English

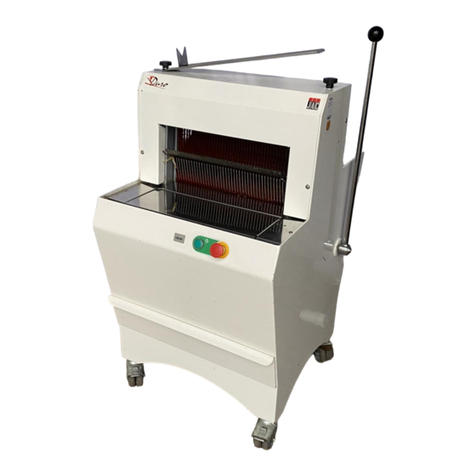

Chute continuous cut slicer

1BEFORE COMMISSIONING ......................................................................................................... 6

2WARRANTY .................................................................................................................................. 6

3WARNING ...................................................................................................................................... 7

4TECHNICAL SPECIFICATIONS ................................................................................................... 8

4.1Technical specifications .................................................................................................................... 8

4.2Details of materials in direct contact with dough. ........................................................................... 8

4.3Shaped grid: Teflon + Polyoxymethyl Details of materials in direct contact with the bread. ..... 8

5INSTALLATION AND COMMISSIONING ..................................................................................... 8

5.1Unpacking the machine: .................................................................................................................... 8

5.2Positioning: ......................................................................................................................................... 9

5.3Electrical connection: ........................................................................................................................ 9

5.4Commissioning: .................................................................................................................................. 9

5.5Commissioning: ................................................................................................................................ 10

5.6Danger: .............................................................................................................................................. 10

6CONTROLS AND SAFETY FEATURES ..................................................................................... 10

6.1Controls: ............................................................................................................................................ 10

6.2Work area: ......................................................................................................................................... 10

6.3Safety features: ................................................................................................................................. 10

7OPERATION ................................................................................................................................ 11

8MAINTENANCE ........................................................................................................................... 12

8.1Daily, by a trained operator. ............................................................................................................ 12

8.2Every 25,000 loaves and/or at least once a year, by an approved agent. ................................... 12

8.3Blade replacement. ........................................................................................................................... 12

9CONSUMABLES ......................................................................................................................... 13

9.1List of CONSUMABLES .................................................................................................................... 13

10MALFUNCTIONS ..................................................................................................................... 14

11LIST OF COMPONENTS IN ILLUSTRATIONS ....................................................................... 15