Place the �n on the gears

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

Place the �n on the gears

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

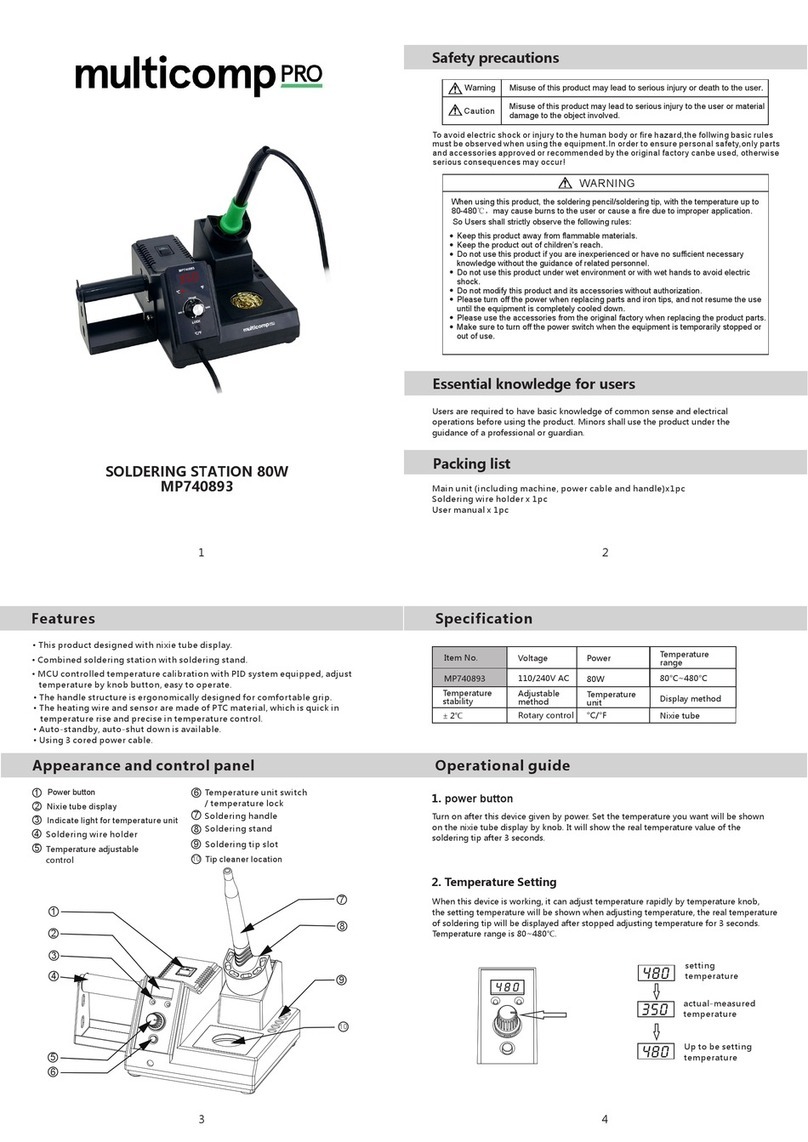

Changing Guide Sets

Assemble the counter wheel (1).

Insert the intermediate nozzle (2) until its collar

rests against the housing and tighten the screw.

Assemble the inlet nozzle (3).

Assemble the guide wheel (4) and tighten the

screw.

Assemble the blade first, then mount the

blade clamp (5) onto the same axis and tighten

the screw. Caution: handle the blade carefully

to avoid injury.

Insert the guide set (6).

Assembly with Solder Wire Perforation: Assembly without Solder Wire Perforation:

Changing Wheels and Blade

For this operation, disconnect the device from the mains. Disconnect the tool from the control unit

and open its cover.

First disassemble the guide tube (6), the nozzles (2)+(3), then the wheels, blade and clamp (4)+(5).

Disassemble the counter wheel (1). Use the allen key and the spanner, provided with the station.

Assemble the counter wheel (1).

Insert the intermediate nozzle (2) until its collar

rests against the housing and tighten the screw.

Assemble the inlet nozzle (3).

Assemble the traction wheel (4) onto the axis

and tighten the screw.

Assemble the support wheel (5) and tighten

the screw.

Insert the guide set (6).

Traction

Wheel Support

Wheel

Interm.

Nozzle

Inlet

Nozzle

Counter

Wheel 1

23

4

5

Inlet

Nozzle

Interm.

Nozzle

Blade

Blade

Clamp

Guide

Wheel

Guide

Set

Guide

Set

Counter

Wheel 1

2

3

4

5

66

Guide

Set

6Guide

Set

6

Blade

Blade Clamp

Inlet

Nozzle

Guide

Wheel

Intermediate

Nozzle

Traction

Wheel

Support

Wheel

Intermediate

Nozzle

Inlet

Nozzle

Counter

Wheel

Counter

Wheel

1

4

1

2

3

4

5

5

4

2

3

5

40 mm

50 mm

60 mm

80 mm

100 mm

130 mm 130 mm

para manuales - color gris

200 mm

300 mm