Part I: Install Front Housing Assembly

1. Route the end of the lock

cable with the Picoflex connector

from the back of the container

door through the cable routing

hole. (Figure 4)

2. Remove the front cover from

the keypad/base assembly.

3. Hold the keypad/base

assembly in the upright position

(i.e., the keypad is positioned at

the top) and hold the

keypad in place. Guide the

cable through the cable

receiving hole from the back

of the keypad/base

assembly. (Figure 5)

4. Route the lock cable

toward the keypad so that

the cable will not be pinched

by the generator. Gently lift

the keypad board assembly

and guide the cable up

through the cable receiving

hole in the keypad/base

assembly. (Figure 5)

5. Insert the Picoflex connector

on the end of the ribbon cable

into the header on the keypad

with proper orientation. (Figure

6)

6. Insert the spindle from the

back of the keypad/base

assembly. (Figure 7)

7. Position the keypad/base

assembly firmly against the

container door and attach it to the

container door using the two #8-

32 (or M4-0.7) keypad/base

assembly mounting screws. (Figure

8) Do not fully tighten screws.

8. Position the cable and the

keypad so that they will not be

pinched when the front cover is

snapped into place.

9. Pull excess cable through to

the inside of the container.

10. Tighten the keypad/base

assembly mounting screws.

(Torque 17-20 lbs., 1.9-2.25 N-M)

(Figure 8)

11. Center the front cover over

the keypad/base assembly and

gently snap into place.

12. Mount the front cover to

the keypad/base assembly

using the round mounting holes

on the cover and the three #6-

32 mounting screws. (Torque 14-

16 lbs., 1.6-1.8 N-M) (Figure 9)

13. Place the nylon dial spacer

over the spindle.

14. Place the dial onto the

spindle and seat into the dial

bushing. Push gently on the dial

so that the gear on the

generator seats properly into the

gear teeth on the dial.

15. Plug the RJ11 end of the cable into the lock case in order to test

the lock.

16. Test the operation of the lock before completing the installation of

the front cover by verifying the following:

• Ensure that the dial turns freely without scraping.

• Power the lock by turning the dial briskly in any direction until

simultaneous green and red flashes display and two beeps sound to

indicate the lock is powered. Key in the Factory Combination. (For a

Model 52 or T52, enter “502550”. For a Model 252 or 552, enter a two-

digit number in the range from 01-20, followed by “502550”.) If the

combination is entered successfully, continuous green flashes display

to indicate that the lock is ready to open. Rotate the container handle

to unlock. Then rotate the handle back to the locked position.

Note:

After correctly entering a valid combination, you must

retract the bolt within 4-6 seconds.

17. Unplug the RJ11 end of the cable from the lock case and lay the

case aside.

18. After successfully testing lock operation, hold the cover assembly

in place and remove the dial.

19. Apply a small amount of lubricant to the gear on the generator,

the bearing surface of the dial (the portion that fits into the dial bushing

of the base assembly), and the teeth around the edge of the dial.

20. Place the dial onto the spindle and seat into the dial bushing.

Push gently on the dial so that the gear on the generator seats

properly into the gear teeth on the dial.

21. Insert the #4-40 dial mounting screw through the metal dial

mounting washer. Then insert the dial mounting screw/washer

assembly into the spindle and tighten the dial mounting screw.

Caution:

To meet the requirements of certain approval agencies, a

tamper evident dial label may have been included with your lock. It is

important that the next step of the installation be completed very

carefully, allowing the dial label to be applied correctly on the first

attempt. If the tamper evident dial label is removed after initial

application, a part of the label will stay on the dial. A new label would

then be required for reapplication.

22. Orient the lip of the dial to

the upright position and apply

the dial label to the dial. The

Kaba logo should be aligned

horizontally (Figure 10).

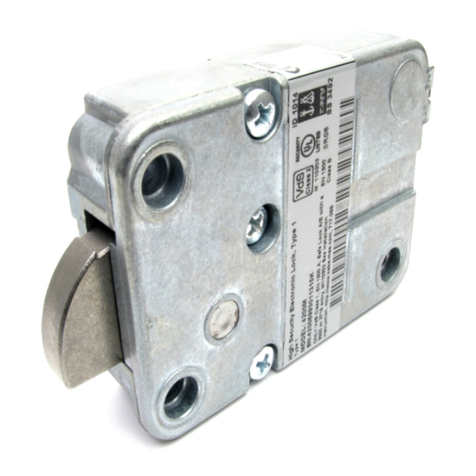

Part II: Install Lock Case Assembly

WARNING:

Do not take the lock case assembly apart. The lock

will not operate if the back cover has been removed.

1. Ensure that the cable lays in the cable channel as you mount the

lock case assembly to the inside of the container door using the three

1/4-20 (or M6-1) screws (Torque 25-30 lbs., 2.8-3.4 N-M), allowing 1/16”

(1.588mm) clearance between the lock bolt and the container locking

bar. (See Figure 2 for proper clearances and positioning when

installing a square nose slide bolt. See Figure 3 for proper clearances,

strike types and contact points when installing a roller slide bolt.)

Note:

The lock case

assembly can be mounted

in bolt roller up position or

bolt roller down position

(Figure 11) for all mounting

locations. It is recommended

that you use Loctite

®

262

(Red) on the lock case

mounting screws.

2. If your lock includes the

Battery Assist option, you

should now mount the battery clip

inside the door near the lock and

install a fresh 9 Volt Alkaline

battery.

Note:

To remove any excess

cable or if you choose not to use

the Battery Assist option, wrap

and tie the battery assist cable.

(Figure 12) If you do not ever

plan on using the Battery Assist

option, you can cut the cable

next to the lock case to remove it.

Figure 10

© 2005-2006 Kaba Mas Corporation. All rights reserved.

Product warranty information can be found at: www.kaba-mas.com

Kaba Mas Corporation

749 W. Short Street, Lexington, KY 40508 USA

Phone: (859) 253-4744 FAX: (859) 255-2655

Customer Service: (800) 950-4744

Figure 4

Figure 8

Figure 6

Connection

Header

Spindle

Figure 7

Figure 9

Figure 11

Lip of

Dial

Generator

Cable Rcv

Hole

Figure 5

Figure 12