Table of Contents

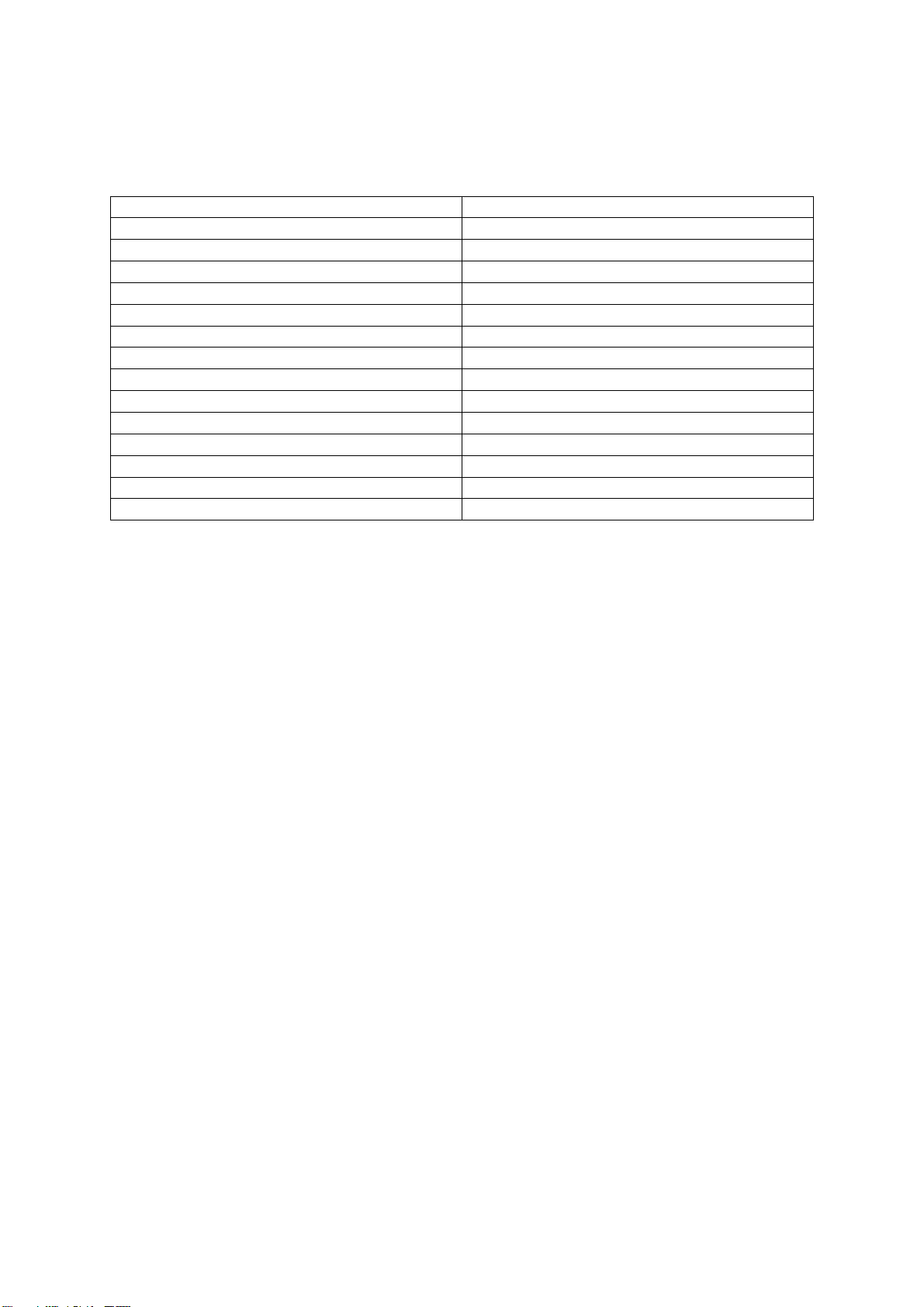

Pre-installation ...................................................................................................................................1

Safety Precautions ..........................................................................................................................2

Technical Specifications ..................................................................................................................3

Site Selection and Preparation ........................................................................................................4

Voltage Drop...............................................................................................................................4

Continuity Test for Earthing Conductor .......................................................................................5

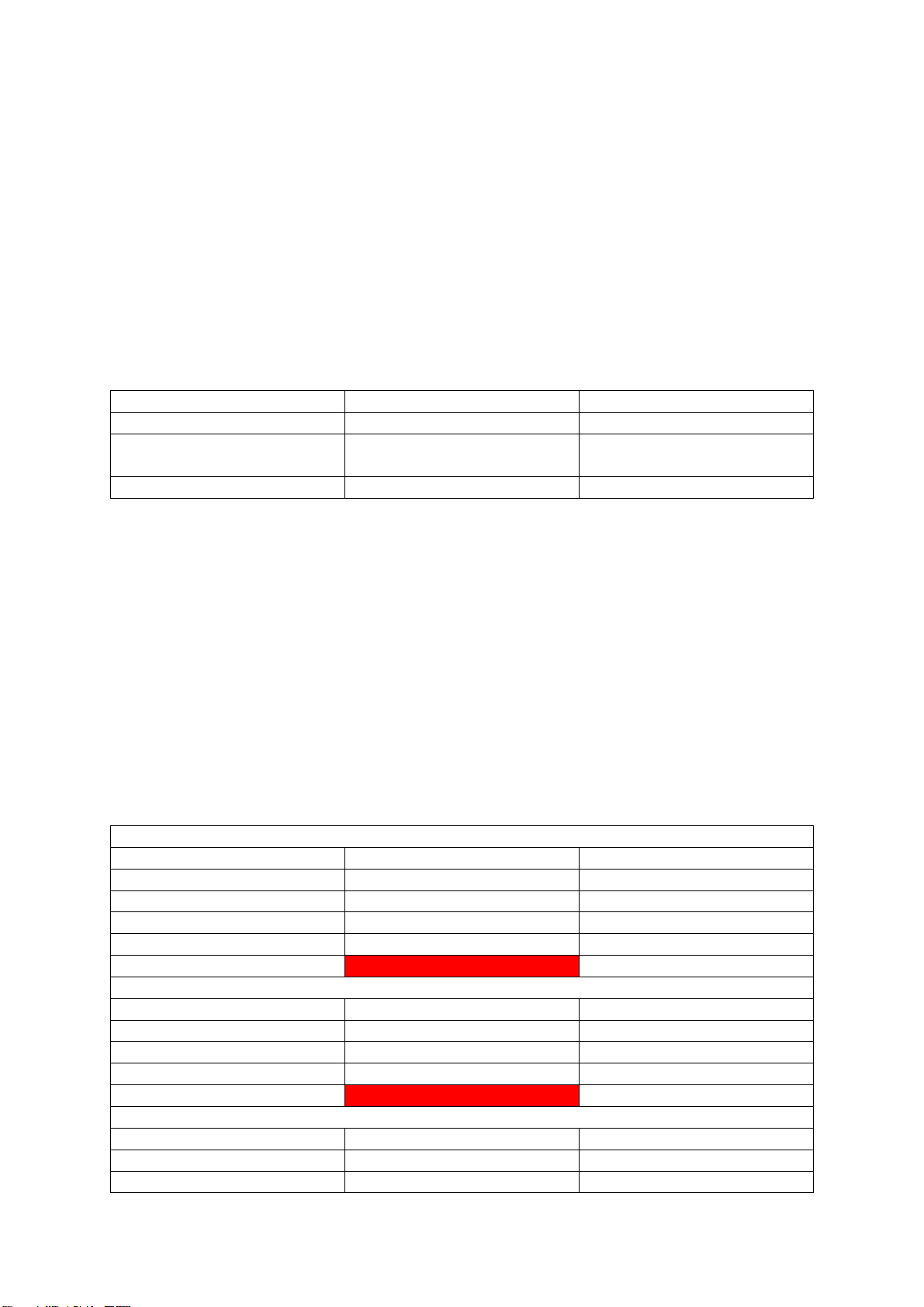

Electrical Installation Requirements ................................................................................................7

Earthing System ..........................................................................................................................7

Electrical Cables ..........................................................................................................................8

Stand ..........................................................................................................................................8

On the Wall...............................................................................................................................10

Examples of Wiring Systems......................................................................................................11

Connections for Multiple Chargers ............................................................................................12

Network....................................................................................................................................14

Energy Meter ............................................................................................................................14

Installation........................................................................................................................................15

Safety Precautions ........................................................................................................................16

Electrical Installation.....................................................................................................................17

Safety pillar installation.................................................................................................................21

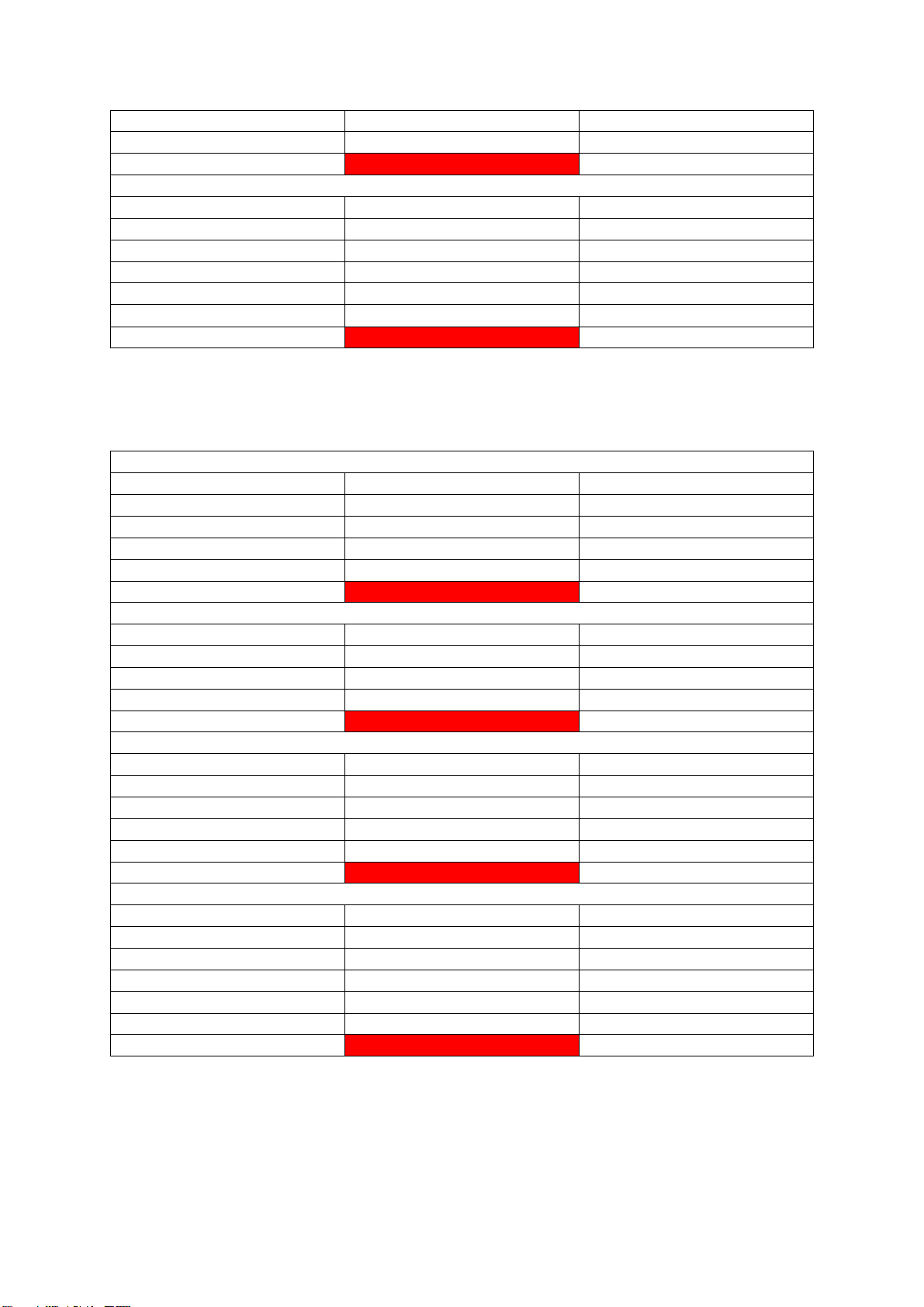

DLM Connection ...........................................................................................................................22

Energy Meter Connection..........................................................................................................22

DLM Connection .......................................................................................................................22

1 Phase Installation ...................................................................................................................24

Post Installation Maintenance.......................................................................................................25

General Inspection of the Station ..............................................................................................25

Check the Protection Elements..................................................................................................25

Configuration....................................................................................................................................26

Controller Update .........................................................................................................................27

RFID (Pulse Mode) Western Controller..........................................................................................29

LED Configuration Western Controller...........................................................................................30

Current Setting for Western Controller .........................................................................................31

Service..............................................................................................................................................33

Service..........................................................................................................................................34

Element Replacement ...............................................................................................................34

Troubleshooting........................................................................................................................34