TDLG_A-BA-e-2011 3

9SETUP MENU................................................................................................... 26

9.1 Navigation in the menu...................................................................................................... 26

9.2 Description of individual functions.................................................................................. 27

9.2.1 User language...................................................................................................................... 27

9.2.2 Setting time and date ........................................................................................................... 28

9.2.3 Switch on and off the background illumination .................................................................... 28

9.2.4 Setting the contrast of the display........................................................................................ 29

9.2.5 Weighing unit [g / mg] .......................................................................................................... 29

9.2.6 Auto zero.............................................................................................................................. 30

9.2.7 Setting the filter .................................................................................................................... 31

9.2.8 Setting the stability............................................................................................................... 32

10 APPLICATION MENU <MOISTURE ANALYSIS>........................................ 33

10.1 Settings of the heating module......................................................................................... 34

10.1.1 Setting the heating profile................................................................................................ 35

10.1.2 Connect the preheating stage.......................................................................................... 36

10.1.3 Start mode ....................................................................................................................... 37

10.1.4 Start delay........................................................................................................................ 38

10.1.5 Stability test...................................................................................................................... 38

10.2 GLP settings....................................................................................................................... 39

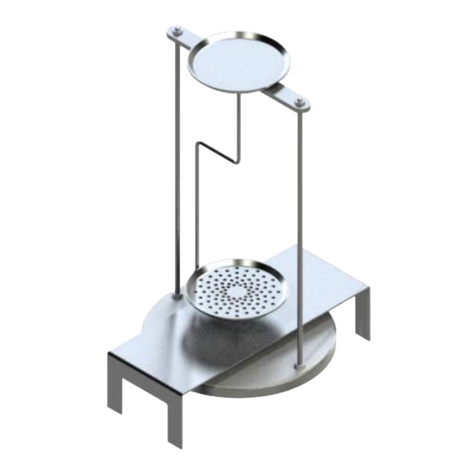

11 MOISTURE ANALYSIS................................................................................. 40

11.1 Define the drying method.................................................................................................. 40

11.1.1 Setting the drying temperature ........................................................................................ 40

11.1.2 Adjust the switch-off criterion........................................................................................... 41

11.2 Carrying Out Measurement............................................................................................... 42

11.3 Sample logs (KERN YKB-01N).......................................................................................... 44

11.4 Results display................................................................................................................... 46

12 RS 232 INTERFACE ..................................................................................... 47

12.1 Technical data .................................................................................................................... 47

12.2 Adjusting the interface parameters.................................................................................. 47

12.2.1 Setting the output interval................................................................................................ 48

12.2.2 Select printer type............................................................................................................ 49

12.2.3 Setting the baud rate ....................................................................................................... 49

12.2.4 Turn on/off GLP function.................................................................................................. 50

13 GENERAL INFORMATION CONCERNING MOISTURE ANALYSIS........... 51

13.1 Application.......................................................................................................................... 51

13.2 Basics.................................................................................................................................. 51

13.3 Drying process................................................................................................................... 51

13.4 Comparison with a reference procedure......................................................................... 52

13.5 Handling samples .............................................................................................................. 52

14 SERVICING, MAINTENANCE, DISPOSAL .................................................. 56

14.1 14.1 Cleaning...................................................................................................................... 56

14.2 Servicing, maintenance..................................................................................................... 56

14.3 Disposal .............................................................................................................................. 56

15 INSTANT HELP............................................................................................. 57