Series TY-FRB, 5.6 K-factor

Upright, Pendent, and Recessed Pendent Sprinklers

Quick Response, Standard Coverage

Page 1 of 4 AUGUST 2018 TFP172

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

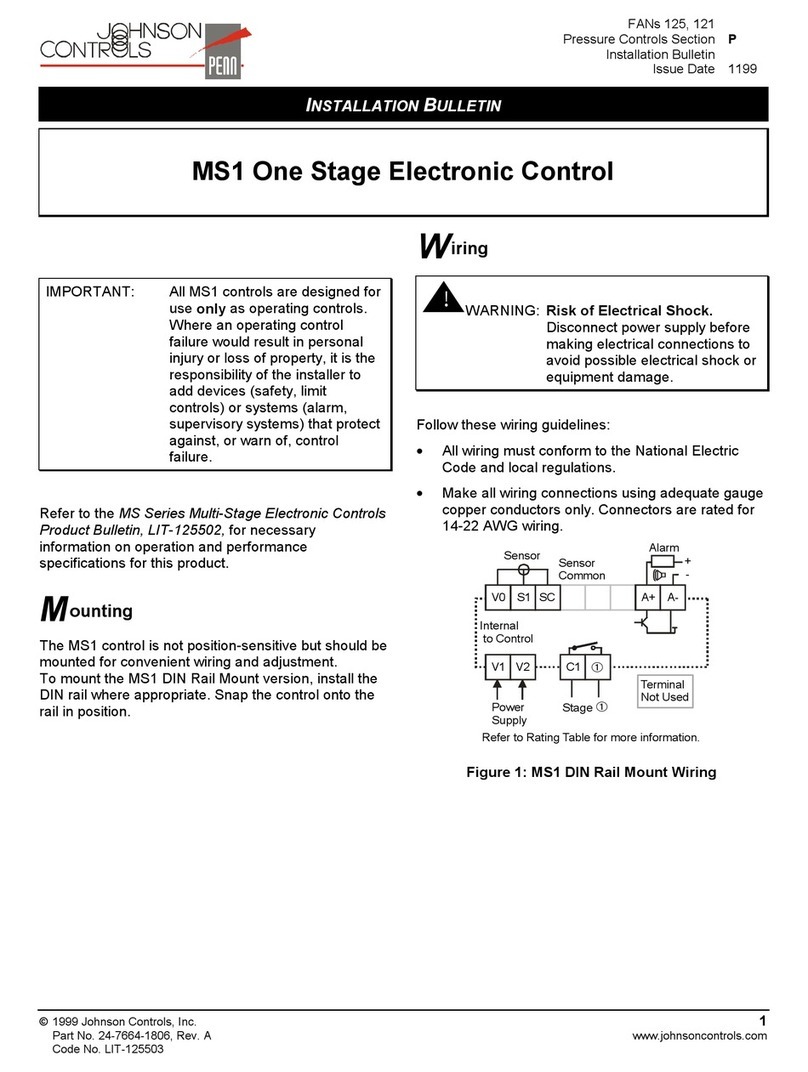

General

Description

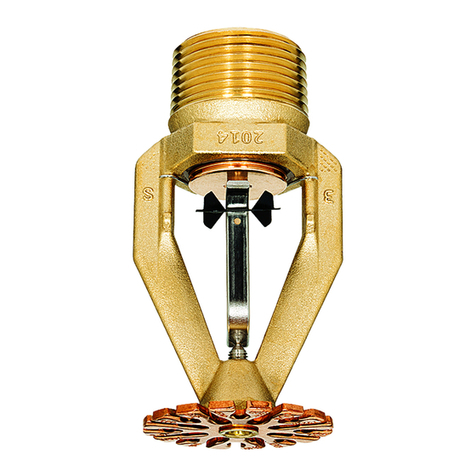

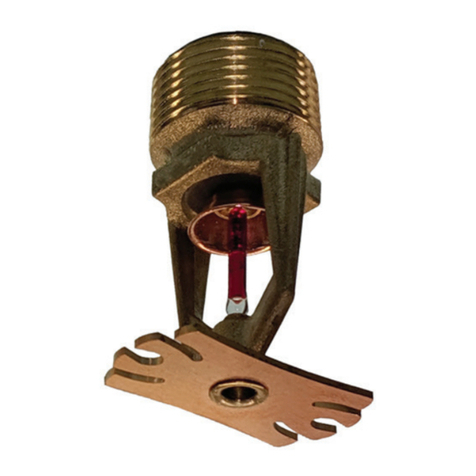

The TYCO Series TY-FRB, 5.6 K-factor,

Upright (TY313) and Pendent (TY323)

Sprinklers described in this data sheet

are quick response, standard coverage,

decorative 3 mm glass bulb-type spray

sprinklers designed for use in light or

ordinary hazard, commercial occupan-

cies such as banks, hotels, and shop-

ping malls.

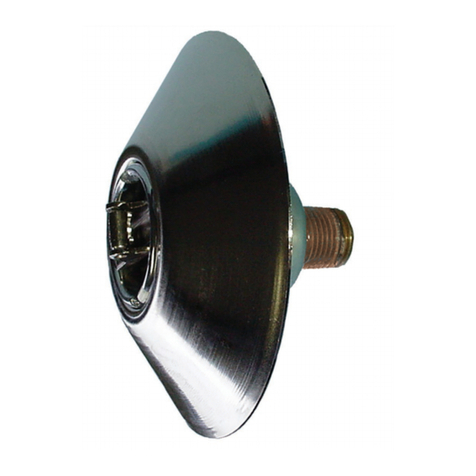

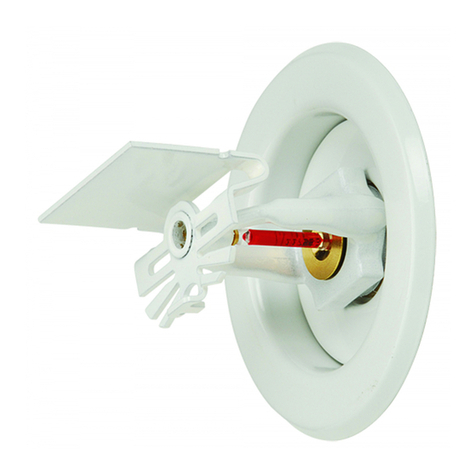

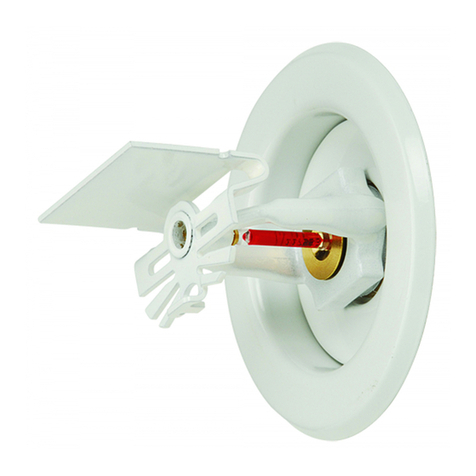

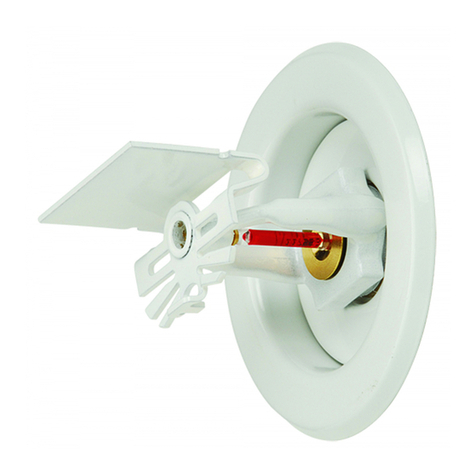

The recessed version of the Series

TY-FRB Pendent Sprinkler, where

applicable, is intended for use in areas

with a finished ceiling. This recessed

pendent sprinkler uses one of the

following:

•

A two-piece Style 15 Recessed

Escutcheon with recessed adjust-

ment up to 5/8 in. (15,9 mm) from

the ush pendent position.

•

A two-piece Style 20 Recessed

Escutcheon with recessed adjust-

ment up to 1/2 in. (12,7 mm) from

the ush pendent position.

The adjustment provided by the

Recessed Escutcheon reduces the

accuracy to which the fixed pipe drops

to the sprinklers must be cut.

Intermediate level versions of Series

TY-FRB Sprinklers are described in

Technical Data Sheet TFP357. Sprin-

kler guards and shields are described

in Technical Data Sheet TFP780.

NOTICE

The TYCO Series TY-FRB Sprinklers

described herein must be installed

and maintained in compliance with

this document, as well as with the

applicable standards of the National

Fire Protection Association, in addition

to the standards of any other authori-

ties having jurisdiction. Failure to do so

may impair the performance of these

devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Sprinkler

Identification

Number (SIN)

TY313 . . . . Upright 5.6K, 1/2 in. NPT

TY323 . . . .Pendent 5.6K, 1/2 in. NPT

Technical

Data

Approvals

Refer to Table A

Maximum Working Pressure

175 psi (12.1 bar)

250 psi (17.2 bar)*

* The maximum working pressure of 250 psi (17.2 bar)

only applies to the listing by Underwriters Laborato-

ries, Inc. (UL).

Discharge Coefficient

K=5.6 GPM/psi½(80,6 LPM/bar½)

Temperature Rating

Refer to Table A

Finishes

Sprinkler: Refer to Table B

Recessed Escutcheon: White Coated,

Black Coated, Chrome Plated, or Brass

Plated

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Button . . . . . . . . . . . . . . . . . . . . . . Brass/Copper

Sealing Assembly ...Stainless Steel w/TEFLON

Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass

Compression Screw . . . . . . . . . . . . . . . . .Bronze

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Operation

The glass bulb contains a fluid which

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

Design

Criteria

The TYCO Series TY-FRB, 5.6 K-factor,

Upright (TY313) and Pendent (TY323)

Sprinklers are intended for fire protec-

tion systems designed in accordance

with the standard installation rules

recognized by the applicable Listing or

Approval agency (such as, UL Listing

is based on the requirements of NFPA

13, and FM Approval is based on the

requirements of FM’s Loss Prevention

Data Sheets). Only the Style 15 or Style

20 Recessed Escutcheon is to be used

for recessed pendent installations.