J+J

subject to technical changes

Manual J4C S20-S300

-PAGE 4-

J+J®Deutschland GmbH Brunnenweg 7

31061 Alfeld Tel.: +49 5181 85590-0

www.juj-deutschland.de

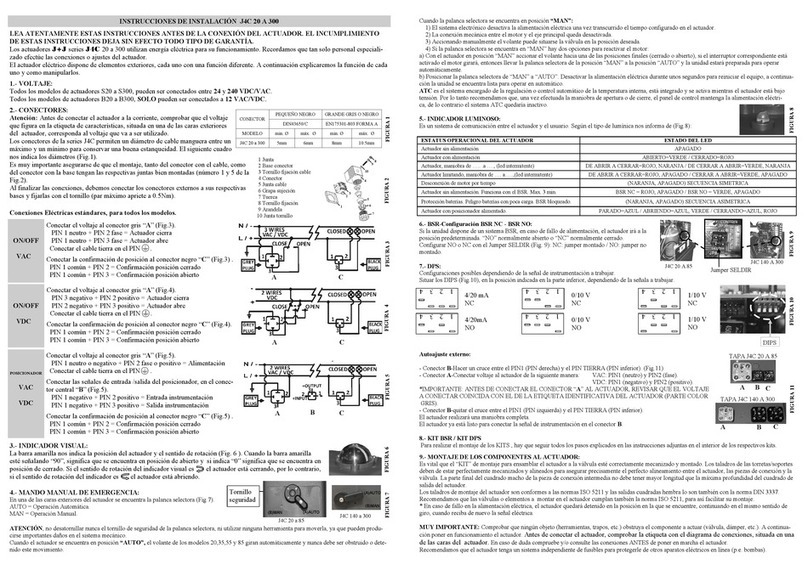

Adjustment of the cam system

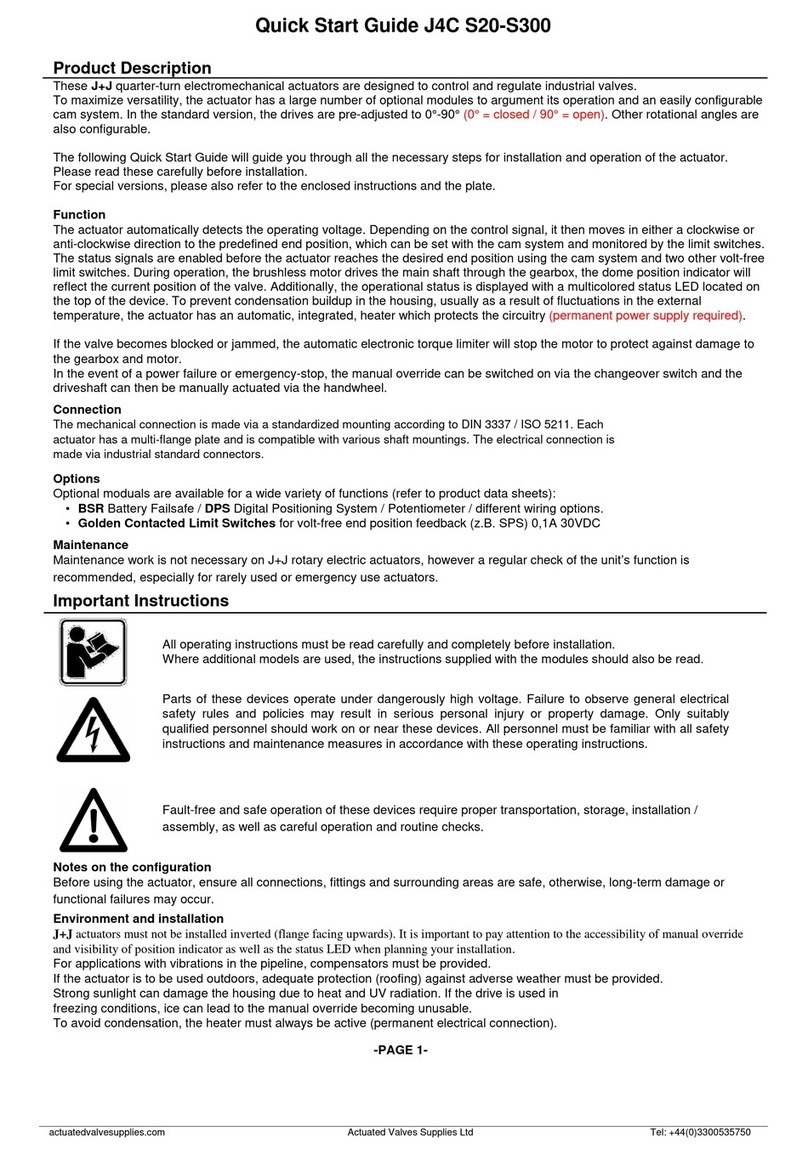

With the cam system, the working angle as well as the end position feedback of the actuator can be adjusted.

The drive is pre-adjusted ex works (see type label). Depending on application, valve, lack of alignment or adapters, it may be

necessary that the drive has to be adjusted in its travel.

All work on the opened actuator must be under protective extra-low voltage or without any voltage applied

and carried out by appropriately qualied personnel. Not complying with the general Electro safety rules can

result in serious injury or property damage.

Volt free end position feedback

Cam 1 (green) Position „open“

Cam 2 (red) Position „close“

Motor shutdown

Cam 3 (green) Position „open“

Cam 4 (red) Position „close“

1. Open the housing

Needed tools: Allen Key 3mm (Models 35-300), Torx key T20

To adjust the cam system, the housing must rst be opened. Particular care should be taken to ensure that all sealings and

screws are carefully stored. The following steps have to be carried out:

• Unscrew all plugs (watch the plugs sealing)

• Loosen screw in handwheel and pull handwheel upwards

• Loosen and remove the housing screws

• Remove the cover (observe the circumferential housing seal, as well as the shaft seal and snap ring of the handwheel)

• Lay the cover aside (cables can remain connected to the board) and pay attention to the original cable routing

• Put handwheel back on (to turn it while adjusting the cams)

2. Adjusting the cams

For adjustment, rst the adjusting

tool is needed, which is attached

to the motor. To adjust a cam, the

tool needs to be plugged in it, as

shown in the picture „plugged in

tool“. By turning the tool, the cam

can now be adjusted.

Plugged in tool

3. Close the housing

After completing the adjustment, the actuator can be closed again by reversing the steps described under point 1 in reverse order.

Particular care must be taken to ensure that all screws, seals, individual parts and the internal cable routing are returned to their

original position.

Proceeding: The Actuator is rst switched from AUTO to MAN.

The position to be set is then approached by handwheel.

Now the adjusting tool is plugged in the respective cam and is twisted until the click

sound of the microswitch is heard. The cam must always be turned to the switch from

the direction which the main shaft will move in electrical operation to this position.

The end position feedback is set to switch shortly before reaching the end position.

The correct setting of the cam positions must always be checked with an electrical

test drive (use safety extra-low voltage). The end positions can be measured with a

continuity tester on the plug (see wiring diagram).

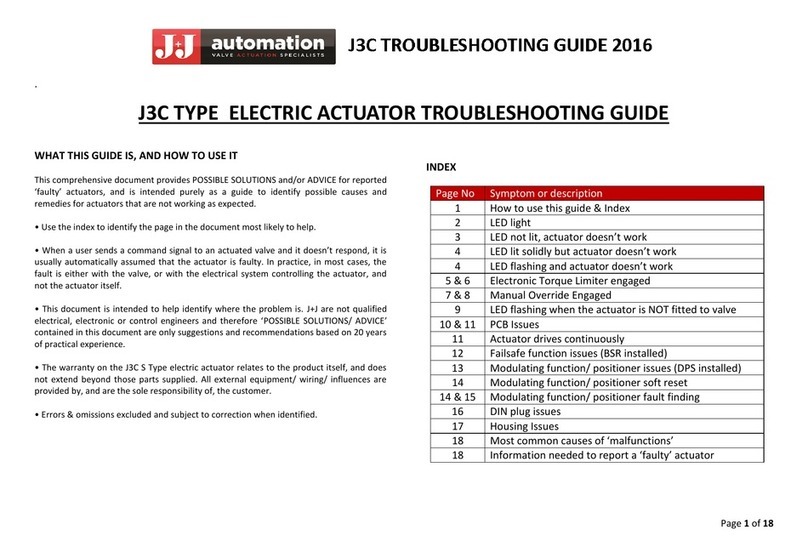

Troubleshooting

The actuator moves and then stops. The operating LED ashes red or green (see status LED).

»High torque on the valve due to not removed end stops or solids in the valve. Valve must be checked!

»Model size of the actuator is too small.

The actuator is in position „open“ but the valve is closed or half opened.

»Actuator is mounted on the valve with a wrong angle. Dismount, turn the actuator in manual mode to correct angle, mount it.

The limit switches for end position feedback do not work.

»Check the wiring. Check the adjustment of the cams so that they trigger shortly before reaching the end position.

»In load-free interrogation of the limit switch, soot is formed inside. Actuator with gold contact switches are to be used.

The actuator moves, but the valve does not.

»The connection between actuator and valve is damaged or incorrectly dimensioned.

For other malfunctions, please contact our technical service department.

Geändert: 12.12.2018

Name: MU

Angle

Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)