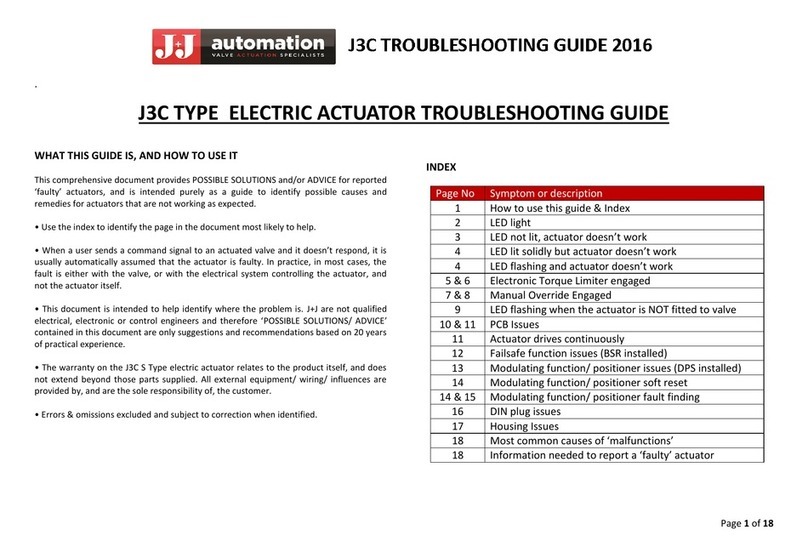

J3 Status light functions:

The LED flashes on/ off

When the valve actuator senses

an impending valve jam, the

electronic torque limiter is

activated and on activation,

repeatedly flashes the LED on

and off.

Constantly lit LED

If the electric actuator is operat-

ing correctly with no faults, the

LED shows a constantly lit

light.

The LED flashes with 2 blinks

If the actuator has been left in

‘manual’ mode, the actuator’s

motor runs but doesn’t drive

the output shaft. After a pre-set

time, the actuator knows that

as the torque limiter has not

activated and that the motor is

running, it must be in manual.

Aug 2010

Doc: J3-H85/07 KW

the manual override to be se-

lected to assist in clearing the

jam.

The effect of condensation in

the J3 electric actuator is

eliminated by an internal ther-

mostatic anti-condensation

heater that does not require a

separate independent power

supply.

Standard function for the

J3-H85 electric valve actuator

is power open, power close,

stays put on power

failure.

New to the J3 electrical actu-

ators are plug and play accesso-

ries –the function can be

changed to either failsafe or

modulating by fitting the new

plug and play conversion kits.

The modulating kit has the new

digital positioner that offers

auto-calibrating and self reset-

ting functionality. These conver-

sion kits are available as option-

al extras.

The J3 is a very smart red box!

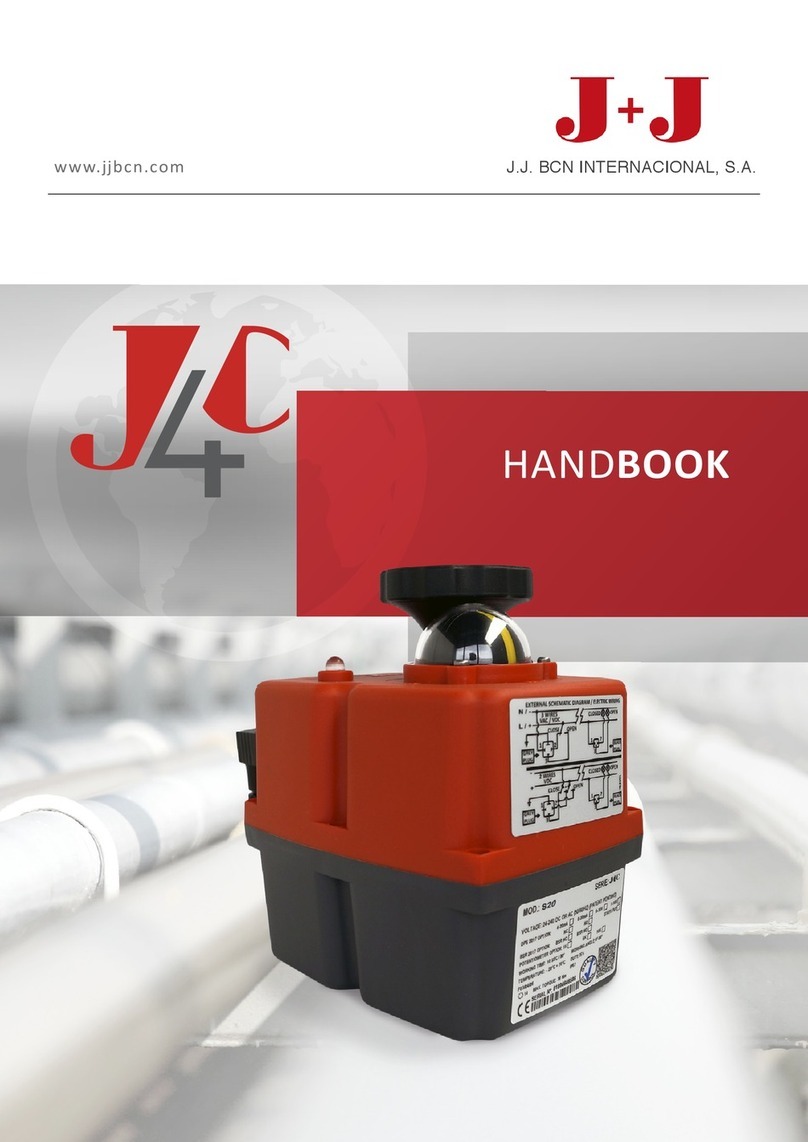

Feature rich J+J multi-voltage electric actuator

with LED status light and plug & play accessories.

New in 2008, the J3 range of

electric actuators takes its high-

ly successful predecessor, the J2

range, to the next level.

With an all new, rugged weath-

erproof and anti-corrosive

Polyamide housing, the J3

valve actuator offers more user

-friendly features than the J2,

and introduces a highly visible

LED status light.

This visual indicator shows

whether the actuator is operat-

ing correctly, or has tripped out

either by its electronic torque

limiter, or has been left in

‘manual’ mode.

Site operators are no longer

left with the ‘valve or actuator?’

question when an actuator

doesn’t respond to a signal.

The J3 rotary electric actua-

tor is quick and easy to install,

with IS0:5211 multi-

flange mounting and a double

square drive, allowing fast

mounting to ISO:5211 valves.

There is no need to remove the

cover to connect the J3 electri-

cally, saving installation time.

Using the external DIN plugs and

external wiring diagrams supplied

with the actuator, installations

can be pre-wired.

Protection against valve jams is

provided by an electronic torque

limiter, which auto-relaxes the

gearbox when activated, allowing

Quick guide to the

J3 electric actuator:

Standard Features

Multi-voltage electric actuator

with auto-voltage sensing.

110 ~ 24V0 AC or DC .

LED Status light to indicate

operational status of actuator

Electronic over-torque protec-

tion against valve jams

Thermostatic anti-condensation

heater

Manual override for emergency

hand operation

2 Volt free end of travel confir-

mation switches

IP65 weatherproof anti-

corrosive and UV protected

Polyamide housing

Local visual position indicator

ISO5211 multi-flange mounting

with double square drive

All external electrical connec-

tions via supplied DIN plugs

CE marked

IS0 9000 manufacturer

Failsafe and digital

positioner plug & play kits

available.

Model J3 - H85

Electric Actuator