iWeld CUT 50 IGBT User manual

Other iWeld Welding System manuals

iWeld

iWeld GORILLA POCKETFORCE 200 IGBT User manual

iWeld

iWeld HD 220 LT DIGITAL PULSE User manual

iWeld

iWeld MIG 251 DIGITAL User manual

iWeld

iWeld TIG 220 AC/DC DIGITAL RC User manual

iWeld

iWeld GORILLA POCKETMIG 185 ALUFLUX User manual

iWeld

iWeld TIG 200 Digital Pulse User manual

iWeld

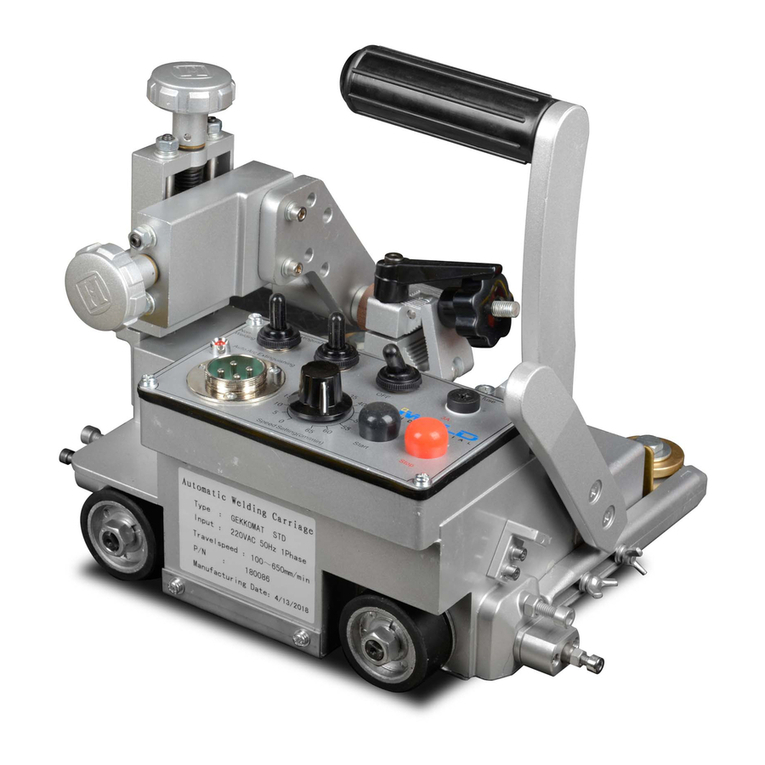

iWeld GEKKOMAT STD User manual

iWeld

iWeld GORILLA POCKETMIG 225 SYNERGIC User manual

iWeld

iWeld MIG 5200 SYNERGIC User manual

iWeld

iWeld GORILLA SUPERPULSE 200 User manual

iWeld

iWeld GORILLA POCKETPOWER 130 IGBT User manual

iWeld

iWeld POCKETMIG 205 DSC User manual

iWeld

iWeld GORILLA SUPERFORCE 230 IGBT User manual

iWeld

iWeld HD 200 MULTICELL User manual

iWeld

iWeld GORILLA POWERTIG 200 AC/DC GORILLA POWERTIG 200... User manual

iWeld

iWeld MIG 280 SYNERGIC PULSE User manual

iWeld

iWeld TIG200P AC Assembly instructions

iWeld

iWeld CUT 50 COM PILOT User manual

iWeld

iWeld GORILLA POCKETMIG 195 ALUFLUX User manual

iWeld

iWeld QUICKSILVER TIG 4200 AC/DC User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual