Grasp the pump body, wearplate and motor with one hand, holding

them together as an assembly. Then slide the mounting

lange/macerator housing off the pump body with the other hand

trying not to disturb the wearplate and damage the paper gaskets.

It may be necessary to gently tap on the flange with a plastic mal-

let to start it sliding off the pump body.

If the gaskets are damaged, they should be replaced with new

ones (provided) before attaching the new mounting flange/macera-

tor housing. To do this insert a blunt rod dowel into the discharge

hole in the pump body and push it against the impeller to prevent

the motor shaft from turning. Unscrew and remove the chopper

from the motor shaft. Lift the wearplate and gaskets from the pump

body and clean any paper residue which may stick to the wearplate

and body. Reassemble with new gaskets by reversing the proce-

dure.

Before assembling the new mounting flange/macerator housing to

the pump body, ensure the discharge port O-Ring is properly posi-

tioned in the O-Ring groove of the pump body. Secure the flange to

the pump body with the two shorter screws and the pump assem-

bly to the motor with the two longer screws.

Before removing the manual pump, flush the toilet for sufficient

time to ensure all waste is thoroughly flushed from the discharge

hose.

Remove the 3/4" inlet hose and toilet bowl link hose from the manual

pump. Detach the discharge elbow, flange and joker valve assembly

from the pump cylinder. It should not be necessary to remove the dis-

charge hose from the elbow.

Remove the screws which secure the pump assembly to the

toilet base and retain them to reattach the electric flush pump.

Remove the manual pump assembly and the base flapper

valve/gasket assembly with attached brass weight. The pump

and flapper valve may be disinfected and stowed away for emer-

gency use should the vessel lose electrical power.

Before assembling the electric flush pump to the toilet base,

attach the discharge elbow, flange and joker valve to the flush

pump discharge. Position the new pump base gasket (provided)

on the toilet base. Align the flush pump mounting flange with the

toilet base and secure it with the pump mounting screws.

Attach the 3/4" inlet hose to the inlet port (beneath the upper

pump pointing down). Do not connect the pump inlet to a pres-

surized water system. Attach the bowl link hose to the flush

pump discharge port (rear of upper pump pointing back). If the

bowl link hose is not long enough or is kinked, replace it with the

length of hose provided with the flush pump kit.

If the toilet is positioned below the waterline or may be below the

waterline at any angle of heel or trim, the plumbing must include

vented loops positioned above the waterline. To do this, remove

the length of hose which connects the flush pump with the bowl.

In its place install a length of hose long enough to connect the

flush pump to a vented loop fitting positioned a minimum of 8

inches above the waterline. Connect the other side of the vented

loop fitting to the bowl inlet elbow.

In below waterline installations with the discharge hose connect-

ed to a thru-hull fitting, the hose must rise up and be connected

to a vented loop positioned a minimum of 8 inches above the

waterline and then continue on to the discharge seacock. The

total rise of the discharge hose, however, must not exceed 6 feet

of head. If a vented loop fitting in the discharge hose positioned

at least 8" above the waterline results in a total discharge head

that exceeds 6 feet, the electric flush pump should not be

installed.

WIRING

The flush pump should be wired to the power source with an

electrical circuit independent of all other accessories. The total

length of wire should be kept to a minimum and the wire should

be sized in accordance with the following electrical specifications

chart. The wires, if not run through a conduit, should be support-

ed every 18 inches with non-metallic clamps.

NOTICE: Correct wire size and secure wire connections are

very important. Undersized wire and unsecured or corroded

wire connections will cause a reduction in pump performance

and possible pump failure.

The entire circuit should be protected by an appropriate

size circuit breaker or switch panel located as close to the

power source as possible.

Connect the red motor lead to positive and the black

motor lead to negative. When making connections to the

motor leads use only mechanical locking (crimp type) con-

nectors or equivalent and seal the connection with silicone or

heat-shrink tube to protect it from corrosion.

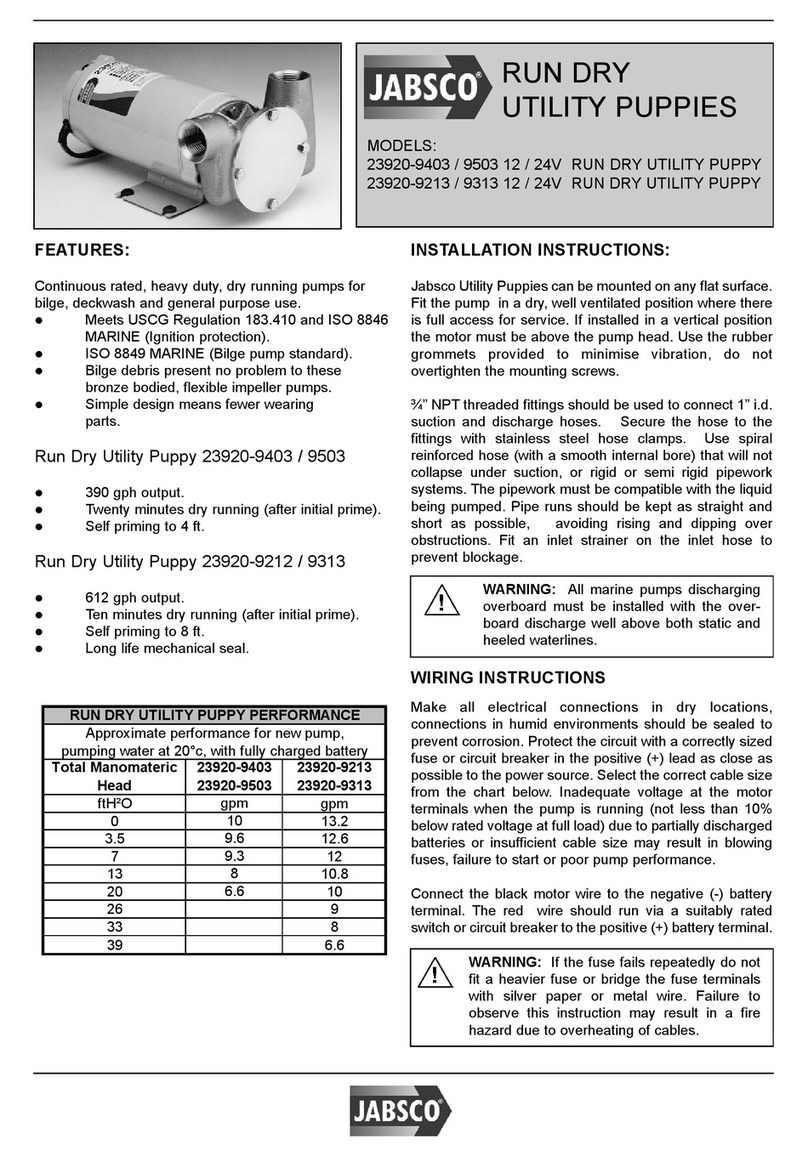

RATED NOMINAL FUSE WIRE SIZE PER LENGTH OF RUN*

VOLTAGE AMPS SIZE 0'-10' 10'-15' 15'-25' 25'-40' 40'-60'

12 24 25 12 10 8 6 4

24 13 15 16 14 12 10 10

*Length of run is the combined distance from the positive

power source to the flush pump and back to ground.

Wire sizes recommended will allow no more than a 5%

drop in voltage.

VENTED LOOP ILLUSTRATION

4. Remove the O-Ring around the discharge port.

5. Grip the flat of the shaft where it has been exposed by the

remove top pump assembly to prevent it from rotating.

Unscrew and remove the chopper and its lock washer.

6. Remove the wearplate and two gaskets from the

pump assembly.

7. Remove the pump body and impeller from the motor

then withdraw the impeller from the body.

8. Through the impeller bore side of the pump housing, push

evenly against the shaft seal to press it out of the bore.

WASTE PUMP REASSEMBLY:

1 .Press the lip seal into the seal bore of the pump body

with the open side of the seal facing the impeller bore.

2. Lubricate the impeller bore of the body and the motor

shaft with petroleum jelly then slide the pump body

onto the shaft.

3. Slide the impeller onto the shaft and with a counter-clock-

wise motion push the impeller into the impeller bore.

4. Position a new paper gasket, wearplate and second

paper gasket on the shaft against the pump body.

5. Grip the flat of the shaft on the top end of the motor to

prevent it from turning. Install the chopper lock washer

and the chopper on the bottom shaft.

6. Position the O-Ring in the O-Ring groove around the

discharge port.

7. Slide the macerator housing onto the pump body and

secure it with the two shorter screws.

8. Position the discharge flange on the same side of the motor

where the wire leads enter the case and secure the pump

assembly to the motor with the two longer screws.

FLUSH PUMP REASSEMBLY:

1. Press the lip seal into the bore of the pump body with

the open side of the seal facing the impeller bore.

2. Lubricate the impeller bore of the body and the motor

shaft with petroleum jelly.

3. Slide the pump body onto the shaft and secure it to the

motor with two screws. Slide the impeller onto the shaft

and with a clockwise rotary motion press it into the

impeller bore of the body.

4. Push the inlet control valve assembly into the cylinder

above the inlet port.

5. Position the switch spring on the spring locator post.

Insert the dowel pin in the switch and slide the pin in its

channel to position the switch. Connect the red power

leads to the switch.

6. Press the brass wearplate into the impeller bore area

ensuring the locator notch aligns with the locator tab in

the body.

7. Position the cork gasket over the top of the flush pump

housing. Position the flush pump cover on the housing

and secure it with the seven long screws. Hint: When

installing screws, press firmly downward on the screw

and rotate it counterclockwise until you feel the thread

‘click’ into its groove, then screw it in until tight.

8. Position the control knob in its socket and secure it with

one short screw. Install the Electric Flush Pump

Assembly on the toilet base by following instructions for

installation.

9. Attach the flush pump to waste pump bleed tube to the

lower and upper bleed ports.

OPERATION

NOTICE: Do not run pump dry for more than ten seconds.

To do so may result in damage to the pump impeller.

To flush the toilet simply turn the large flush control knob

clockwise to the flush position. In the flush position the

flush Pump provides rinse water to the bowl while the

waste pump simultaneously macerates and discharges

the waste. Hold it in the flush position long enough to

evacuate all waste.

To evacuate liquid from the bowl so it will not slosh while

underway, turn the flush control knob counterclockwise to

the drain position. In the drain position the flush pump will

lower the liquid level to the bottom of the china bowl while

incoming rinse water is reduced to a minimum.

If the toilet bowl is empty, a small amount of water may be

added to the bowl prior to use by turning the flush control

knob to the flush position.

The waste pump is designed to handle waste and toilet

tissue (either household type tissue or Marine/RV water

soluble tissue is acceptable) but it will not handle sanitary

napkins, tampons or hard solid objects.

SERVICE INSTRUCTIONS

1. Disconnect the electrical power to the flush pump.

2. Detach the discharge elbow, flange and joker valve

3. Remove the inlet hose and toilet bowl link hose from

the flush pump.

4. Remove the screws that attach the flush pump to the

toilet base and lift the pump assembly from the base.

FLUSH PUMP DISASSEMBLY:

1. Remove the control knob screw and the control knob.

2. Remove the seven screws which attach the flush pump

cover assembly to the pump body and lift off the cover

assembly and the cork gasket.

3. Lift the brass wearplate and the flushing pump impeller

out of the impeller bore.

4. Carefully lift the switch from the pump housing taking

care not to lose the positioning dowel pin and gently

disconnect the red wire leads.

5. Using a blunt punch or small piece of dowel inserted in

the inlet port, push upward on the control valve assem-

bly to dislodge it from the flush pump housing.

6. Remove the two screws which secure the flush pump

housing to the motor and lift the pump housing off

the motor.

7. Through the impeller bore side of the pump housing,

push evenly against the shaft seal to press it out of the

seal bore.

WASTE SYSTEM DISASSEMBLY:

1. Remove the flush pump to waste pump bleed tube.

2. Remove the four screws that secure the macerator

housing and pump assembly together and to the motor.

Note that they are two different lengths with

the longer screws securing the pump assembly to

the motor.

3. Grasp the waste pump body and motor then pull the

macerator housing off the pump body.