English

English

1 BEFORE COMMISSIONING

Thank you for choosing a JAC system. It is essential that you read these instructions

before installing and commissioning this machine. This will protect you and avoid damaging

your machine.

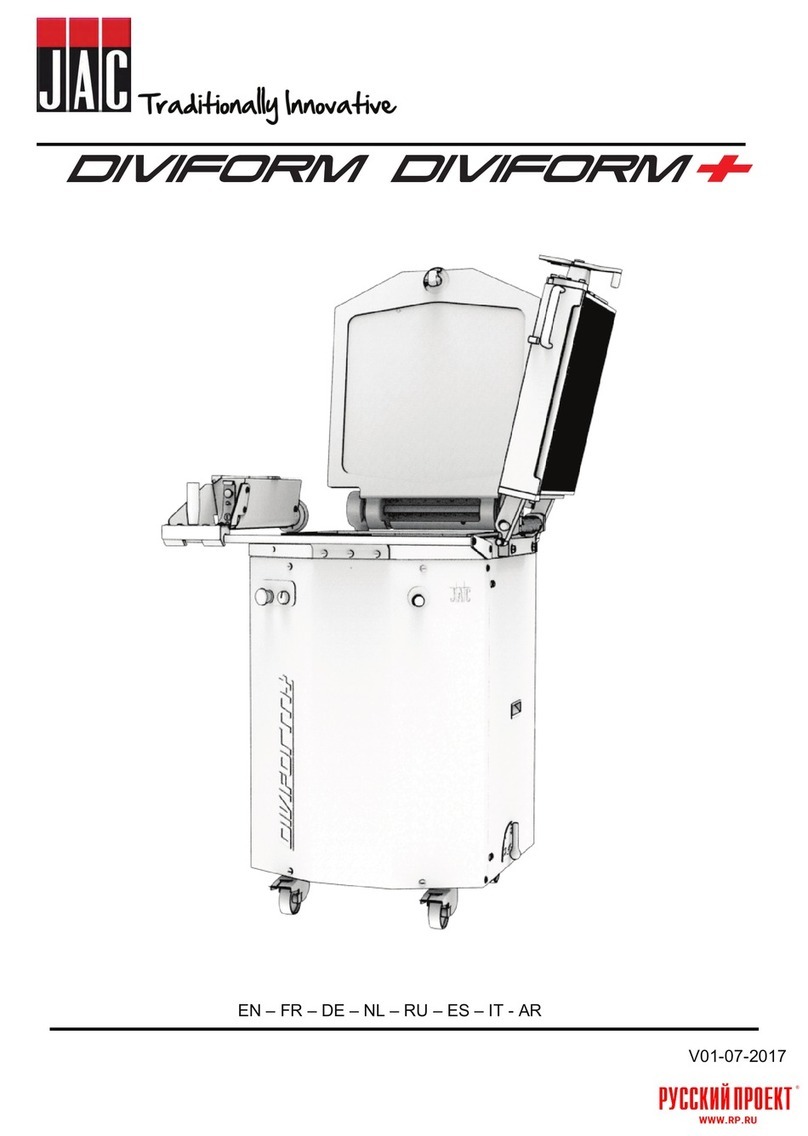

These instructions refer to various illustrations in order to make them easier to understand.

These illustrations are at the end of the instructions. Please refer to them whenever you see

the following symbols: (fig.X, n°Y).

To ensure that your machine gives you full satisfaction over the coming years, we

invite you to familiarise yourself with the following advice:

- Enlist the help of your approved agent for installation, commissioning and service support.

- In order to be covered by the 5-year warranty (see terms and conditions set out below),

please have your dealer fill in the service booklet when your machine is being installed. The

service booklet is at the back of your machine.

2 WARRANTY

All JAC products are covered by a 5-year warranty.

This warranty is valid for all parts on your machine, including electronic components but

excluding consumables. The warranty takes effect on the date the equipment is installed.

Subject to the following restrictive conditions:

- Equipment acquired from an approved dealer;

- Installation carried out by an approved agent;

- Equipment used in accordance with the instructions for use and for the intended purpose

for which it was manufactured;

- Equipment serviced on a daily basis in compliance with the instructions for use;

- Regular servicing by the approved agent in compliance with service specifications, with

at least one service a year (servicing chargeable to the user).

- Exclusive use of genuine JAC parts.

If there is no record of servicing by an approved agent and/or if the service booklet

has not been filled in correctly, warranty cover will be limited to one year.

This warranty does not cover:

- Replacement of consumables (§9);

- Parts not accepted as defective by our company;

- Problems due to improper use of the equipment;

- Problems due to installation not carried out by an approved agent;

- Parts or problems due to transit damage or improper handling.

Repairing and/or replacing defective parts during the warranty period does not

bring about an extension of said warranty.