DN062-18v03

JYE Tech - 3 - www.jyetech.com

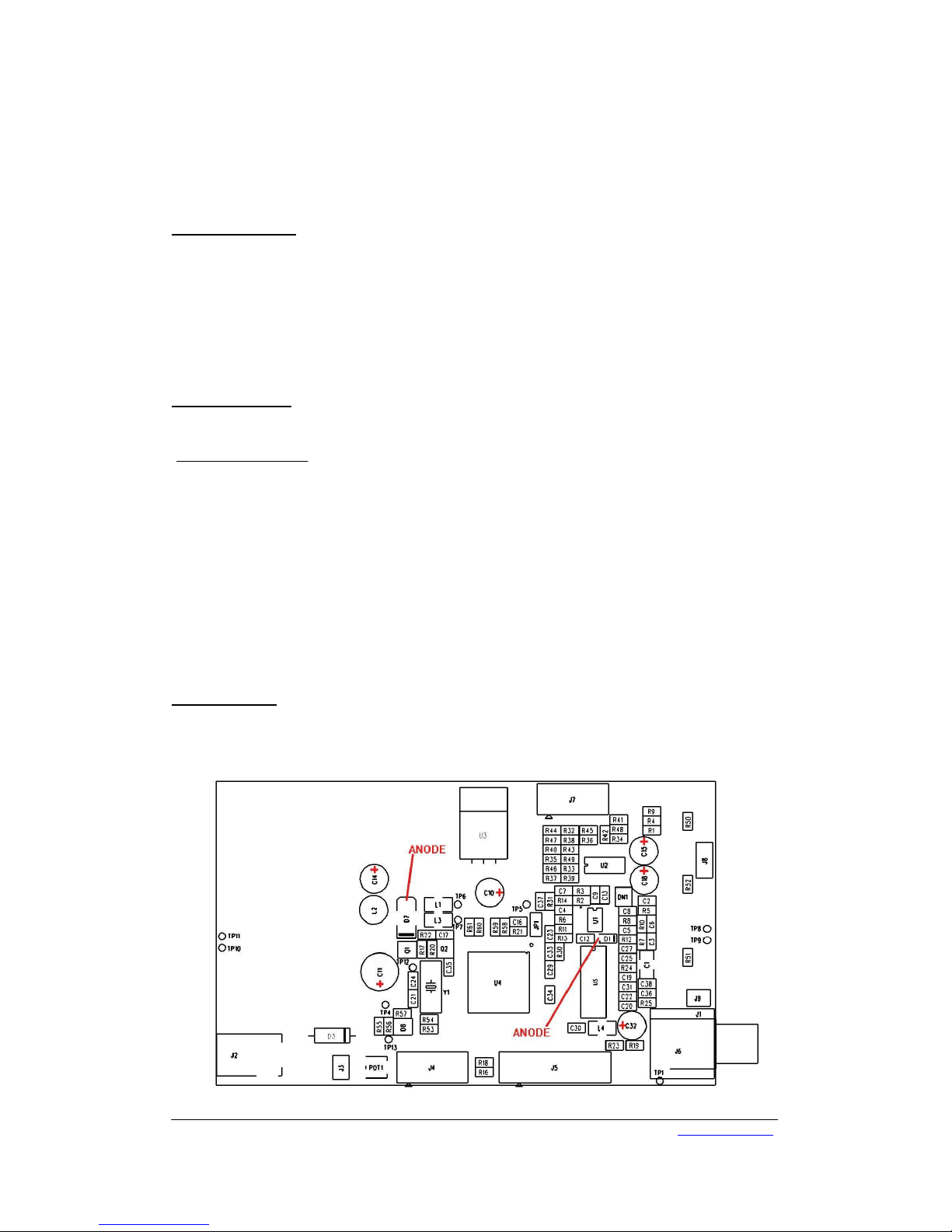

First mount heat sink (it is threaded) to PCB with provided M3 x10mm pan head

screw.Bend the leads of U3 properlyso that the leads go through the three soldering

holes and the hole at the tab fit the pan head screw.Tight U3 with the M3 nut firmly.

Solder its three leads at the other side.

Step 9. Check +5Vpowersupply

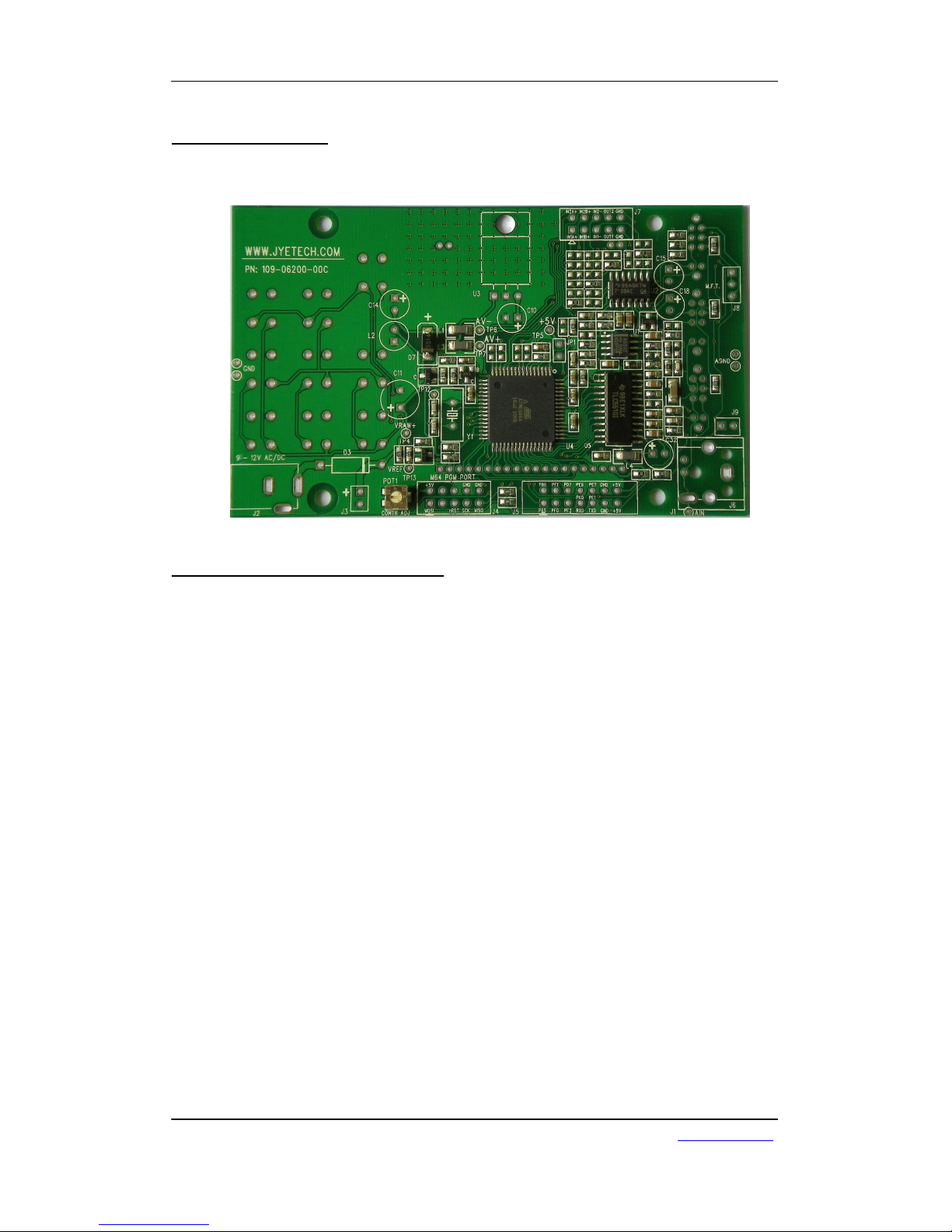

Now we have finished all through-hole part installation on the component side

(oscilloscope back side). Before proceeding tothe rest installation we shouldpower

the board and check if there are anymajor errors. You need a9 –12VDC power

supply.Please note thatthe center conductor of its plug shouldbe positive. Plug it

into J2 and measure voltage at TP5 with amulti-meter.The multi-metershould +5V

+/- 0.2V.If it is far from this value something is wrong. Please check D3, C11, C10,

and U3 soldering.

If voltage at TP5 tested ok then continue.

Step 10. Connect JP1

JP1 serves as asafeguard. It separates power supplyfrom the rest circuits to avoid

abnormal power supplyburns everything. Now that power supply is tested good JP1

can be hard connected with apiece of wire. After connecting JP1 check voltage at

TP5 again. There shouldbe not much difference from itsprevious value. If you find

it changed significantly that indicates something is wrong with the restcircuits. You

need to find out the causes before proceeding.

If the voltage at TP5 staysat +5Vthen you can continue toinstall components at the

front side of board

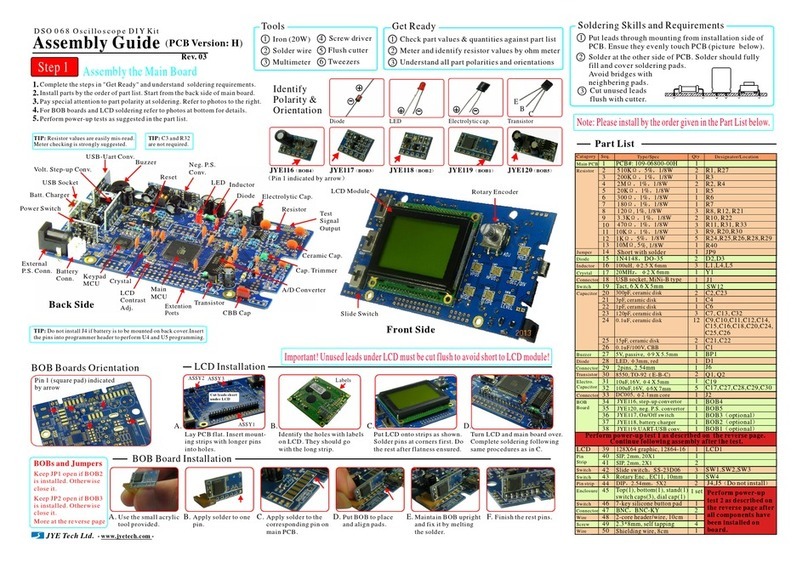

Step 11. Install tact switches

It is important to installall tact switches upright and evenlysit on PCB. Otherwise

you will have trouble in putting up the front panel later. We stronglyrecommend that

for each switch onlysolder two across pins the first time. Then check and if you find

switch position is uneven adjust it bytouching the soldered legs with an iron while

push it by hand on the other side. After you satisfy yourself with that all switches are

located properlysolder all the rest legs.

You need tobe alittle cautious when soldering SW11and SW12 since two of the

legs are prettyclose to C11. Tryto avoid damaging the coat of C11.

Step 12. Install slide switches

Again you need to make sure the three slide switches are soldered upright and sit

evenlyto avoid troublein front panel installing. After inserting switch into PCB

solder onlytwo pins first. Then check and adjust until no uneven is seen. Solder all

the rest pins.

Step 13. Install LCD module

First solder the long SIPpins (the 20x pin strip) to LCD module. Look at the LCD

module. You will see same number holes at two sides. Look for the holes with labels.

These are where the long SIPpins should go. [Do not solderit on theside without

labels!] Insert the shorter ends of the long SIPpins intoLCD modulefrom the side

opposite to the glass and solder its two end pins first. By only soldering two end pins

it will allow you have chance tocheck and adjust. The SIPpins need tobe installed

perpendicular to the LCDboard. Otherwise it will not fit the main board. After you

are sure of perpendicularityis guaranteed you can solder all the rest pins.

After the long SIPpins have been done follow the same wayto install the two short

SIPpins (2x pin strips). These two SIPpins are to be installed at the opposite ends of

other side. These pins are for holding the LCDmodule to the main board onlyand

are not part of the circuit. Again, theymust be perpendicular to the LCD board so

that the LCD can fit into the main board.

Important Note: Cut all C10 and U3 leads flash to PCB to avoid short to LCD

module.

Now place the assembled LCD module into the main board. Solder the four corner

pins first. Check to make sure the LCD assembly is fully inserted into the main board.