8

Profiles by Temperature

The usual way to run a profile is using the Thermocouple (TC) connected to the Control Input of the

console. JBC offers 3 predefined profiles (JBCset) and 10 profiles ready for you to personalize.

Why Infrared? The most efficient technology for PCB preheating

This is the most advanced, efficient and cost-effective method to preheat PCBs in any soldering job

or rework job. The low thermal mass of the infrared element gives outstanding control of the heat

output and the process temperature. This technology provides fast response, high heating rates and

uniform heating that ensure the best results.

Operation

JBCset profiles

There are 3 profiles predefined by JBC: A, B and C. The difference between them is the number

of steps: 2, 3 or 4. The thicker your PCB is and the more layers it contains, the more steps are

needed to obtain a gradual warming.

These profiles are not modifiable but they can be used as a template to create your own profiles.

JBCset A

2 steps

JBCset B

3 steps

JBCset C

4 steps

For repetitive jobs we recommend running profiles without the Thermocouple (TC). Once any

profile has been run to the end, the system has all the process data which you can save.

Once it is saved, you can run this profile without connecting the Thermocouple (TC). The heating

process will the same as long as the same working conditions are respected.

User profiles

You can create your own profiles from the JBCset profiles. On the work screen of the profile,

press the Enter button and choose the option Edit profile.

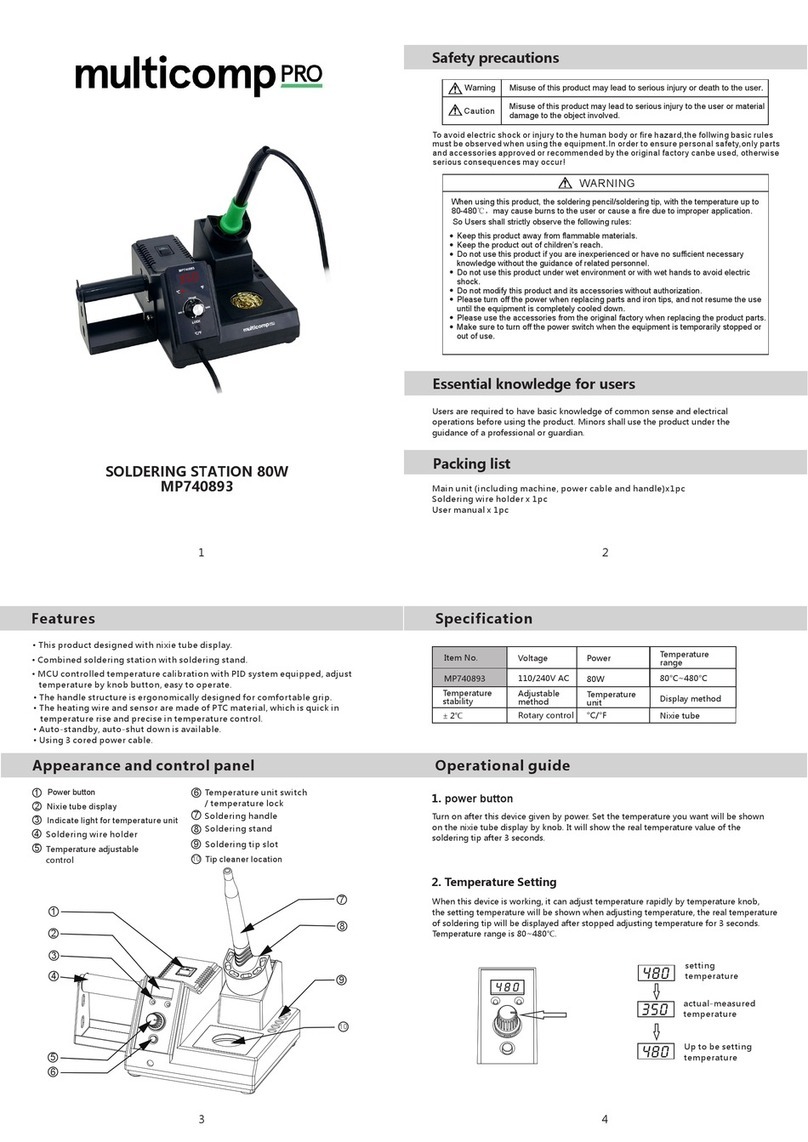

Power Mode

The unit works at the selected power or temperature during the defined time. These parameters can

be modified from the work screen by pressing the Enter button and the Edit parameters menu.

To see the current temperature you must plug the Thermocouple (TC) into the Control connector.

PCB reference

specifications:

FR4 1,6mm thick

and 2 layers.

FR4 2,2mm thick

and 6 layers.

FR4 1,6mm thick

and 6 layers.

Profiles set using the low position of the PHS-SA Support (28 mm in height between the PCB and the heating area).