1/4" L 5

16 Leg Extension Assy 1 16 Bolt, 3/8-16 x 4 3/4" L 1

17 Leg Extension Cam 1 17 Bolt, 1/2-13 x 3 1/2" L 1

18 Swivel Pulley Mount 1 18 Bolt, 1/2-13 x 3 3/4" L 1

19 Swivel Pulley Bracket 1 19 Bolt, 1/2-13 x 4" L 1

20 Lower Guide Rod Mount 1 20 Bolt, 1/2-13 x 4 1/4" L 1

21 Lat Bar Holder 2 21 Bolt, 1/2-13 x 6" L 1

22 Guide Rod 2

23 Shroud Plate 1 22 1/4" Washer 1

24 Shroud Plate Assembly 1 23 3/8" Washer 101

25 Floating Pulley Plate 2 24 3/8" Washer, small OD 8

26 Floating Pulley Bracket 1 25 1/2" Washer 9

27 Floating Pulley Bracket Assy 1

28 Top Weight/Selector Stem 1 26 5/16-18 Locknut 3

29 Weight Stack Number 1 27 3/8-16 Locknut 50

30 Rubber Donut 2 28 1/2-13 Locknut 4

31 Covered Foam Roller 4 29 1/2-13 Thin Locknut 1

32 Roller Pad with Tube Insert 2

33 Thigh Pads 2 30 Spacer Tube, 3" Long 1

34 Large Plastic Washer 4 31 Step Spacer, 1" Long 10

35 Seat Base 2 32 Barrel Spacer, 1" Long 3

36 Head Pad 1 33 Barrel Spacer, 5/8" Long 2

37 Upper Cable 1

38 Middle Cable 1 34 Aluminum Endcaps 6

39 Lower Cable 1 35 Cable Adapter 2

40 Leg Extension Cable 1 36 Spring Clip 4

41 Revolving Aluminum Lat Bar 1 37 Chain 1

42 Revolving Aluminum Curl Bar 1 38 Weight Pin 1

43 D handle/Ab Strap 2 39 4 mm Wrench 1

44 Ankle Strap 1 40 6 mm Wrench 1

45 Guide Rod Lube 2 41 Cable Ball 3

46 Touch-up Paint 2 42 “U” Bracket Cable End 3

47 Wall Chart 1 43 Plastic Spacer Tube 2

48 Curl Bar Holder 1

49 Reinforcement Plate 1

50 3 1/2" Pulley 20

51 4 1/2" Pulley 2

52 4 1/2" Wide Pulley 2

PAGE 2