Issued on: 19.10.2021

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Isotra a.s., Bílovecká 2411/1, 746 01 Opava, Czech Republic registered in the commercial register in Ostrava part B, insert 3169

tel.: +420 553 685 111, fax: +420 553 685 1110 Company ID number (IČO): 47679191, VAT number: CZ47679191

isotra@isotra.cz, www.isotra.cz Bank: ČSOB, A/C number: 381926893/0300

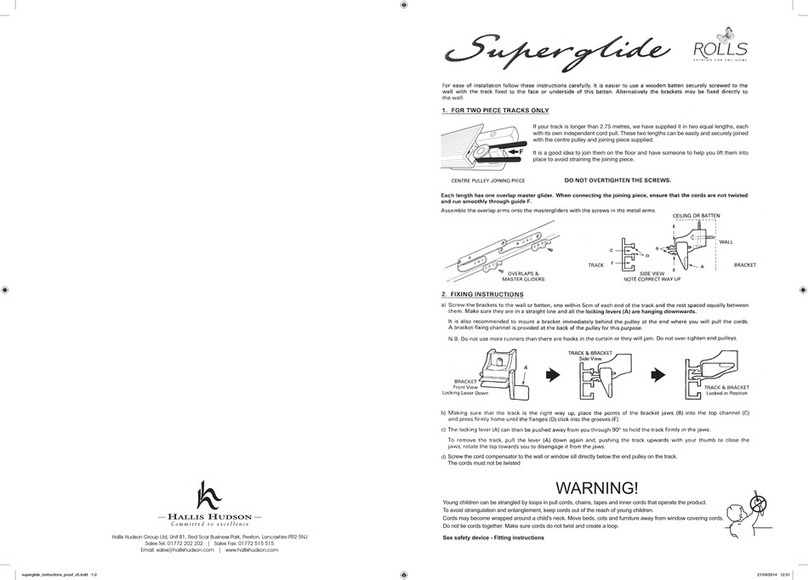

2.1 MANUAL CONTROL

The length of the blind lintel is determined by the width of the window opening as follows: add minimum laying

2 x 200 mm to the width of the window opening and select the closest higher lintel length that is fabricated.

The design of the lintel should already include the manner of the future roller shutter control - whether manual

(by a strap) or electrical.

Either control option can deal with the minimum position of 200 mm; however manual control, especially when

controlling the roller shutter by a strap, the recommended length of the lintel position is on the side of the

control: 220-250 mm, considering the fact that the axis of the manual control is always in the axis of the

sleeve, which is usually placed in a 140 mm distance from the end of the lintel. It means that:

●if the lintel is positioned in a 200 mm length, the axis of the strap is in a minimum distance of 60

mm from the jamb face,

●if positioned in a 220 mm then in an ideal distance of 80 mm from the jamb face,

●if positioned in a 250 mm the distance is 110 mm.

On the opposite side (i.e. on the side of the lintel where the manual control is not located), the minimum

positioning distance of 200 mm has to be kept; and more, depending on the width of the window opening and

the selected length of the lintel, i.e.

that the position of the lintel above the opening need not be symmetrical.

2.2 ELECTRICAL CONTROL

If control is electrical, lintel can be laid in 200 mm and more (depending on the clearance of the opening and

the selected length of the lintel); the lintel is usually located symmetrically above the structural opening.

3. PREPARATION OF BRICKWORK BEFORE ASSEMBLY

3.1 MANUAL CONTROL

3.1.1 OPENING FOR SLEEVE

The axis of the opening for strap from the lintel margin is 140 mm on either side. If lintel is positioned in 200

mm, the distance of the strap axis from the brick jamb of the window opening is 60 mm, and if lintel is

positioned in 250 mm, the distance is 110 mm. On the opposite side (i.e. on the side where location of the

manual control is not considered), the minimum positioning length of 200 mm or more has to be kept;

depending on the width of the window opening and the closest selected length of the lintel.