KTI63194A3

SETUP

PLEASE REFER TO THE EXPLODED VIEW DRAWING IN THIS MANUAL IN ORDER TO IDENTIFY PARTS.

1. Feedtheblackhose(#64)andorangehose(#63)comingoutofthebottomofthehandleassembly(#76)throughthehandle-1(#52)whileat

thesametimelininguptheholeinthehandle-1(#52)withtheholeinthehandleconnector(#55).Securethemtogetherwiththescrew(#54).

2. Threadtwonuts(#53)allthewayonthebottomofthetierod(#50).Threadthebottomofthetierodallthewayinsidetheslottedpin

(#49).Nowtightenonenut(#53)downontopoftheslottedpin(#49)andtighten.Slipthespring(#51)downonthetierod(#50).Insertthe

tierod(#50)throughthebottomofthebracketthatisweldedtothehandle-1(#52)sothatthespringistrappedbetweenthebracketand

thenuts(#53)thataretightenedagainsttheslottedpin(#49).Compressthespringuntilthecrossholeinthetierod(#50)isvisibleonthe

othersideoftheweldedbracketandinstallther-pin(#71)throughthehole.

3. Threadanothernut(#53)allthewayonthetierod(#56).Holdthehandlelock(#58)downandawayfromthet-handle-2(#60)while

simultaneouslythreadingthetierod(#56)nutontothetierod(#50).

4. Raisethehandlelock(#58)upsotheslottedpin(#49)doesnotcomeincontactwithanyofthethreeholesinthehandleposition

seatassembly(#7).Removethescrew(#73)fromthehandlesocket(#11).Insertthehandle-1(#52)inthehandlesocket(#11)while

simultaneouslyinsertingtheslottedpin(#49)inthehandlesocket(#11)guideholes.Makesuretheholeinthelowerportionofthe

handle-1(#52)alignswiththethreadedholeinthehandlesocket(#11)andsecurethemtogetherwiththescrew(#73).Movethehandle

upanddownwhilesimultaneouslypullingthehandlelockdownsotheslottedpin(#49)willengagewithanyofthethreelockingholesin

thehandlepositionseatassembly(#7).Makesuretheslottedpinwillengageallthreeholes.Itmightbenecessarytoadjustthethreaded

connectionbetweentierods(#50and#56)inordertogetproperengagement.Afternaladjustment,tightenthenut(#53)tosecurethe

connection.

5. Therearetwoairhosesthatmustbermlyinsertedintothecouplers(#48).Theorangehose(#63)tsinthehigherlocatedcouplerwhile

theblackhose(#64)tsinthelowerlocatedcoupler.

6. Installtheairquickdisconnectofyourchoiceinthecrossvalve(#65).Putatleasttwowrapsofpipedopetapearoundthedisconnect

threads before installation to prevent air leaks.

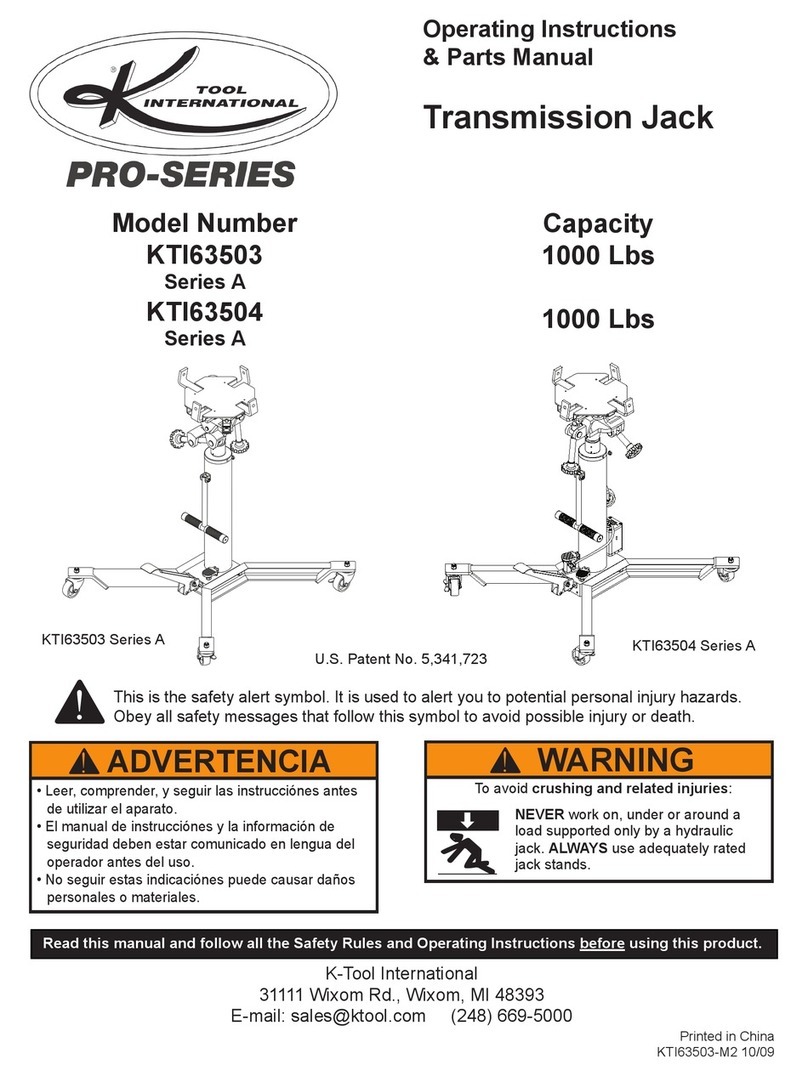

7. Installthebracketassembly(#72)onthehandle-1tubeinthepositionasshownonthecoveroftheOwner’sManualandsecurethe

adaptorsinthebracketholesusingther-pins(#69).

8. Duetothevacuumreleasesystemdesignofthisjack,thejack’shydraulicsystemveryrarelybecomesairbound.Indicationofanair

bound system is a ram that does not rise smoothly. In some extreme case of an air bound system, air can be purged by following this

procedure:

PURGING AIR FROM THE HYDRAULIC SYSTEM

a. Raisetheram(#32)tomaximumheightandthenloweritallthewaydownfollowingtheactivationdirectionsontopofthehandle.

b. Repeatstep“a”severaltimesuntilallairispurgedfromthesystem.

OPERATING INSTRUCTIONS

This is the safety alert symbol used for the OPERATING INSTRUCTIONS section of this manual to alert you to potential

personal injury hazards. Obey all instructions to avoid possible injury or death.

IMPORTANT: Before attempting to raise any vehicle, check vehicle service manual for recommended lifting surfaces.

1. Becomefamiliarwiththeidenticationandfunctionoftheoperatingjackcomponents.

a. The ram

(#32)

is the shaft that comes out of the jack when you rotate the air lever to the right.

b. The ram

(#32)

is equipped with an extension screw which can be unscrewed to extend from the ram if there is not enough hydraulic

stroke to raise the load to the desired height. If additional height is required, extension adapters can be inserted in the hole on top of

the extension screw.

c. Largerdiametersaddlescanbeinsertedintheextensionscrewwhenrequiringalargerdiametersaddlesurface.

2. Chockthevehicle'stiresthatwillnotbeliftedoffthegroundpriortoliftingthevehicleandifavailable,applytheemergencybrakeorany

other method of braking.

3. Positionthejackatthedesignatedliftpoint.Estimatetherequiredramtraveltoraisethevehicletothedesiredheight.Ifthedesired

vehicle height exceeds the entire ram travel, unscrew the extension screw to make up the difference and add an extension adapter if

necessary.

4. Lockthehandleinapositionthatwillnotinterferewiththevehiclewhenraisedorlowered.Keepthehandleinthatlockedpositionuntil

the work is completed and you are ready to remove the jack from use.

5. Withthejackintheloweredposition,pushthejackunderthevehicle.IMPORTANT:Usethevehiclemanufacturer'srecommendedlifting

procedures and lifting points before lifting loads.

6. Inmostcases100psiginputairpressure(donotexceed200psig)willliftthemaximumcapacityloadnottoexceed22tons.Rotatethe

air lever to the right until the top of the ram comes close to the designated lift point. Make sure the designated lift point is at, parallel

tothegroundandfreefromgrease,anykindoflubricant,anddebris.Proceedwithpumpingthejackinordertoliftthevehicletothe

desiredheight.Duringlifting,inspectthepositionofthejackinrelationtothegroundandtheraminrelationshiptotheloadtopreventany

unstable conditions from developing. If conditions look like they are becoming unstable, slowly lower the load and make appropriate setup

corrections after the load is fully lowered.

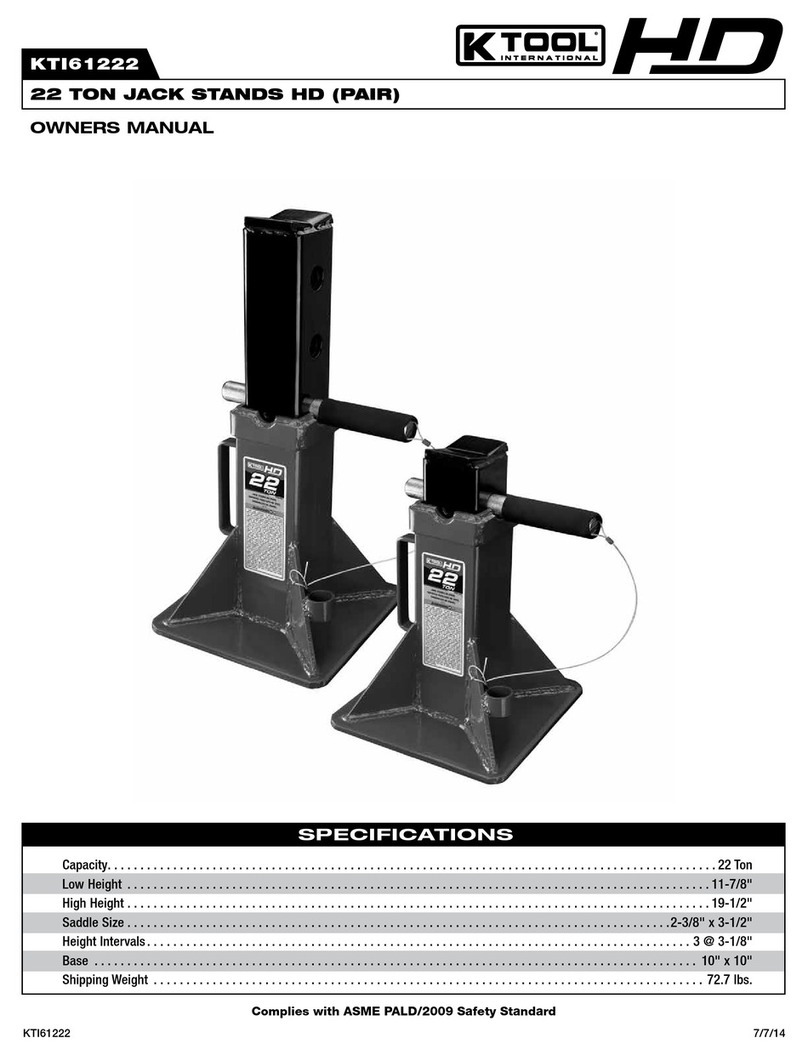

7.Whenthevehicleorloadisliftedtoitsdesiredheight,immediatelyplacesafetysupportstands(jackstands)intheirdesignated

locationsandadjustthestands'supportcolumnsupasclosetothedesignatedvehiclesupportpointsaspossible.Althoughjack

standsareindividuallyrated,theyaretobeusedinamatchedpairtosupportoneendofthevehicleonly.Standsarenottobeused

tosimultaneouslysupportbothendsoronesideofavehicle.Rotatetheairlevertothelefttolowerthevehicleontothesafetysupport

stands(jackstands).Makesurethevehicleissafelysupportedbythesafetysupportstands'(jackstands)saddlesandnotthelocating

lugsofthesaddles.Inspecttherelationshipofthesafetysupportstands(jackstands)withthegroundandthesafetysupportstand(jack

stand)columnsandsaddleswiththevehicletopreventanyunstableconditions.Ifconditionslookunstable,rotatetheairlevertotheright

toraisethevehicleoffthesafetysupportstands(jackstands).Maketheappropriatesetupchangesandslowlyandcarefullylowerthe

vehicle onto the safety support stand saddles.

8. Aftertheworkisdone,rotatetheairlevertotherightuntilthejackishighenoughtoremovethevehicleorloadfromthesafetysupport

stand saddles. Be sure load is stable. If it is not, lower load back onto safety support stands. Make appropriate setup corrections and

repeatthestepagain.Removethesafetysupportstandsfromunderthevehicle,beingverycarefulnottomovethevehicle.

9. Rotatetheairlevertothelefttolowerthevehicleorloaddowntotheground.