RAMHDOBA-6450

Install Guide

Go to Table of Contents PG 1/18 REV: A (08/05/2022)

Table of Contents

1. Safety First ..........................................................................................................................................................2

2. Application Chart................................................................................................................................................2

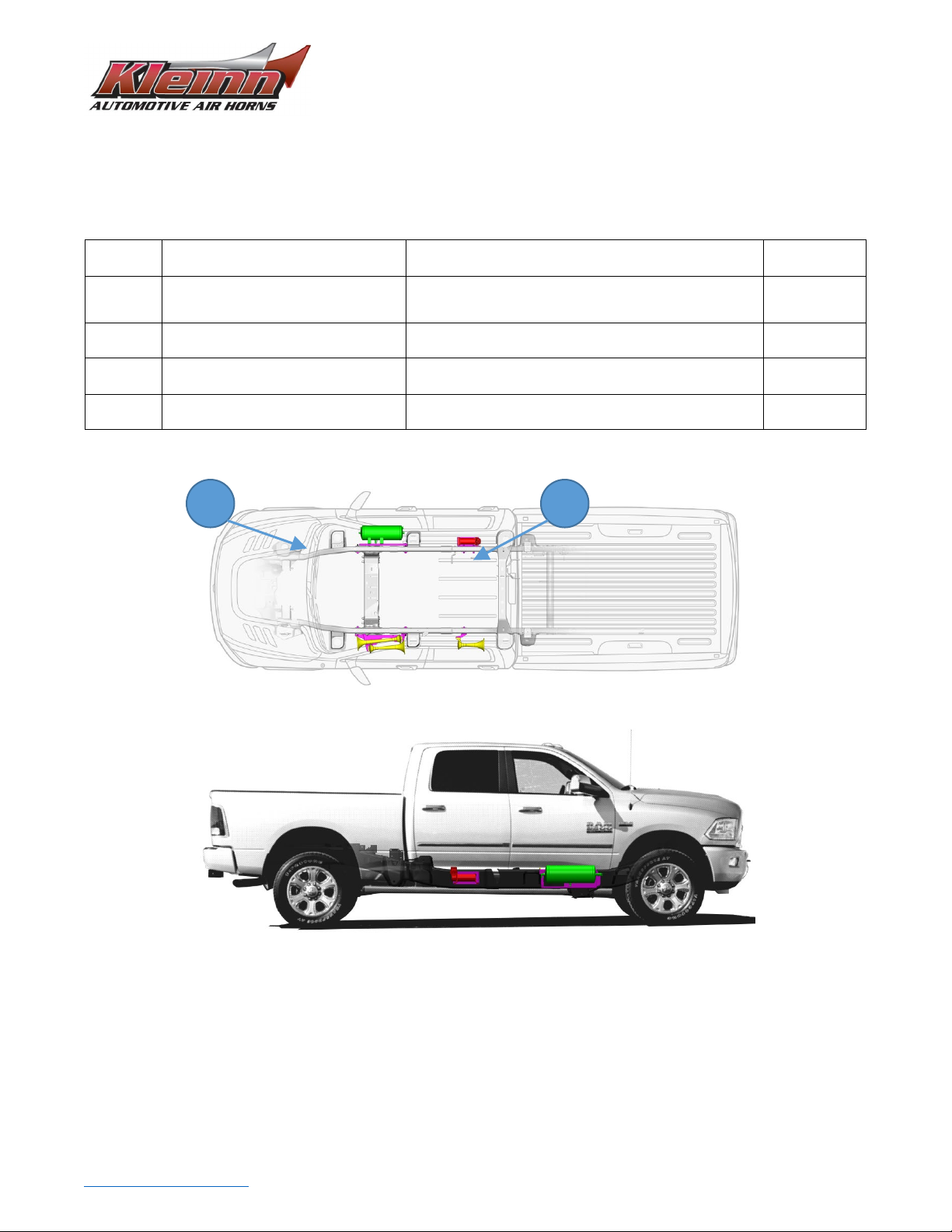

3. Kit Installation Overview ....................................................................................................................................3

3.1. Approximate Installation Time ...................................................................................................................3

4. List of Tools and Supplies ...................................................................................................................................4

4.1. Standard Tool List (Required) .....................................................................................................................4

4.2. Special Tool List (Recommended) ..............................................................................................................4

4.3. Shop Consumables List (Recommended) ...................................................................................................4

5. Parts List .............................................................................................................................................................5

6. Bench Assembly Steps........................................................................................................................................7

6.1. Component Layout .........................................................................................................................................7

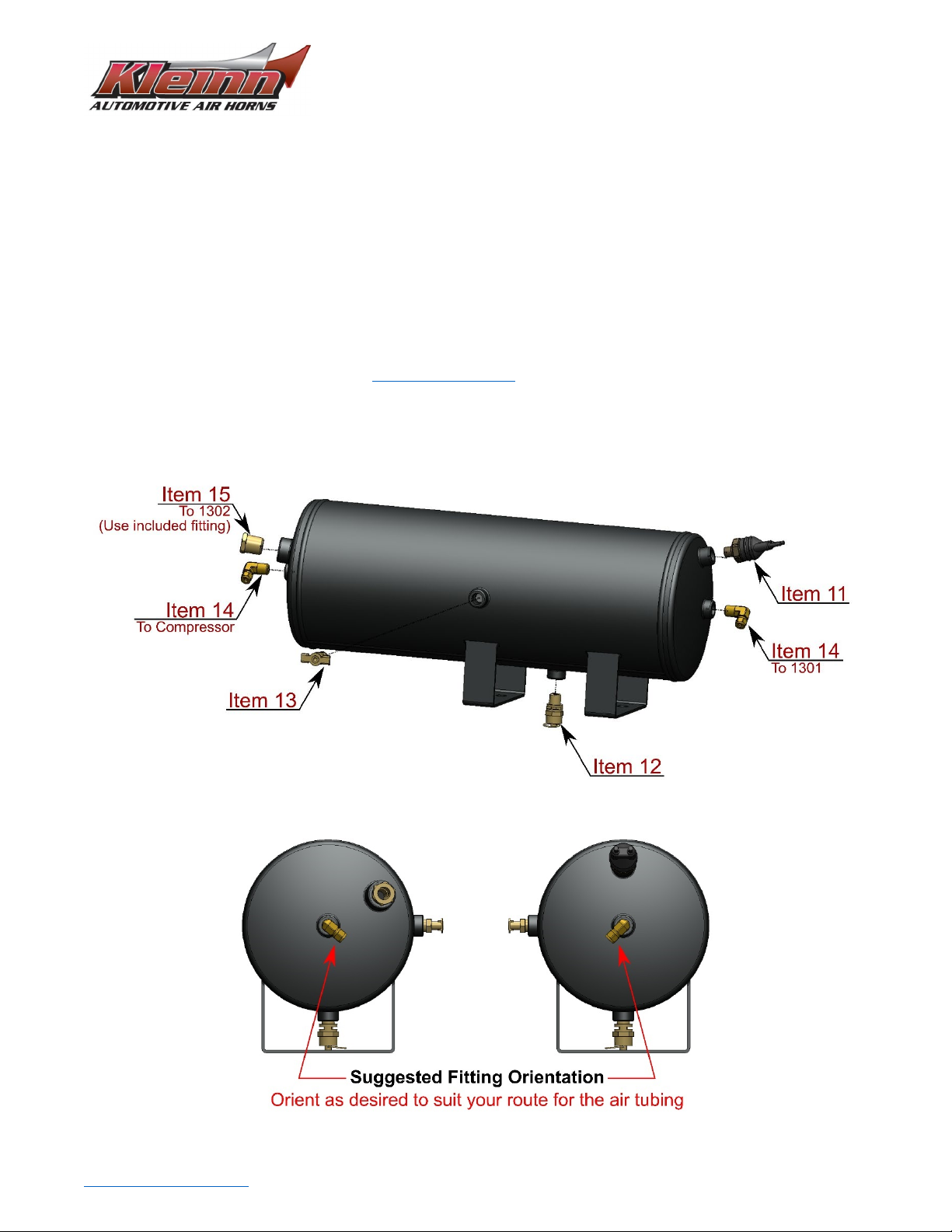

6.2. Air Tank Fittings..............................................................................................................................................7

7. On-Vehicle Assembly..........................................................................................................................................9

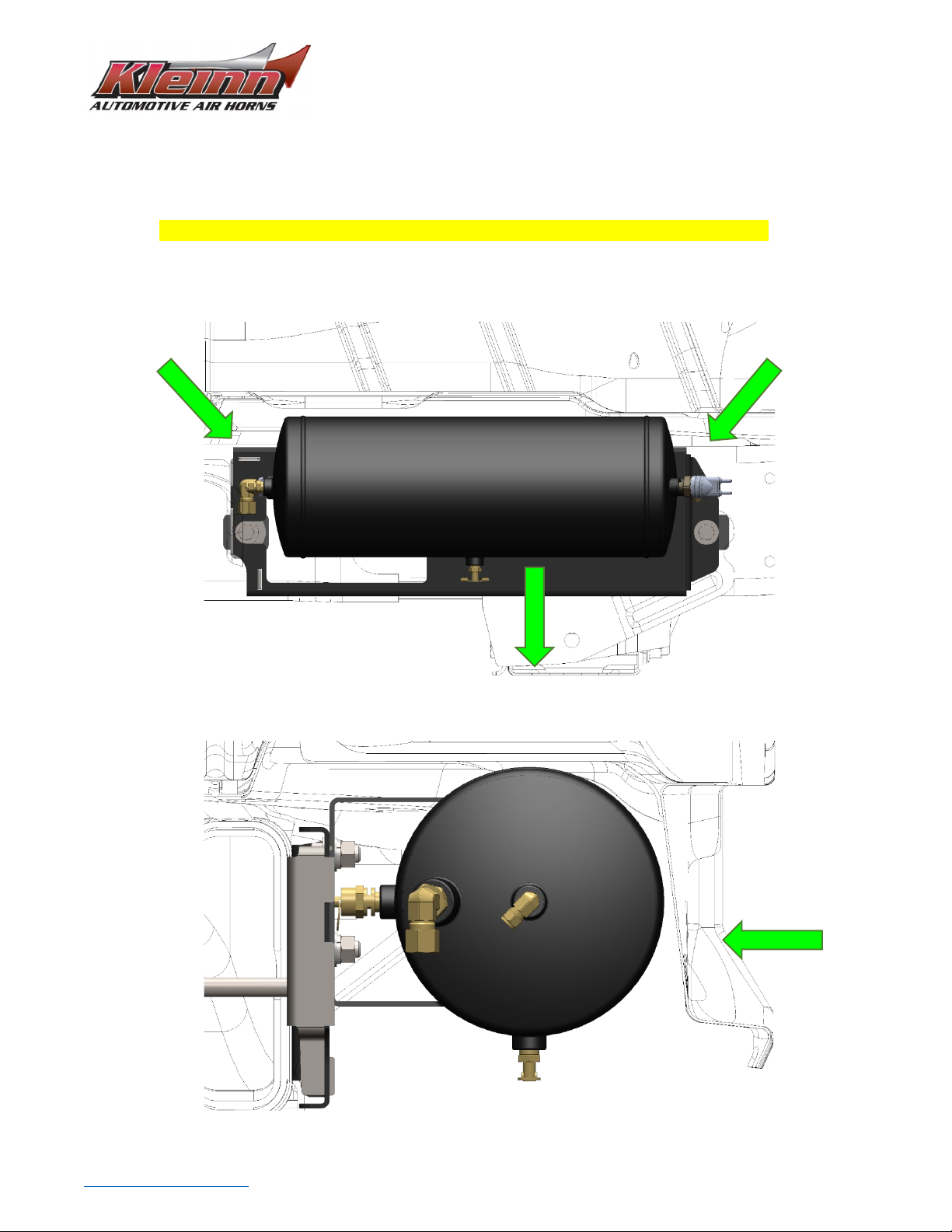

7.1. Air Tank Installation........................................................................................................................................9

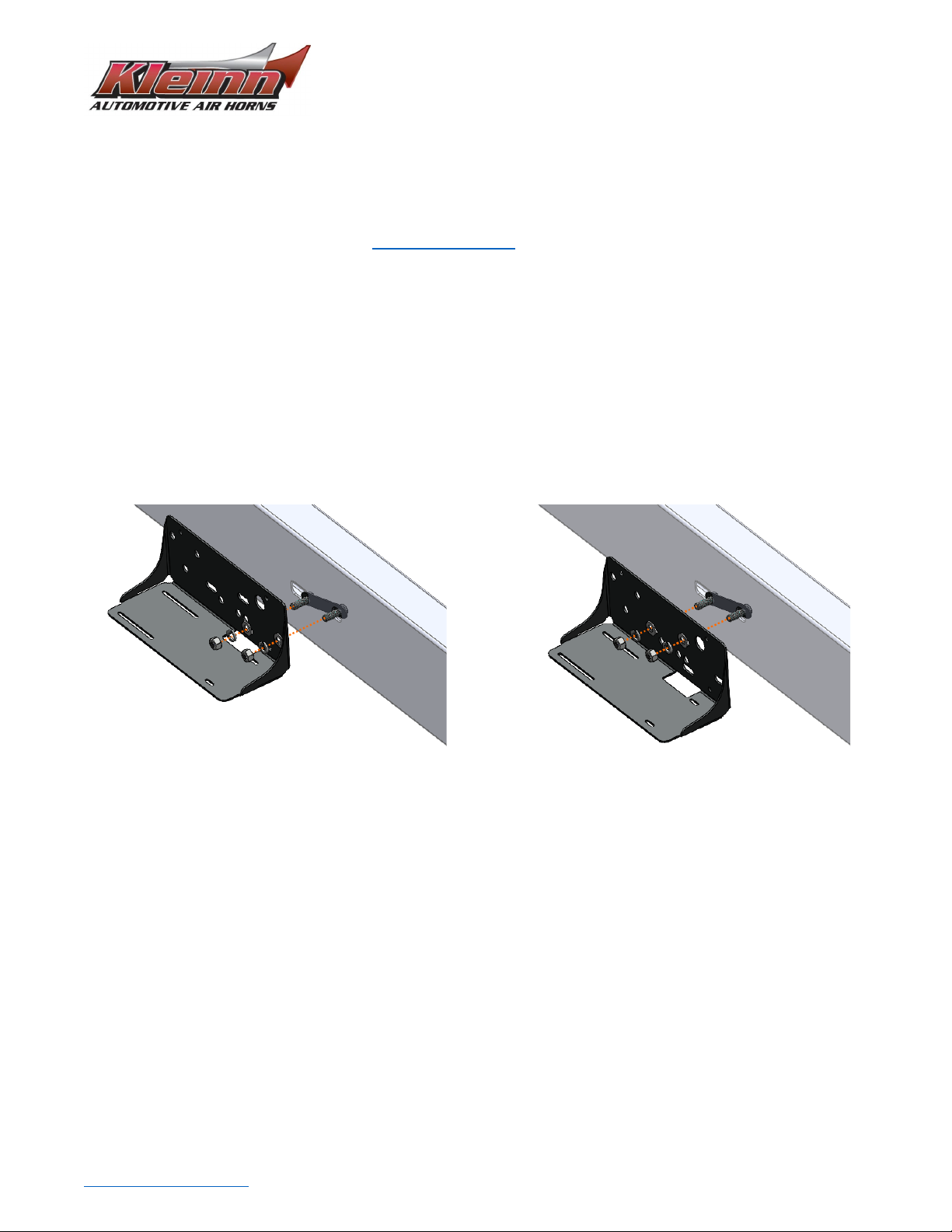

7.2. Compressor & Compressor Bracket Installation ......................................................................................... 11

7.3. 1301 & 1302 Installation ............................................................................................................................. 14

7.4. Air Tubing Routing ....................................................................................................................................... 14

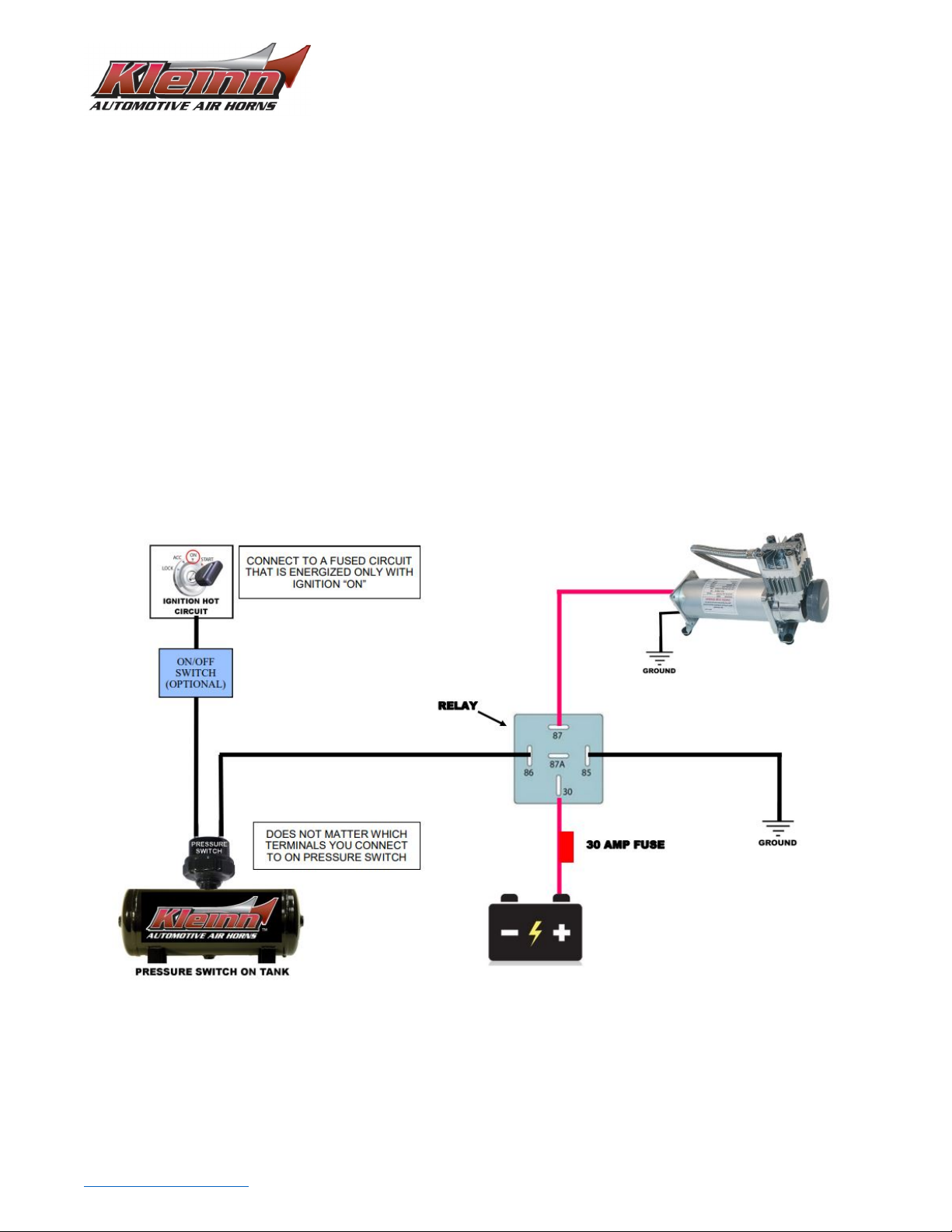

8. On-Vehicle Electrical........................................................................................................................................ 15

8.1. Relay Installation & Wiring .......................................................................................................................... 15

9. Initial Test ........................................................................................................................................................ 16

9.1. Troubleshooting – Compressor Does Not Run............................................................................................ 16

9.2. Troubleshooting – Compressor Does Not Shut Off ..................................................................................... 16

10. Maintenance................................................................................................................................................ 17

10.1. Monthly, or Every 10 Hours of Compressor Run time ............................................................................ 17

10.2. Yearly, or Every 12,000 Miles .................................................................................................................. 17

11. Warranty Information ................................................................................................................................. 18