Contents

1 Preface ............................................................... 3

1.1 Scope of delivery ..................................................................... 3

2 Identifying the instrument version ................... 4

3 Mounting ............................................................ 5

3.1 Preparation ............................................................................... 5

3.2 Fitting in position, Type 703042/43/44 .................................... 5

3.3 Fitting in position, Type 703041 ............................................... 5

4 Electrical connection ........................................ 6

4.1 Connection diagram for Type 703041 ..................................... 6

4.2 Connection diagram for Type 703042/43/44 ........................... 7

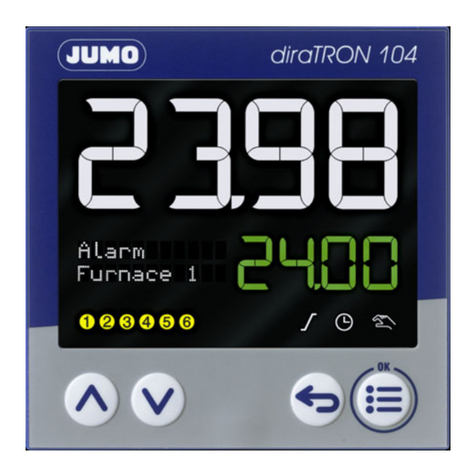

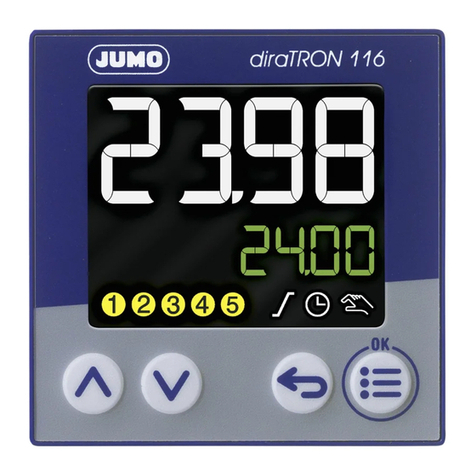

5 Displays and keys ............................................. 8

6 Operation ........................................................... 9

6.1 Level concept ........................................................................... 9

6.2 Level inhibit ............................................................................ 10

6.3 Entering values ....................................................................... 10

6.4 Entering times ........................................................................ 11

6.5 Operation of the fixed-setpoint controller .............................. 12

6.6 Operation of the program controller ...................................... 13

7 Operator level “OPr” ....................................... 14

8 Parameter level “PArA” .................................. 15

9 Configuration level “ConF” ............................ 16

9.1 Analog inputs “InP” ................................................................ 16

9.2 Controller “Cntr” ..................................................................... 17

9.3 Generator “Pro” ...................................................................... 17

9.4 Outputs “OutP” ...................................................................... 18

9.5 Display “diSP” ........................................................................ 19

10 Autotuning ....................................................... 20

11 Alarms .............................................................. 21