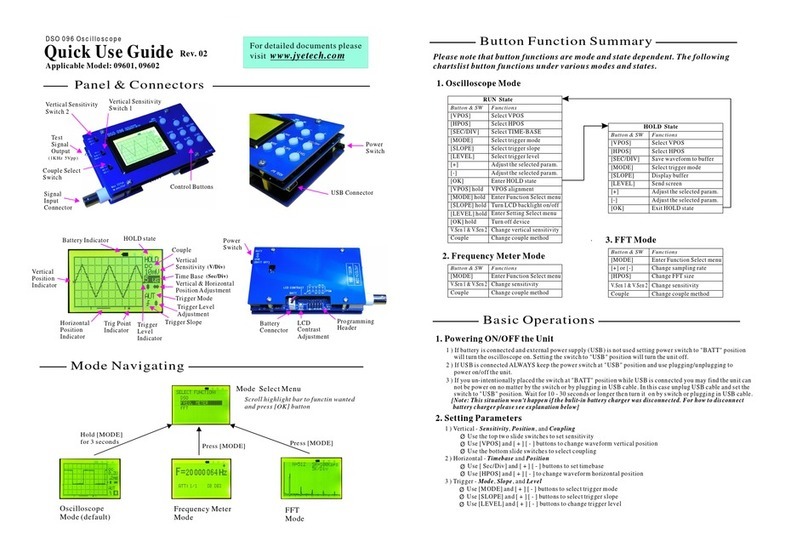

HOL D RUN/

Connec tors

for Pow er S upply

Trig ger Level

Rea d out

Horizontal

Positio n

Osc i ll osco p e

Mode

Connec tor

for Probe

Couple

Se l ection

Se nsiti vity

Se l ect ion 1

Sen s iti vity

Sel ection 2

Vertic al

Position

Indicator

Se nsitivi ty

Couple

Timeba se

Trigge r

Mod e

Trig ger

Slop e Trigg ed

Indicator

Trig ger

Leve l

Indicator

Parameter

Se l ection

Para m eter

Adjustment

Res et

Butt on

[+] or [-]:

[SEL]:

[OK]:

[CP L]:

[SEN1] :

[SEN 2]:

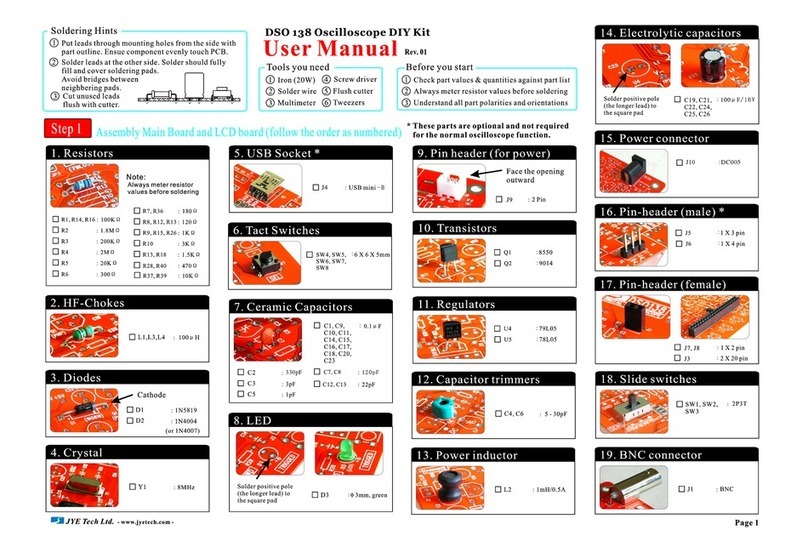

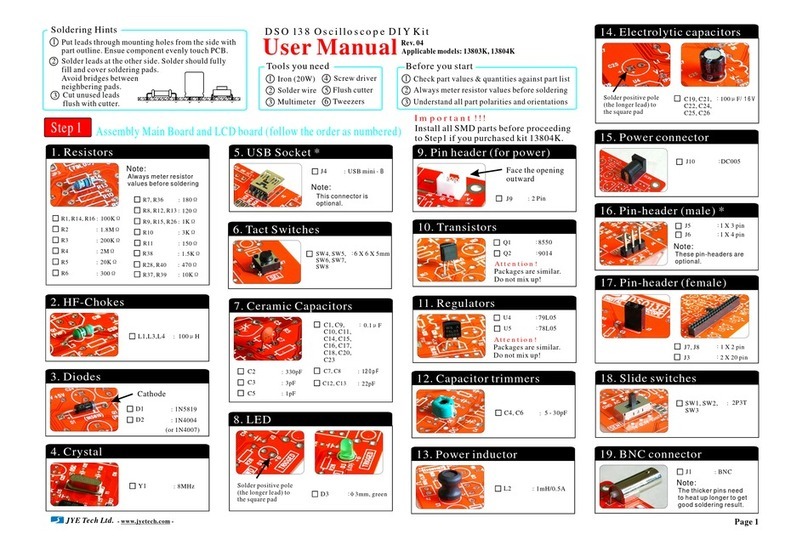

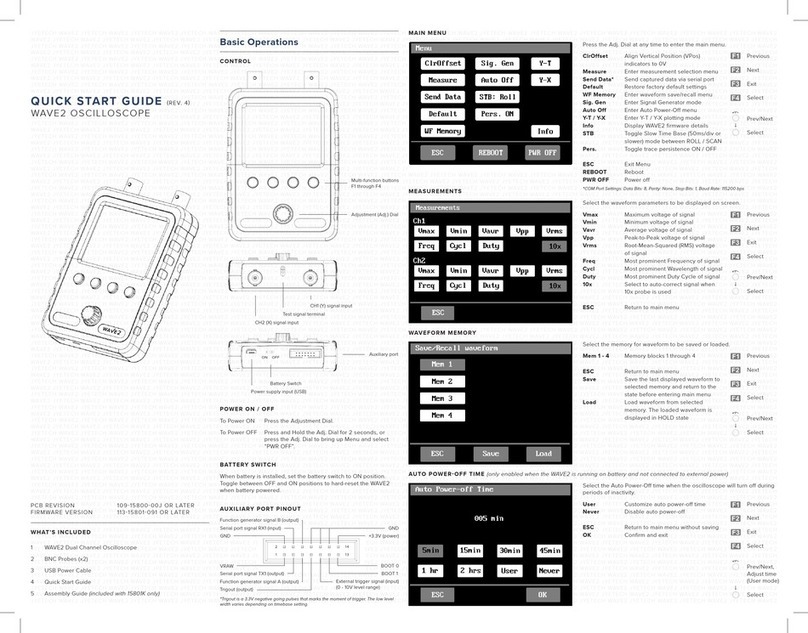

Display and Controls

Connections

Power Supply:

Co nnect DC power supply to J9 or J10. The power

supply voltage must be i n the range of 8 - 12V.

Probe:

Connect probe to J1.

Power supply voltage must not exc eed

12V. Otherwi se U5 will get hot.

1.

Allowed maximum signal input voltage

is 50Vpk (100Vpp) with the clip pro b e.

2.

Operations

Press on [SEL] button:

Select parameter to be adjusted. The sel ected parameter will be highlighted.

Press on [+] or [-] button:

Adjust the parameter selected by [SEL] button.

Press on [OK] button:

Freeze waveform refresh (entering HOLD state). Press on it again will de-freeze.

Change [CPL] switch:

Set couple to DC, AC, or GND. When GND is selected the scope input is isolated from input

signal and connected to ground (0V input).

Change [S EN1] or [SEN2] switch:

Adjust sensi tiv ity. The product of [SEN1] and [SEN2] settings makes the

actual sensitivity which is displayed at the lower-left corner of the panel.

Press on [Reset] button:

Perform a system reset and re-boots the oscillscope.

Tips

This is to fix the mismatch between 0V trace and VPos indicator. To do this set couple switch [CPL] to GND po sition.

Press on [SEL] button to make VPos indicator highlighed. Hold down [O K] button for about 2 seconds. You will see

VPos indicator aligned to 0V trace when you release [OK] button. You may see some residue mismatch remains at

the highes t sensitivity settings. This is normal.

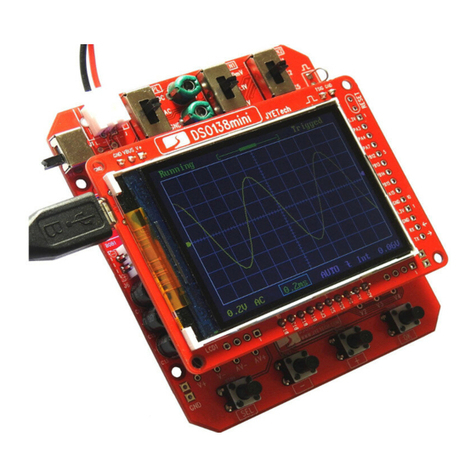

Probe Calibration

Because there is alwa ys some capacitance between scope input and

ground probe needs to be calibrated to achieve better measurement

results for high frequency signals. This can be done with the help of

the built-in test signal. To do this please fol low the steps below.

Connect red cli p to

test s ign a l output

Leave bl ack cl ip

un- con nected

Connect the red clip to the test signal terminal and le ave the

black clip un-connected (see p hoto at ri ght).

1.

Set [S E N1] switch to 0.1V an d [SEN2] switch to X5 .

Set [C PL] switch to AC or DC.

2.

Adjust timebase to 0.2 m s. You should see waveform similar

to that shown in photos below. If t races are not stable adjust

trigger lev el (the pink triangle on righ t screen border) so as

you get a stable display.

3.

Turn C4 (capacit or trim mer) with a small screw driver so that

th e waveform displays sharp rightangle (photo C).

4.

C4

C6

Set [SEN1] switch to 1V an d [SEN2] switch to X1while keep al l other

settin g s unchanged. Adjust C6 so that sharp rightang le waveform is

di splayed.

5.

A Not en ough B Too much C Good

Analog bandwidth

Se nsi tivity range

Resolution

Record length

Max realti me sampl e rate

Timebase range

Max input volta ge

Input impedance

Power supply

Current consumption

Dimension

Weight

1MSa/s

0 -- 200KHz

10mV/div - 5V /div

50Vpk (1X probe)

1M ohm/20pF

12 bits

1024 points

500s/Di v -- 10us/Div

9V DC (8 12V)

~120mA

117 x 76 x 15mm

70 gram (withou t probe)

Trigger mode s

Trigger position range

Auto, N ormal, and Singl e

50%

Specifications

Waveform Save/R ecall

Press [SEL] & [+] simultaneously: Save currently di splayed waveform to non-volatile memory.

www.jyetec h.com

JYE Tech Ltd.

Tel. +86-07 73-2113856

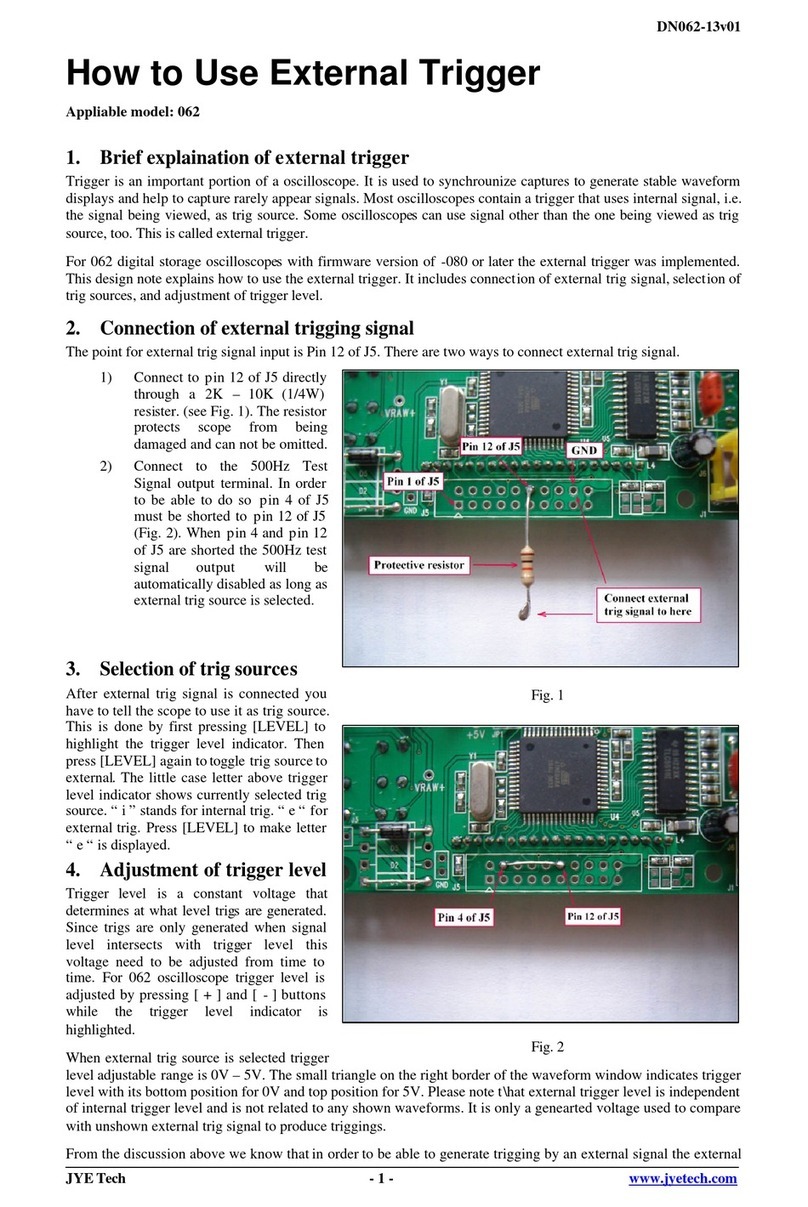

Triggers and Th eir Modes

Triggers are even ts that indicate signal volt age acrossing

a set lev el (i.e. trigger le vel) along a specified direction

(i.e. trigger slop e, rising or falling). Oscilloscope uses

triggers as reference poin ts in time for stab le waveform

dis play and measurements.

In aut o mo d e oscill oscope will perform disp lay refresh no

matt er triggers happen or not. When triggers are detected

waveform display will be dis p layed with reference to

trigger points. Otherwis e, disp lay waveform at ramdom

reference points.

In normal mode oscilloscope will onl y perform dis play

refresh whe n there are tri ggers. If no t rigg ers happen

waveform display will stay u nchan g ed.

Single mode is the sam e as normal mode except that

oscillo scope will enter HOLD state after a trigger has been

detected and waveform display has bee n up d ated.

Normal and single modes are us eful for capturing sparse

or single waveform.

Se l ection

(s/div)

(V/d iv )

Tech Support: www.jyetech.com/forum

Page 3

- www.jyetech.com -

JYE Tech Ltd.

Turn On/Off Readouts

Press [SEL] so that timebase is highlighted. Hold down [OK] button for ab out 2 seconds. This wi ll turn

on/off measurement readouts.

Press [SEL] & [-] simultaneously: Recall saved waveform

Hold down [+] and [-] buttons simultaneousl y for 2 seconds.

Highl ight trigger level indicator and hold down [O K] button for 2 seconds.Highl ight trigger level indicator and hold down [O K] button for 2 seconds.

Highl ight HPos indicator and ho ld down [OK] button for 2 seconds.