ISEKI TRACTORS

3

LOCK/UNLOCK DOORS .................................... 57

REAR WINDOW ................................................. 58

ROOF HATCH..................................................... 59

CORNERWINDOWS .......................................... 60

ROOMLAMP ....................................................... 60

WORKLIGHTS.................................................... 61

WIPER AND WASHER SWITCH ........................ 62

WASHER RESERVOIR ...................................... 63

POWER OUTLET SUPPLY................................. 64

CIGAR LIGHTER ................................................ 65

ASHTRAY ........................................................... 65

DRINK HOLDER................................................. 65

SUN VISOR ........................................................ 66

TOOL BOX.......................................................... 66

FREE BOX.......................................................... 66

AIR CONDITIONER OPERATION...................... 67

AIR VENT SWITCH ............................................ 67

TEMPERATURE ADJUSTMENT SWITCH ......... 67

AIR CONDITIONER SWITCH............................. 67

FAN SPEED CONTROL SWITCH ...................... 68

VENTILATION CONTROL SWITCH ................... 68

AIR VENT............................................................ 68

AIR-CONDITIONING and

DEHUMIDIFICATION.......................................... 68

HEATER.............................................................. 69

HEATER and DEHUMIDIFICATION ................... 69

DEFROSTER...................................................... 69

VENTILATION CONTROL SWITCH ................... 70

WHEN NOT USING AIR CONDITIONER ........... 70

7. LUBRICATION & PERIODIC MAINTENANCE ... 71

SPECIFICATIONS & CAPACITIES..................... 71

Engine Oil ...................................................... 71

Engine Coolant .............................................. 71

Fuel Tank ....................................................... 71

Transmission & Differential Housing

(Including Hydraulic System) ........................ 71

Front Axle....................................................... 71

Grease Fittings .............................................. 71

LUBRICATION/FILL POINTS.............................. 72

PERIODIC INSPECTION AND MAINTENANCE

TABLE ................................................................. 73

Removing/Reinstalling Side Cover ................ 75

Removing/Reinstalling Front Grille ................ 75

LUBRICATION DETAILS .................................... 76

Grease Fittings .............................................. 76

Engine Oil & Filter.......................................... 76

Transmission Oil & Filters.............................. 77

Checking/Replenishing Coolant..................... 79

Flushing Radiator / Replacing Coolant .......... 80

Use of Anti-Freeze......................................... 81

Cleaning of Radiator...................................... 81

Cleaning Air Cleaner / Vacuator Valve .......... 83

Use the following procedure to clean the

filter element: ................................................. 83

When there is dry dust................................... 83

When there is moist dirt or oil ........................ 83

FUEL SYSTEM ................................................... 84

Fuel Filter....................................................... 84

Replacing Fuel Filter Cartridge...................... 84

Inspecting Fuel Hose..................................... 84

Air-Bleeding Fuel System .............................. 84

Fuel Tank Filler Cap....................................... 84

ELECTRICAL SYSTEM ...................................... 85

Battery ........................................................... 85

Starting Switches .......................................... 87

Safety Switches ............................................. 87

Wiring / Fuse Arrangement............................ 87

Fuse Location ................................................ 88

Slow-Blow Fuse............................................. 89

CLUTCH FREE-PLAY ADJUSTMENT................ 91

BRAKE ADJUSTMENT....................................... 91

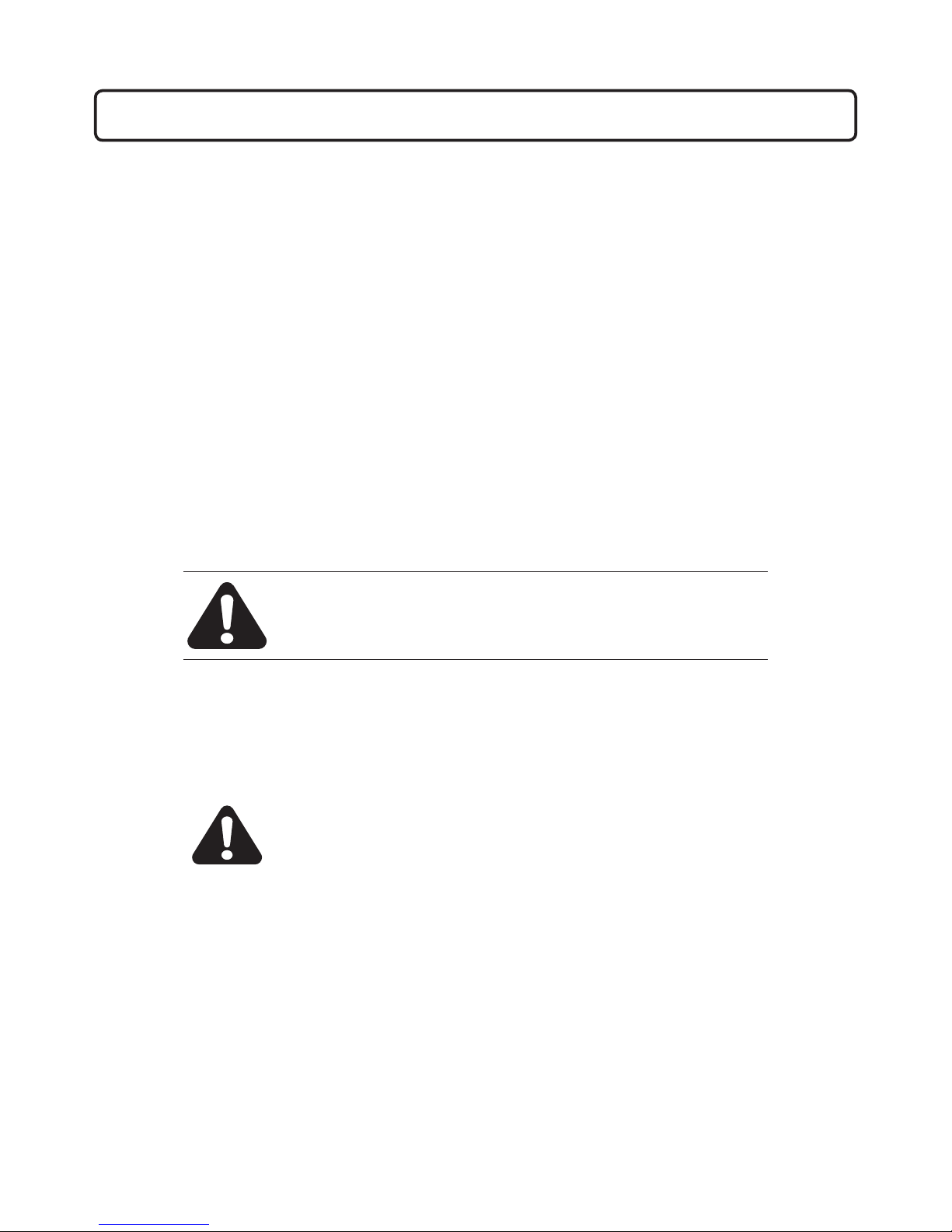

WHEELS & TIRES .............................................. 92

Tire Inflation Pressures.................................. 92

Wheel Bolt Torque ......................................... 92

Front Wheel Alignment .................................. 92

Steering Free-Play......................................... 93

Front Axle End-Float...................................... 93

TORQUE CHART................................................ 93

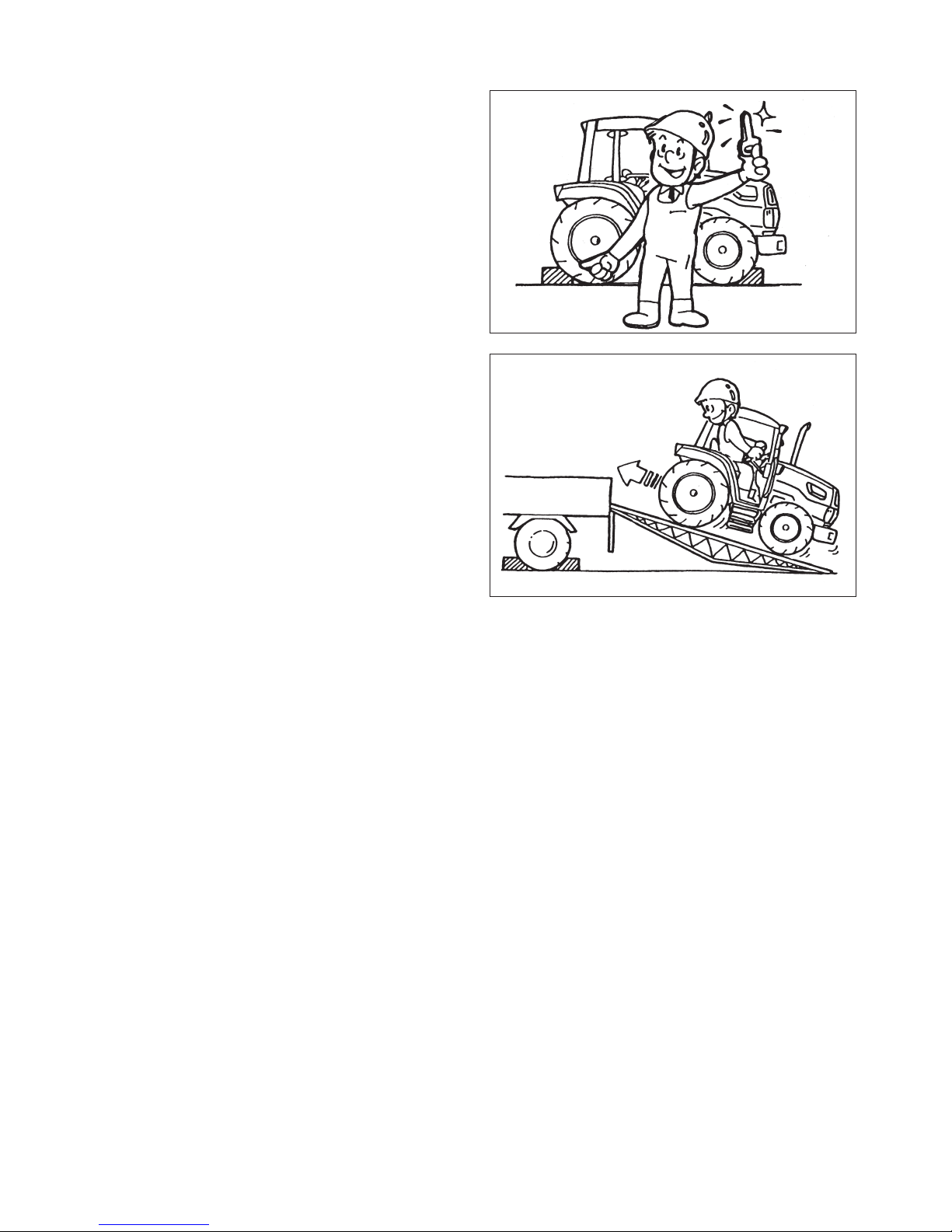

STORAGE........................................................... 94

8. TROUBLESHOOTING......................................... 96

ENGINE .............................................................. 96

CLUTCH.............................................................. 97

BRAKES.............................................................. 97

SHIFT LEVERS................................................... 98

POWER TAKE-OFF (PTO) ................................. 98

STEERING SYSTEM.......................................... 98

HYDRAULIC SYSTEM........................................ 99

ELECTRICAL SYSTEM ...................................... 100

CABIN ................................................................. 100

AIR CONDITIONER............................................ 101

INSTRUMENT PANEL ........................................ 101

DIGITAL PANEL .................................................. 102

9. DIGITAL PANEL CONTENTS.............................. 103

Normal Display .............................................. 103

Attention Display............................................ 104

Service Interval.............................................. 104

Gear Shift Error ............................................. 104

10. SPECIFICATIONS.............................................. 105

ENGINE .............................................................. 105

TRANSMISSION................................................. 105

POWER TAKE OFF (PTO).................................. 105

HYDRAULIC SYSTEM........................................ 105

ELECTRICAL SYSTEM ...................................... 106

CAPACITIES ....................................................... 106

TREAD WIDTH SETTING................................... 106