Kleinn GMHD20-OBA User manual

Install Guide GMHD20-OBA

Page | 2 Revision: A

Table of Contents

1. Application Chart .................................................................................................................................. 4

1.1. List of compatible vehicles............................................................................................................ 4

1.2. Incompatible Vehicle Features & Packages .................................................................................. 4

1.3. Aftermarket Product Compatibility .............................................................................................. 4

2. Before You Start.................................................................................................................................... 5

3. Installation Overview ............................................................................................................................ 5

3.1. Kit Layout & Location.................................................................................................................... 5

4. List of Tools & Supplies ......................................................................................................................... 6

4.1. Standard Tools .............................................................................................................................. 6

4.2. Specialty Tools .............................................................................................................................. 6

4.3. Consumables................................................................................................................................. 6

5. Parts List................................................................................................................................................ 7

5.1. Primary Kit Components ............................................................................................................... 7

5.2. Fittings & Related Items................................................................................................................ 8

5.3. Electrical Components & Related Items ....................................................................................... 9

5.4. Mounting Brackets........................................................................................................................ 9

5.5. Hardware & Related Items.......................................................................................................... 10

6. Recommended Routing of Air Tubing & Wire ....................................................................................11

7. Bench Assembly .................................................................................................................................. 12

7.1. Rubber Trim – Cutting & Installation ..........................................................................................12

7.2. Air Tank – Fitting Installation ......................................................................................................13

7.3. Compressor – Fitting Installation................................................................................................ 13

7.4. INF-1 – Fitting Installation........................................................................................................... 13

8. On-Vehicle Assembly ..........................................................................................................................14

8.1. Compressor Installation..............................................................................................................14

8.2. Tank Installation.......................................................................................................................... 18

8.3. Air Tank Installation ....................................................................................................................21

8.4. 1302 Remote Air Quick Connect.................................................................................................22

8.5. Final System Plumbing ................................................................................................................22

9. On-Vehicle Electrical Installation ........................................................................................................23

9.1. Solenoid Connector – Reconfigure the Housing & Wiring..........................................................23

9.2. Attach Relay & Fuse to Vehicle ................................................................................................... 24

Install Guide GMHD20-OBA

Page | 3 Revision: A

9.3. Install Horn Button...................................................................................................................... 24

9.4. Route Wiring & Make Connections.............................................................................................25

10. Testing the Air System ....................................................................................................................26

10.1. Air Compressor Test................................................................................................................26

10.2. Air Horn Test ...........................................................................................................................26

10.3. Quick Connect Coupler Test.................................................................................................... 26

11. Maintenance ...................................................................................................................................27

12. Warranty Information.....................................................................................................................28

Install Guide GMHD20-OBA

Page | 4 Revision: A

1. Application Chart

This kit is a direct bolt-on aftermarket product. The vehicles listed in the below table are considered to

be compatible with this aftermarket kit. Every effort has been made to verify fitment on these vehicles

in their factory condition.

WARNING: Before unpacking your kit, review this manual in full & verify the correct space & mounting

locations exist with your trim package.

1.1. List of compatible vehicles

Year

Make

Model

Drivetrain

Engine

Cab

Bed

Trim

2020 + Chevy

Silverado

2500HD

2WD

4WD

Vortec 6.6L

Duramax 6.6L Crew

Standard

Long

Work Truck

Custom

LT

LTZ

High Country

Silverado

3500HD

2020 + GMC

Sierra

2500HD Standard

Long

Pro

SLE

SLT

AT4

Denali

Sierra

3500HD

NOTE: Drilling holes may be required for installing ground wires and switches based on the installer’s

preference.

1.2. Incompatible Vehicle Features & Packages

This kit is NOT COMPATIBLE with the following vehicle features / packages:

•N/A

1.3. Aftermarket Product Compatibility

This kit has been designed to be compatible with the following products from leading manufacturers:

•AMP Research PowerSteps

oThe tank must be positioned further back on the mounting bracket to avoid interference with

the PowerSteps Motor. This adjustment blocks the mounting point for the nearby electrical

connector. The connector may be secured by alternate means.

This kit has not been designed to be compatible with the following products:

•Aftermarket running boards that utilize 4 mounting locations along the vehicle frame rails

•Carhartt Edition

•Z71 Sports Edition

•Midnight Edition

These packages utilize running boards which contain

one (1) mounting location that interferes with the

placement of the air tank. It may be possible to

remove the interfering mounting bracket and install

this aftermarket kit.

Install Guide GMHD20-OBA

Page | 5 Revision: A

2. Before You Start

Read this manual in its entirety before starting installation. Verify you have all the parts listed & that you

clearly understand the installation procedure. Contact KLEINN Technical Support with any questions you

may have.

Installation of this kit requires moderate mechanical aptitude.

Use the proper tools, supplementary lighting, and safety equipment when installing this kit.

3. Installation Overview

3.1. Kit Layout & Location

Item

No. Description Mounting Location

Approx.

Install

Time

1 6450RC Air Compressor

Along the passenger side frame rail, between

driver & passenger door

1 Hour

2

6353RT Air Tank

On the driver side frame rail, below the rear door

1 Hour

3

1302 Relocation Kit

TBD by Installer/Customer (Not Illustrated)

N/A

Note: Wiring time is not factored into the overall install time of this kit. See Section 6 for suggested

wiring & plumbing routes.

Figure 1- Kit Layout

Install Guide GMHD20-OBA

Page | 6 Revision: A

4. List of Tools & Supplies

4.1. Standard Tools

•Mechanic’s 1/4" & 3/8” Drive & Socket Set – Imperial & Metric

•Combination wrenches – Imperial & Metric

•Hex wrenches – Imperial & Metric

•Screwdriver Set – #1, #2

•Wire Cutters

•Wire Strippers

•Wire Crimpers

•Utility Knife or Equivalent

•Precision Screwdriver or Small Pry Tool

4.2. Specialty Tools

•1/4” & 3/8” Universal Joints

•1/4" & 3/8” Extensions

•Multimeter, Test Light, or Equivalent

•Heat Gun

•Trim Panel Removal Tools

•Drill Driver & Bits

•Impact Driver & Bits

•Wire Running Kit or Equivalent

4.3. Consumables

•Quality Electrical Tape

•Medium Strength Thread Locker

•Sandpaper, Wire Brushes or Equivalent

•Extra Zip Ties

•Touch-up Paint

Install Guide GMHD20-OBA

Page | 7 Revision: A

5. Parts List

Unpackage & organize the kit contents and verify all parts listed below are included. Contact KLEINN

Support if any questions arise.

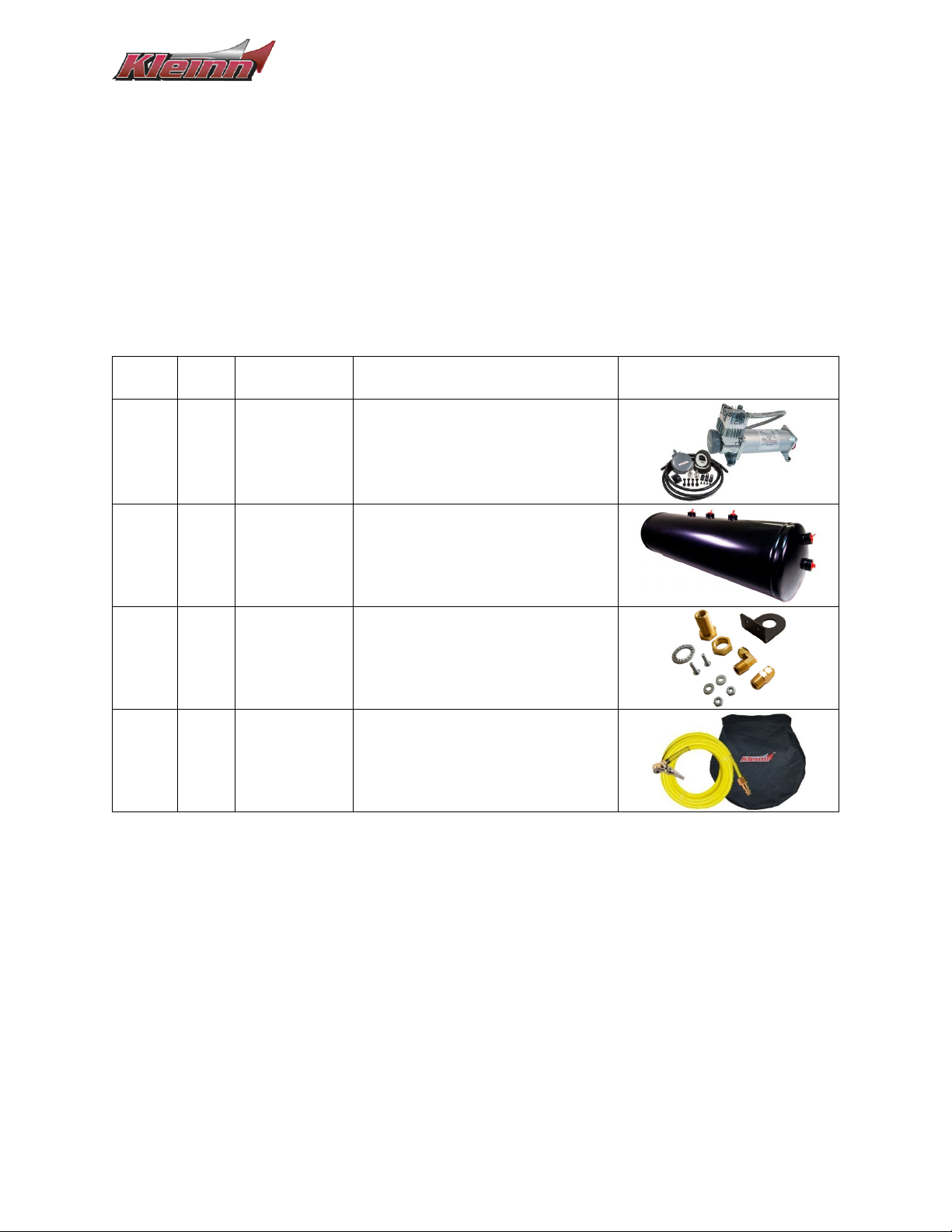

5.1. Primary Kit Components

NOTE: Items in this section may come in their own packages which may include additional items,

hardware, or documentation.

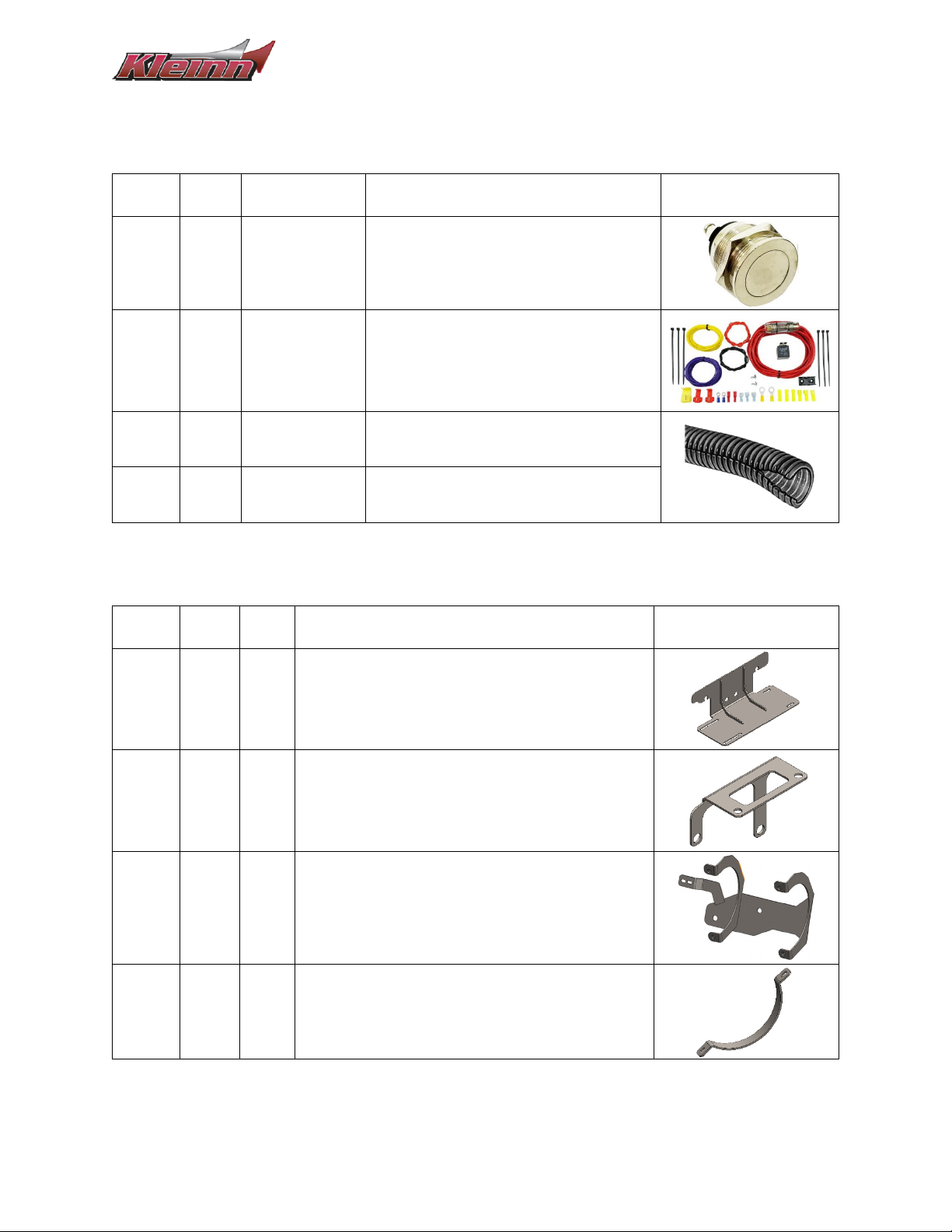

Item

No.

Qty Part No. Description Picture

1.

1 6450RC 150 PSI Waterproof Air Compressor

Kit

2.

1 6353RT 2.6 Gal. Air Tank, 9-Port

3.

1 1302 Quick Disconnect Air Relocation Kit

NOTE: May be located within INF-1 Kit

4.

1 INF-1 Tire Inflator Kit

Install Guide GMHD20-OBA

Page | 8 Revision: A

5.2. Fittings & Related Items

Item

No.

Qty Part No. Description Picture

F1

1 51414F ¼” NPT Female to ¼” Compression

F2

1 51414L ¼” NPT Male to ¼” Compression,

Elbow

F3

1 51414NPTL ¼” NPT Male to ¼” NPT Female,

Elbow

F4

1 52175 175 PSI Pop-Off Safety Valve

F5

4 50040 ¼” NPT Male, Hex Plug

F6

1 52835 ¼” NPT Male Drain Plug

F7

1 2151 Pressure switch,

110 PSI On – 145 PSI Off

F8

12 ft

&

12 ft

25014 1/4" Air Tubing

NOTE: May be located within INF-1 Kit

F9

2 JUICE NPT Thread Sealant

Install Guide GMHD20-OBA

Page | 9 Revision: A

5.3. Electrical Components & Related Items

Item

No.

Qty Part No. Description Picture

-

1 320 Momentary Switch, NO

-

1 N/A Wire Kit

-

30 ft N/A 3/8” Loom Pack

-

10 ft N/A 1/4" Loom Pack

5.4. Mounting Brackets

Item

No.

Qty

Part

No.

Description Picture

-

1 - Compressor Bracket

-

1 - Module Relocation Bracket

-

1 - Tank Bracket

-

2 - Tank Strap

Install Guide GMHD20-OBA

Page | 10 Revision: A

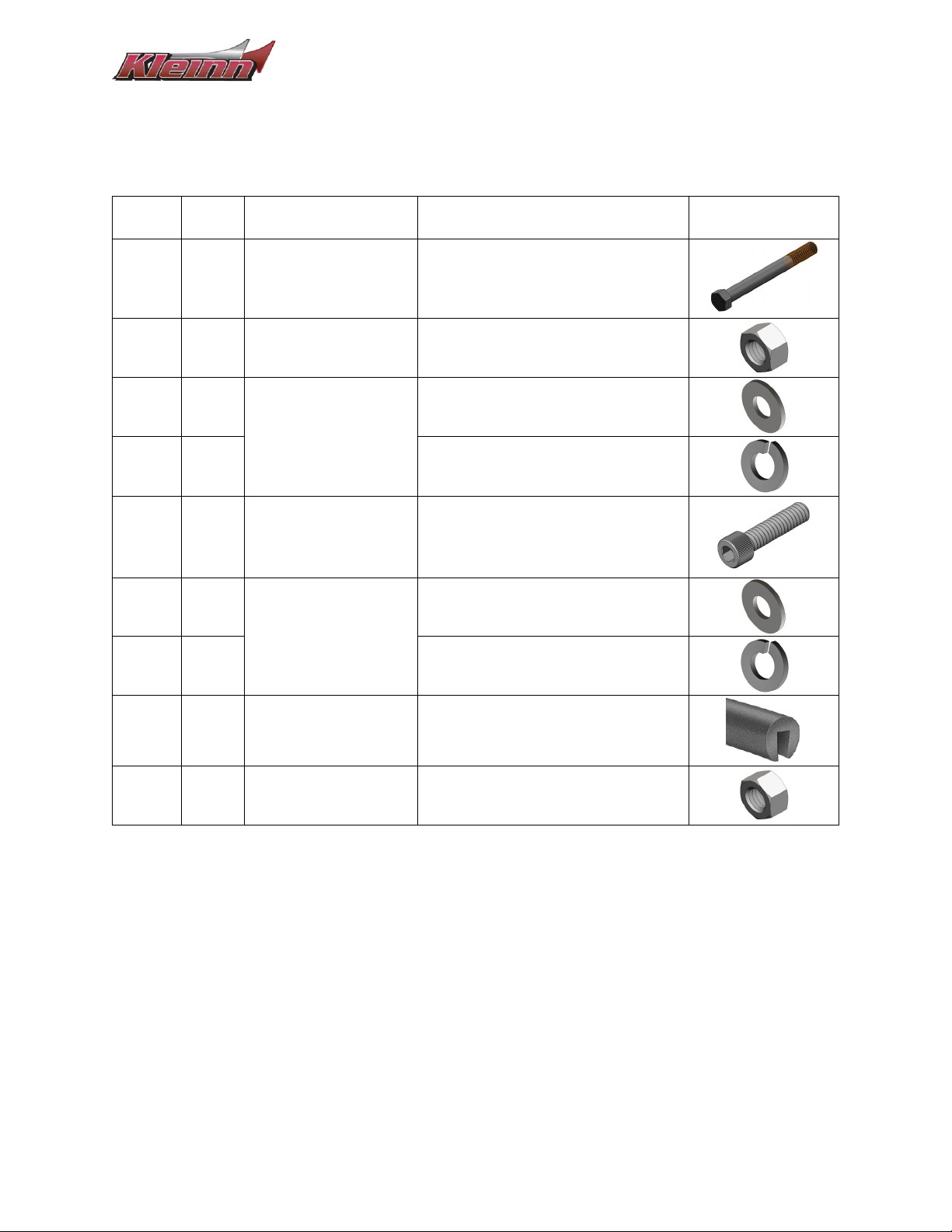

5.5. Hardware & Related Items

Print out the hardware sheets at the end of this section at 100% Scale to facilitate hardware

identification.

Item

No.

Qty Hardware Size Description Picture

H1

4 M10 x 1.5, 100mm

Length Hex Head Bolt

H2

4 M10 x 1.5 Hex Nut

H3

8

M10

Flat Washer

H4

4 Split-Lock Washer

H5

6 1/4"-20, 1” Length Socket Head Cap Screw

H6

8

1/4"

SAE Washer

H7

6 Split-Lock Washer

H8

2 ft - Narrow U-Strip, Rubber *

H9

2 1/4"-20 Hex Nut

*Not Illustrated on the Scale Sheets

NOTE:

SCALE IMAGES OF PRE-PACKAGED HARDWARE INCLUDED WITH

THE COMPRESSOR ARE NOT ILLUSTRATED.

SCALE IMAGES OF UNIQUE & EASILY IDENTIFIABLE HARDWARE ARE

NOT ILLUSTRATED.

THIS DOCUMENT IS DESIGNED TO BE VIEWED / PRINTED AT 100% OR

"ACTUAL SIZE".

ITEM

#

QTY

SCALE IMAGE

H1

4

H2

4

H3

8

H4

4

H5

6

H6

8

H7

6

H8

2 FT

ITEM NOT ILLUSTRATED

H9

2

5/4/2023

SCALE HARDWARE

GMHD20-OBA

1

Install Guide GMHD20-OBA

Page | 11 Revision: A

6. Recommended Routing of Air Tubing & Wire

The below figures are a recommendation of the routing paths for both the air tubing & the wiring. Verify

routing paths, wire lengths, & fuse/relay component locations before cutting the included wire.

Reference Section 9 (On-Vehicle Electrical Installation) for a detailed electrical connection guide.

Figure 2- Recommended Air Tubing Routing

Figure 3- Recommended Electrical Routing (Grounding Points Not Shown)

Install Guide GMHD20-OBA

Page | 12 Revision: A

7. Bench Assembly

7.1. Rubber Trim – Cutting & Installation

1. Cut hardware H8 & run the channel along the curved portions of the tank bracket as shown

below.

Figure 4- Rubber Trim Installation

Install Guide GMHD20-OBA

Page | 13 Revision: A

7.2. Air Tank – Fitting Installation

Using KLEINN Juice, install the associated fittings onto the air tank as shown in the below figure.

Hand tighten the fittings, then further tighten 1/4 - 1/2 turn (or as needed) to match the orientation

shown.

Figure 5- Air Tank Fittings, Orientation & Location

7.3. Compressor – Fitting Installation

1. Using KLEINN Juice, apply 2-3 drops of the thread sealant onto the male threads of the

compressor check valve.

NOTE: Ensure the check valve air outlet hole does not get covered by the JUICE.

2. Install & hand tighten fitting F1 onto the threads and tighten 1/4 to 1/2 turn.

Figure 6- Compressor Fitting Installation

3. Install the 1/4" air tubing onto the compression fitting.

4. Install the inlet filter directly onto the air compressor, or, following the instructions included

with the compressor, route & install the snorkel kit as desired.

7.4. INF-1 – Fitting Installation

1. Use a few drops of the KLEINN Juice & install the INF-1 Fittings to the hose as desired.

Install Guide GMHD20-OBA

Page | 14 Revision: A

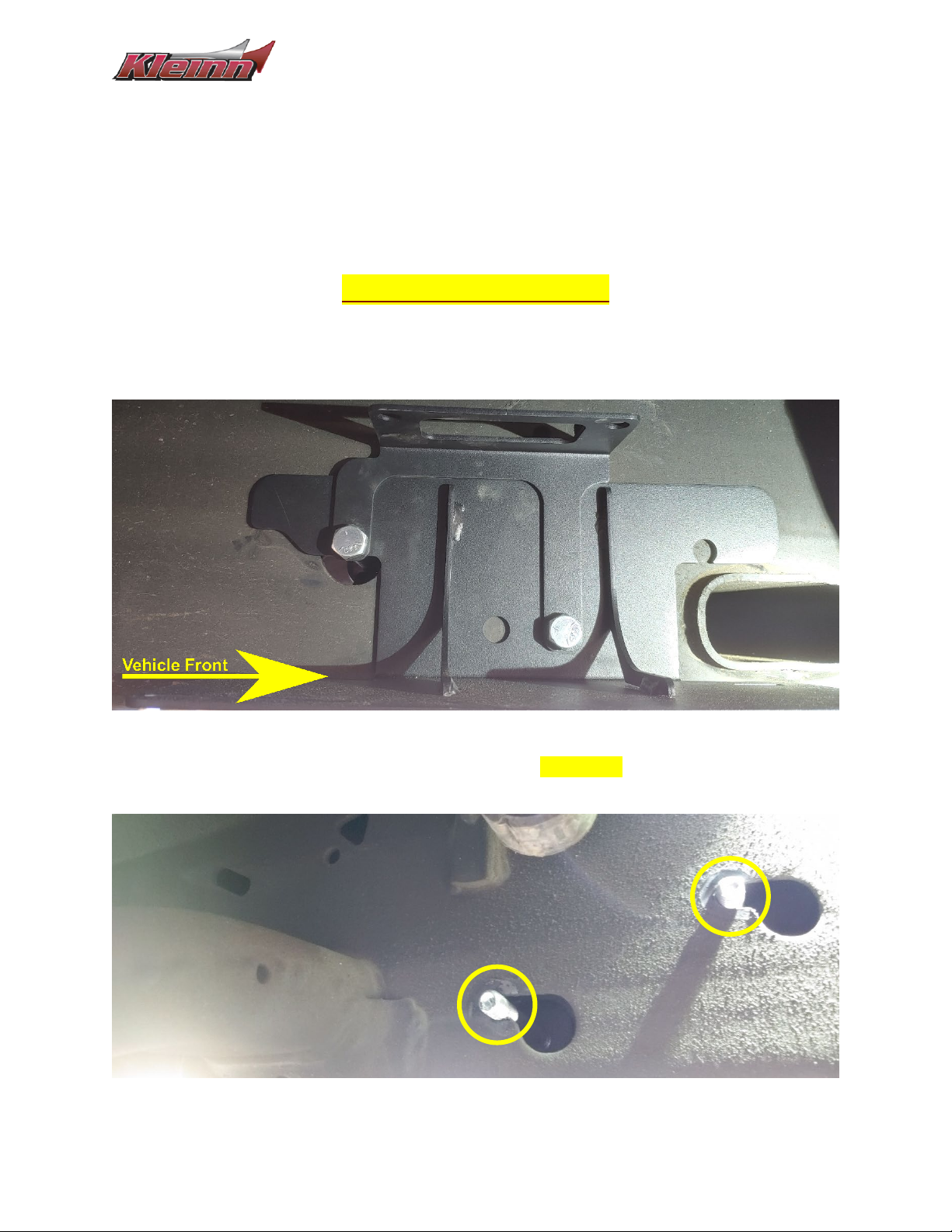

8. On-Vehicle Assembly

8.1. Compressor Installation

The compressor is located on the passenger side of the vehicle, on the outside frame rail, slightly to the

rear of the seam of the front & rear doors.

Figure 7- Compressor Install Location, Passenger Side

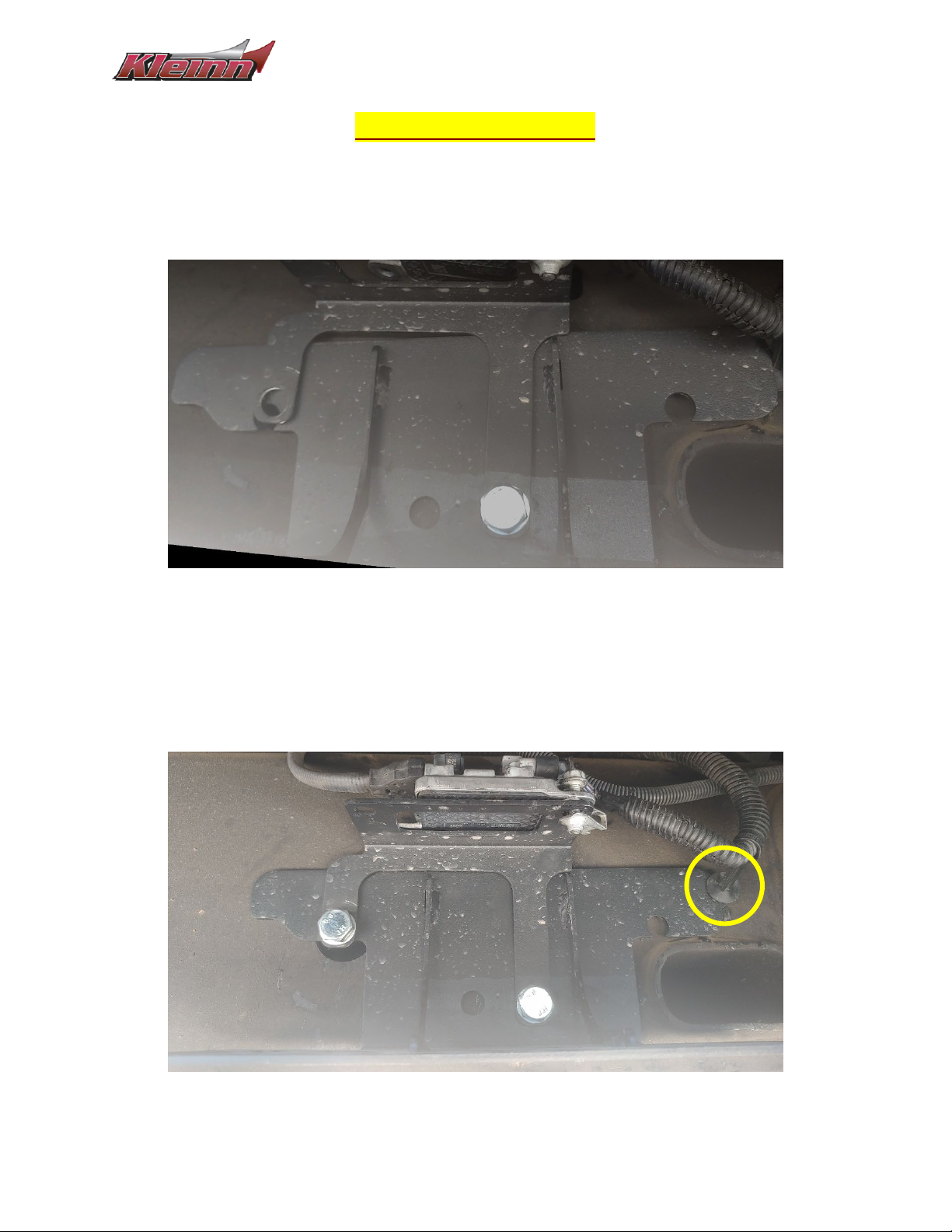

Figure 8- Compressor Bracket, Mounting Points (Above w/o Module, Below w/ Module)

Install Guide GMHD20-OBA

Page | 15 Revision: A

NOTE: If your vehicle has the module that obstructs the compressor bracket location, you will need to use

the included module relocation bracket when installing the compressor bracket.

1. If required, remove the computer module & the frame mounted U-Nuts from the frame rail.

NOTE: Proceed to the following installation steps based on Diesel or Gasoline Engines

For Gasoline Engines Only:

2. Place the compressor bracket onto the correct position on the frame rail and insert hardware H1

through the compressor bracket mounting holes & (if required), through the module relocation

bracket as shown below.

Figure 9- Compressor Bracket Installation, Outside Frame Rail

3. Fully secure the bracket into position using hardware in the order H3, H4 & H2. Ensuring the

threaded section of the bolts are in the upper-left slot of the frame rail as shown below.

Figure 10- Compressor Bracket Installation, Inside Frame Rail

Install Guide GMHD20-OBA

Page | 16 Revision: A

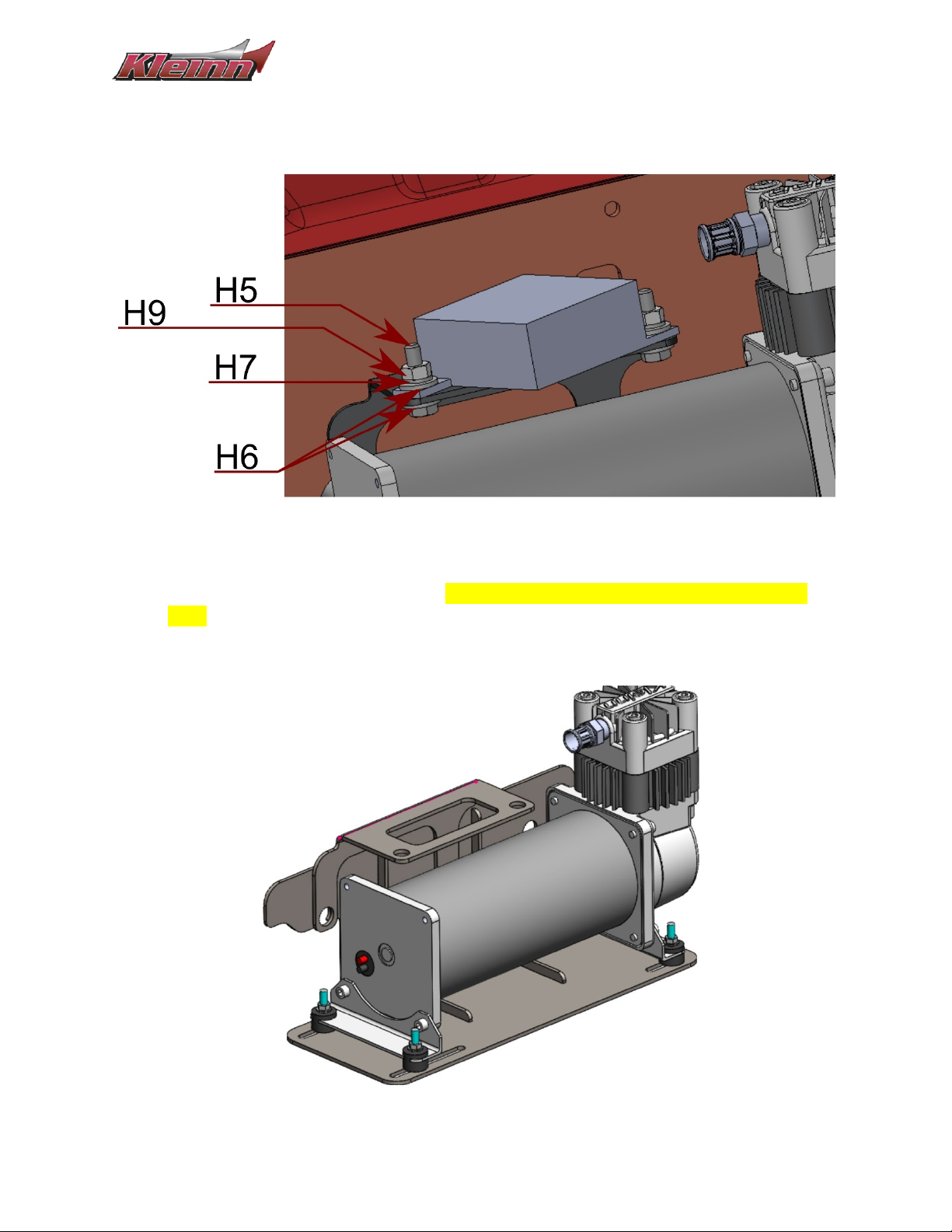

4. If required, use hardware H5, H6, H7 & H9 to install the computer module onto the Module

Relocation Bracket as shown below.

Figure 11- Computer Module, Hardware Stacking Order

5. Place the compressor onto the bracket. The compressor head should be towards the vehicle

front.

6. Use the hardware included in the compressor box & fasten the compressor from the underside

of the bracket as shown below.

Figure 12- Compressor Mounted, Compressor & Hardware Orientation

Install Guide GMHD20-OBA

Page | 17 Revision: A

For Diesel Engines Only:

2. Remove the crossmember’s rightmost bolt that is recessed within the frame rail.

3. Place the compressor bracket onto the correct position on the frame rail and insert hardware H1

through the rightmost bracket mounting hole & (if required), through the module relocation

bracket as shown below.

Figure 13- Compressor Bracket Installation 1, Diesel

4. Allow the bracket(s) to hang & remove the leftmost bolt that is recessed within the frame rail.

5. Slide the compressor bracket into position & insert hardware H1 through the leftmost bracket

mounting hole & (if required), through the module relocation bracket as shown below.

NOTE: To achieve proper alignment, it may be necessary to slightly lift the wiring loom anchor post if it

contacts the compressor bracket.

Figure 14- Compressor Bracket Installation 2, Diesel

Install Guide GMHD20-OBA

Page | 18 Revision: A

6. Fully tighten hardware H1 & (if required), attach the module to the relocation bracket using

hardware H5, H6, H7 & H9 as shown in the above Figure 11.

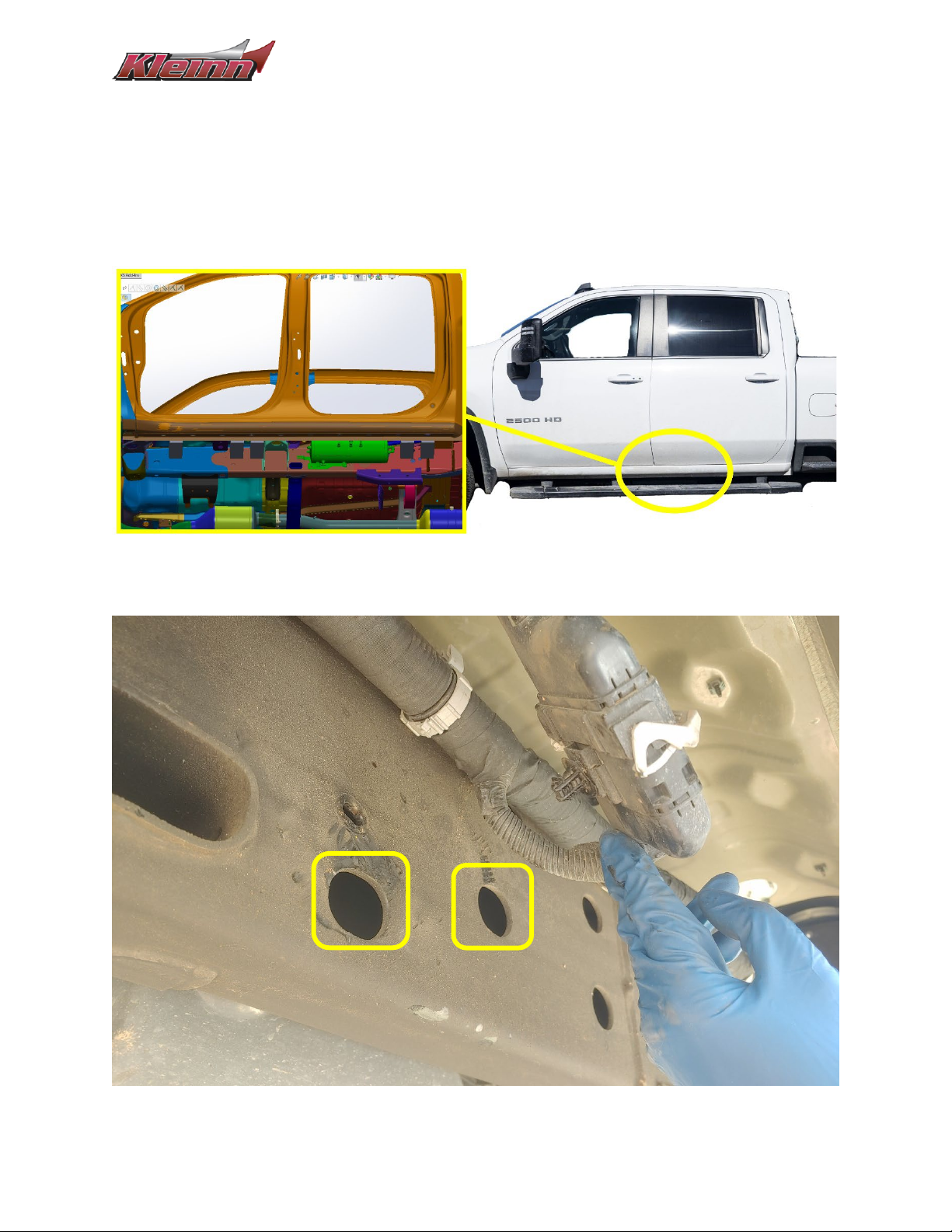

8.2. Tank Installation

The air tank mounts to the outside frame rail (driver side) that is in line with the rear door.

Figure 15- Tank Install Location, Driver Side

Figure 16- Tank Frontmost Bracket, Mounting Point

Install Guide GMHD20-OBA

Page | 19 Revision: A

1. Pry off the electrical connector from the frame rail and move aside to gain access to the tank

bracket mounting location shown in the above figure.

For Gasoline Engines Only:

2. Use hardware H1 to place the tank bracket onto the frame rail. Ensure the threaded portion of

the bolts are in the upper slots of the frame as shown below.

Figure 17- Tank Bracket Installation, Inside Frame Rail

3. Fully secure the bracket into position using hardware H3, H4 & H2,

4. Route the connector wiring and secure the connector to one of the slots on the tab of the tank

bracket as shown below.

Figure 18- Tank Bracket Installation, Connector Placement

Table of contents

Other Kleinn Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction