CONTENTS

Specications ............................................................................................................ 1

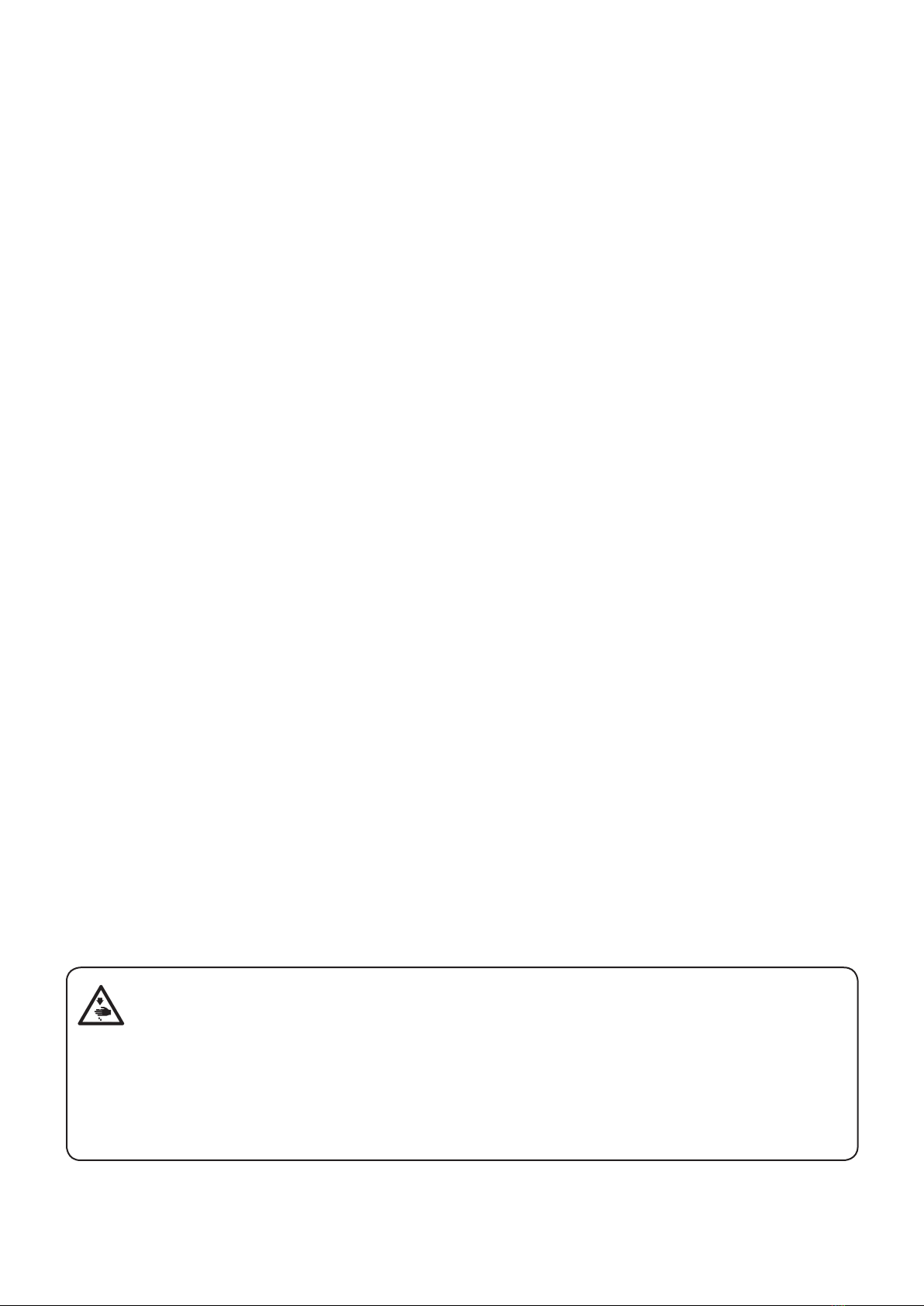

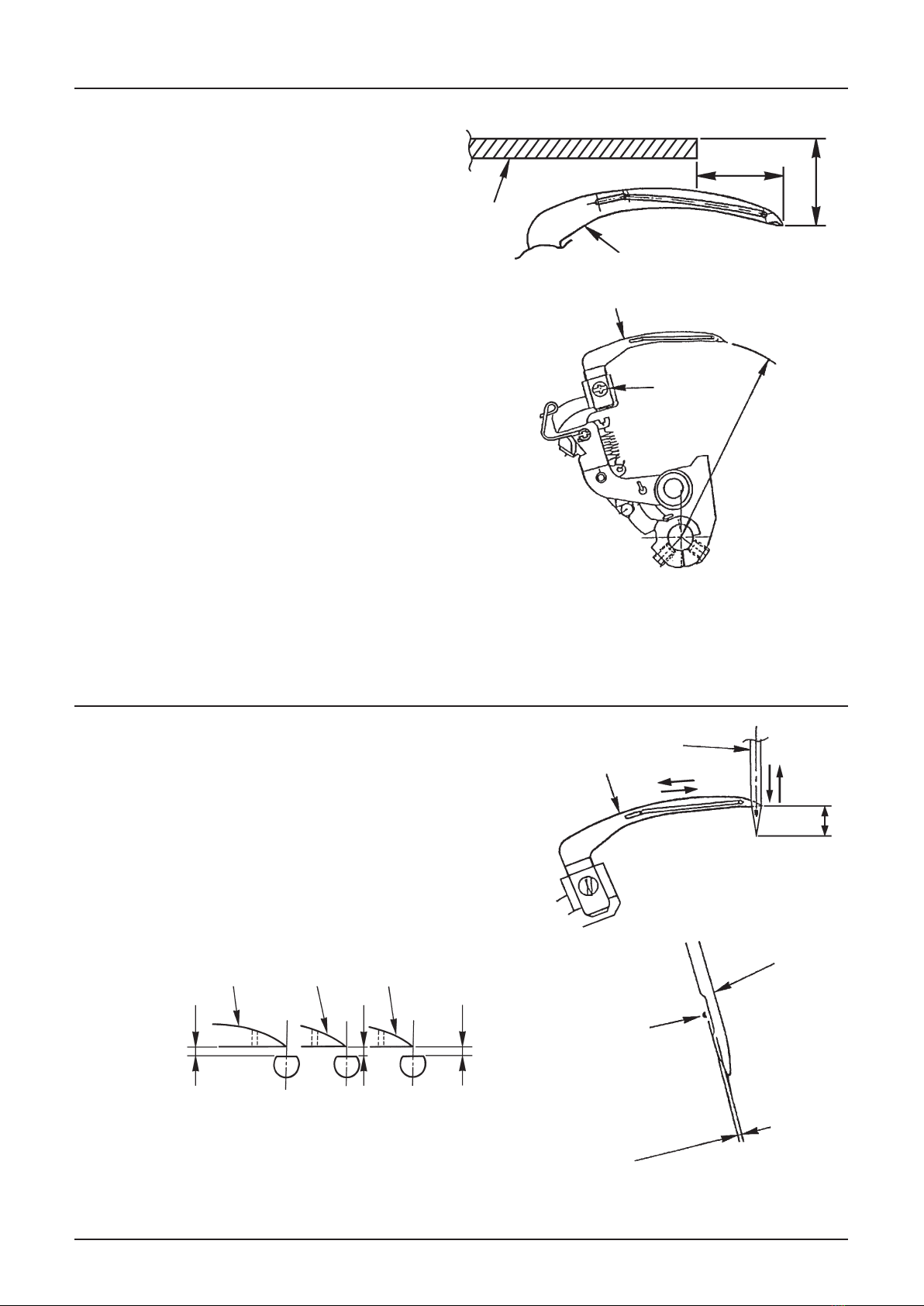

1.Installationofthethroatplate .............................................................................. 1

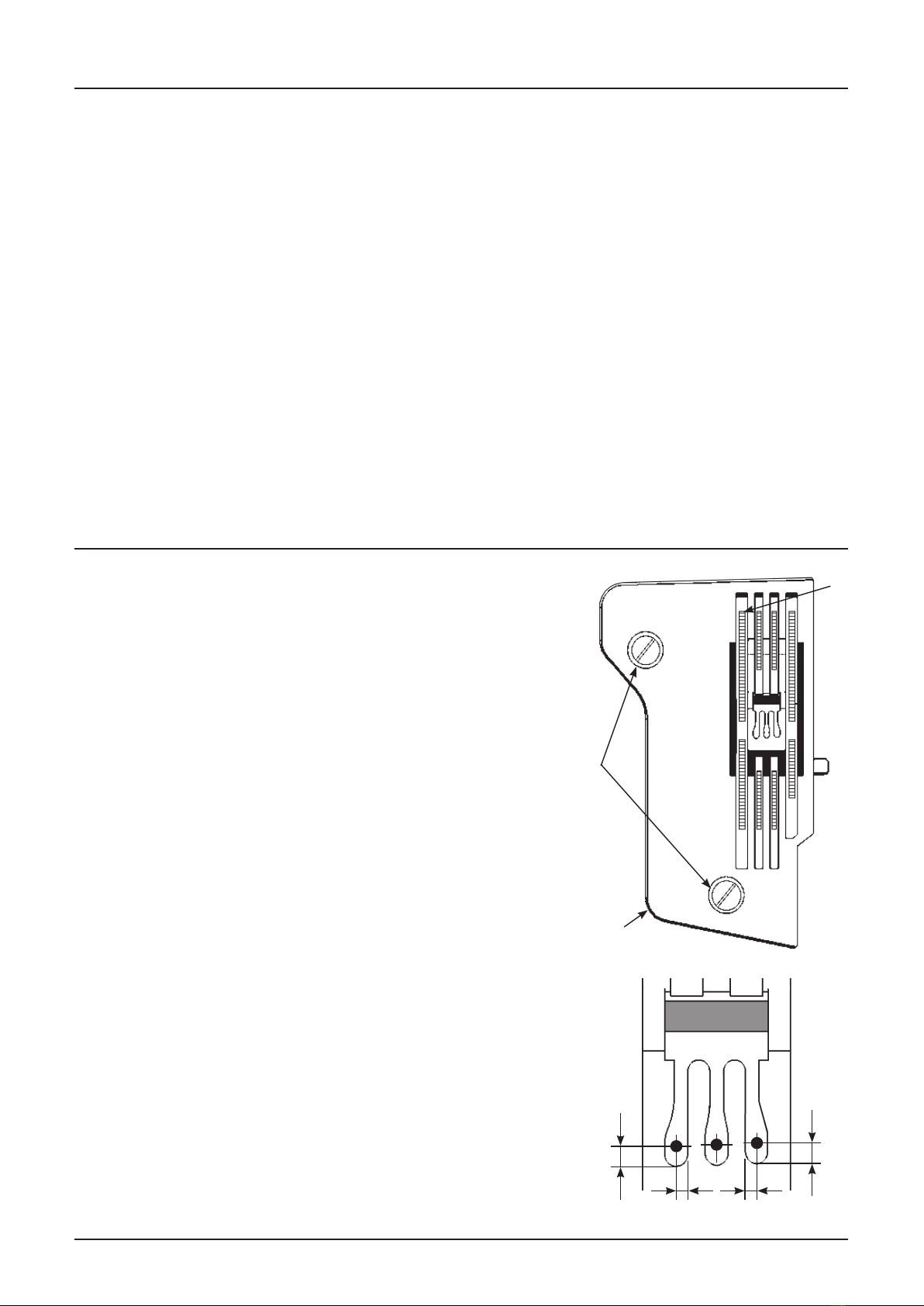

2.Heightoftheneedlebar........................................................................................ 2

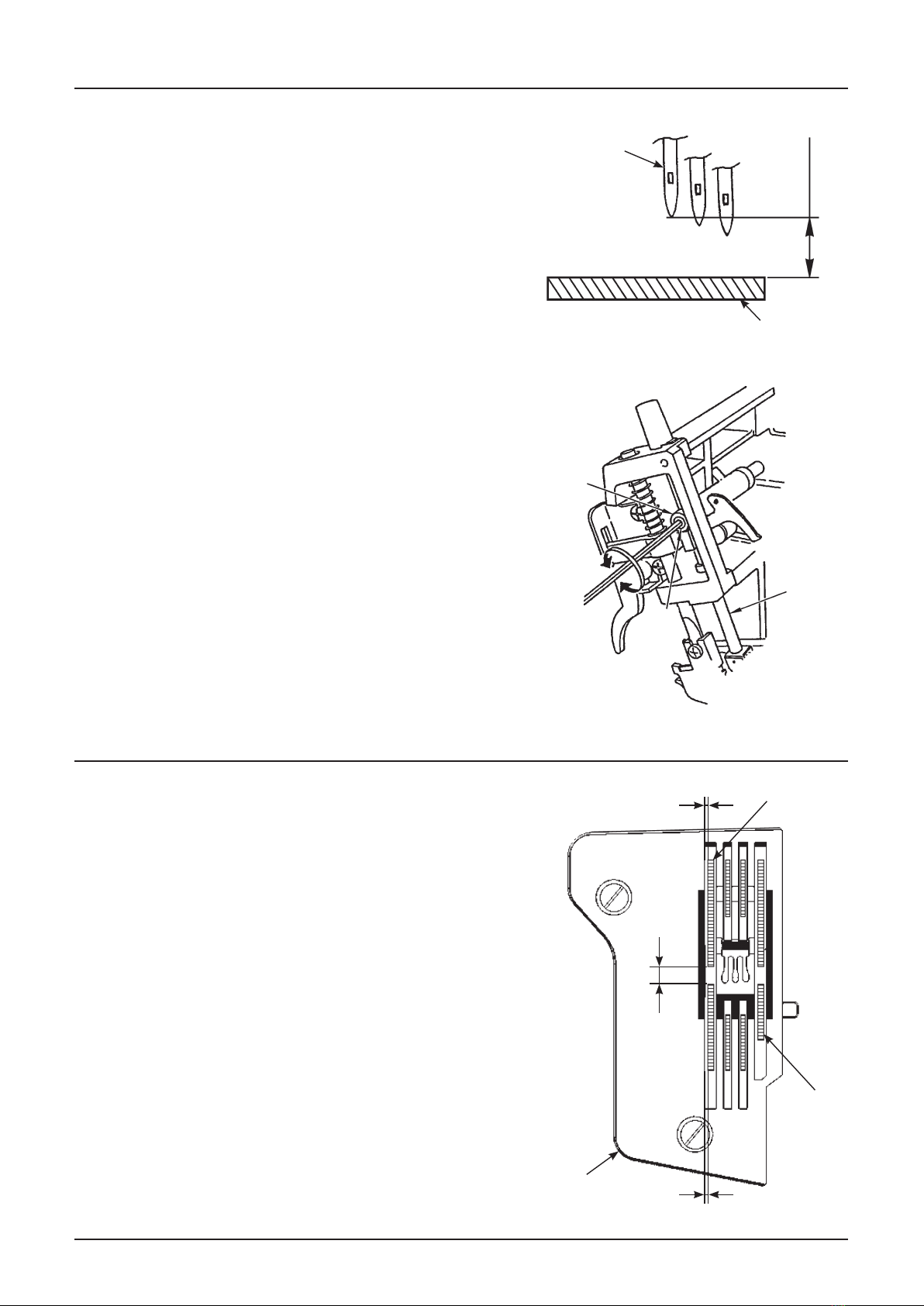

3.Positionofthefeeddog........................................................................................ 2

4.Heightofthefeeddog........................................................................................... 3

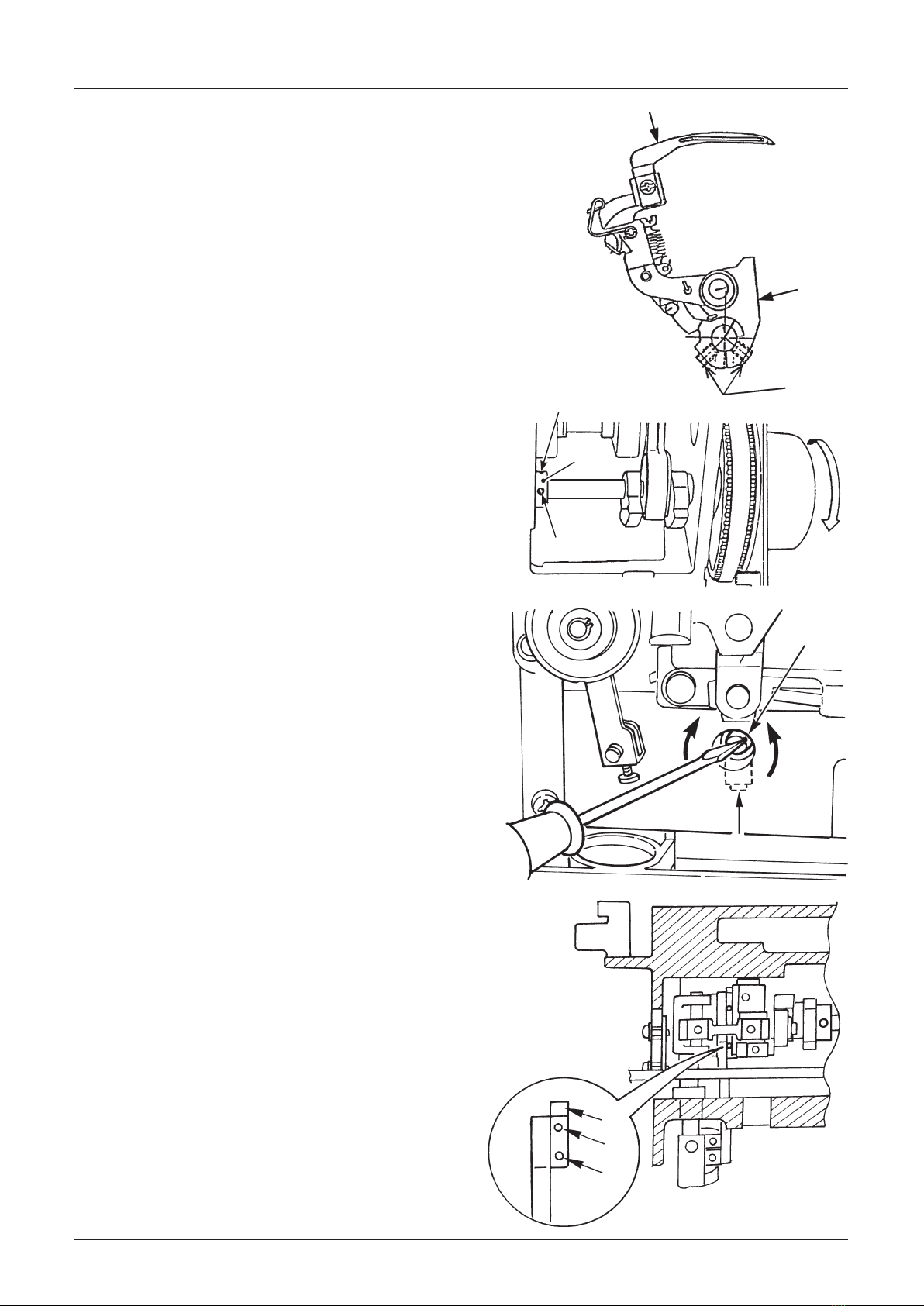

5. Feed dog timing..................................................................................................... 4

6.Positionofthebalanceweightsandcams ......................................................... 4

7.Radiusofthedouble-chainlooper....................................................................... 5

8.Adjustmentofthedouble-chainlooperandtheneedles................................... 5

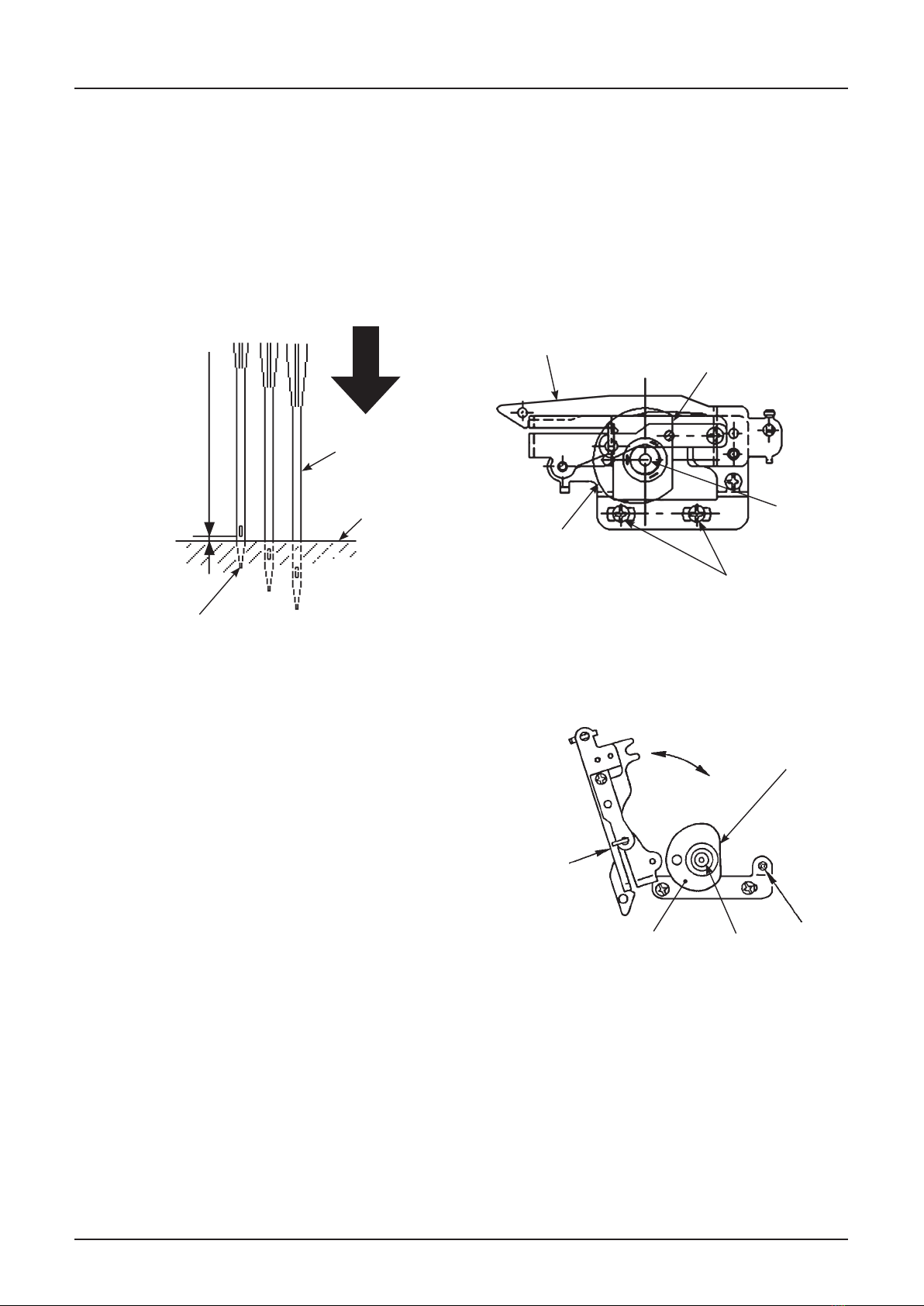

9.Installationoftheneedleguards.......................................................................... 7

10.Positionofthedouble-chainlooperthreadtake-up ........................................ 8

11.Positionofthedouble-chainlooperthreadtake-upguide.............................. 9

12.Positionofthetensionreleasemechanismofthetensioncontroller ........ 10

13.Heightandlateralpositionofthepresserfoot............................................... 11

14.Threadtensioncontrols.................................................................................... 12

15.Positioningthethreadtake-upspring............................................................. 13

WARNING :

Toavoidtheriskofre,electricshock,injurytopersonsordamagetocomponents,

especiallykeepthefollowing:

• When disassembling, assembling or adjusting the sewing machine, remove the power plug.

• When assembling, be careful about the electrical cord being caught with other components,

damage to the covered parts of the cord or miswiring.

• When replacing the part(s), use the genuine part(s).